Zinc phosphide material, zinc phosphide composite material and preparation method and application thereof

A composite material, zinc phosphide technology, applied in phosphorus compounds, chemical instruments and methods, phosphide and other directions, can solve problems affecting actual use, reduce cycle stability, etc., to improve battery performance, make up for reduced conductivity, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

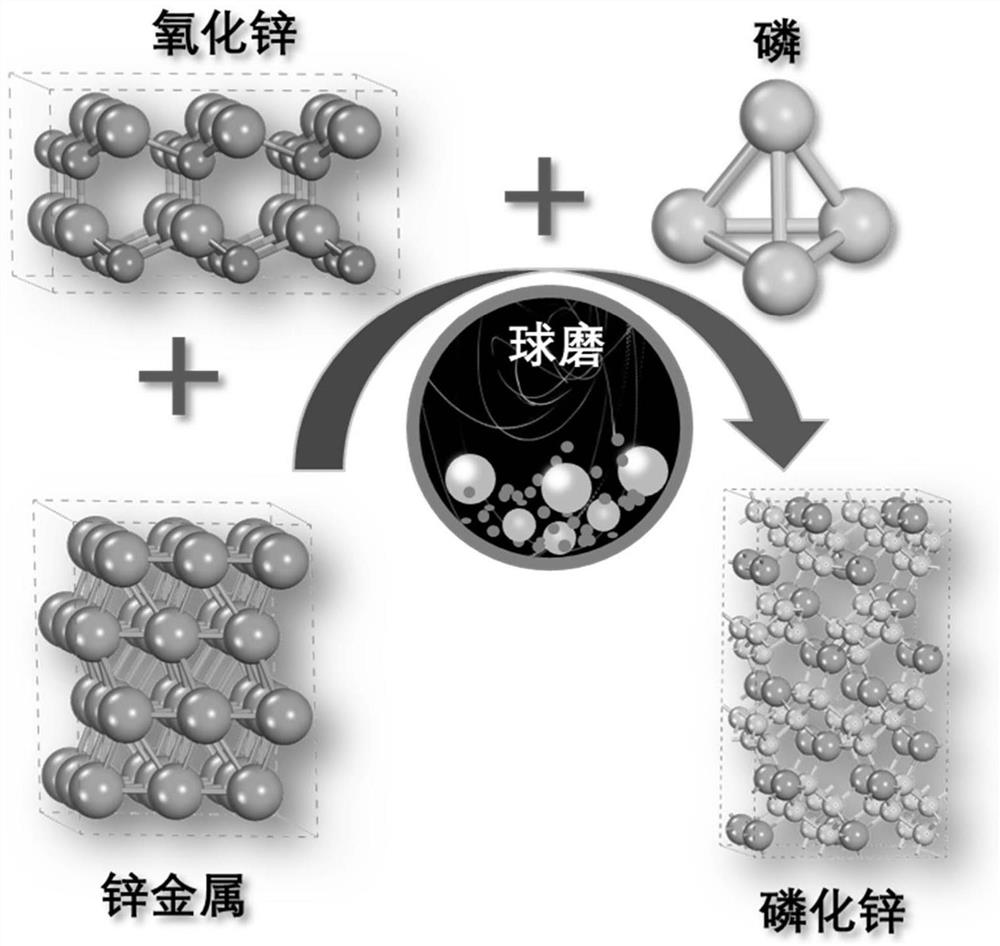

[0032] see figure 1 , Some embodiments of the present invention also provide a method for preparing the above zinc phosphide material, which comprises: ball milling a mixture of metallic zinc, zinc oxide and phosphorus.

[0033] By using zinc oxide, zinc metal and elemental phosphorus as raw materials, the raw material sources are wide and the cost is low, and a relatively stable redox reaction can occur between the three through a simple one-step ball milling process to obtain a certain mass ratio of phosphoric acid Zinc doped zinc phosphide material. That is, the material is obtained by simple ball milling, and the material does not require other post-processing. The cost of raw materials and final products is low, and it is convenient to adjust the zinc phosphate doping ratio through the ratio of raw materials, which is conducive to the large-scale production and use of products.

[0034]In order to make the reaction process more stable and the material uniformity after th...

Embodiment 1

[0051] The present embodiment provides a method for preparing a zinc phosphide material, which is specifically as follows:

[0052] Zn metal (2.2 g) with an average particle size of 20 μm, ZnO (1.0 g) with an average particle size of 200 nm and red phosphorus (2.7 g) with an average particle size of 20 μm were mixed and carried out under an argon atmosphere. In ball milling, the ratio of ball to material is 40:1, the rotation speed is 800 rpm, and the time is 4 h to obtain a zinc phosphate doped zinc phosphide material with a mass fraction of 10 wt %.

Embodiment 2

[0054] The present embodiment provides a method for preparing a zinc phosphide material, which is specifically as follows:

[0055] Zn metal (0.7 g) with an average particle size of 20 μm, ZnO (1.0 g) with an average particle size of 200 nm, and red phosphorus (1.2 g) with an average particle size of 20 μm were mixed and carried out under an argon atmosphere. Ball milling, with a ball-to-material ratio of 40:1, a rotational speed of 800 rpm, and a time of 4 h, to obtain a zinc phosphate-doped zinc phosphide material with a mass fraction of 20 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com