Antibacterial transparent material, preparation method thereof, water storage container and dish washing machine

A technology of transparent materials and transparent plastics, applied in the washing machine/washing machine of tableware, parts of washing machine/rinsing washing machine for tableware, cleaning equipment, etc. problem, to achieve good transparency, excellent long-term antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

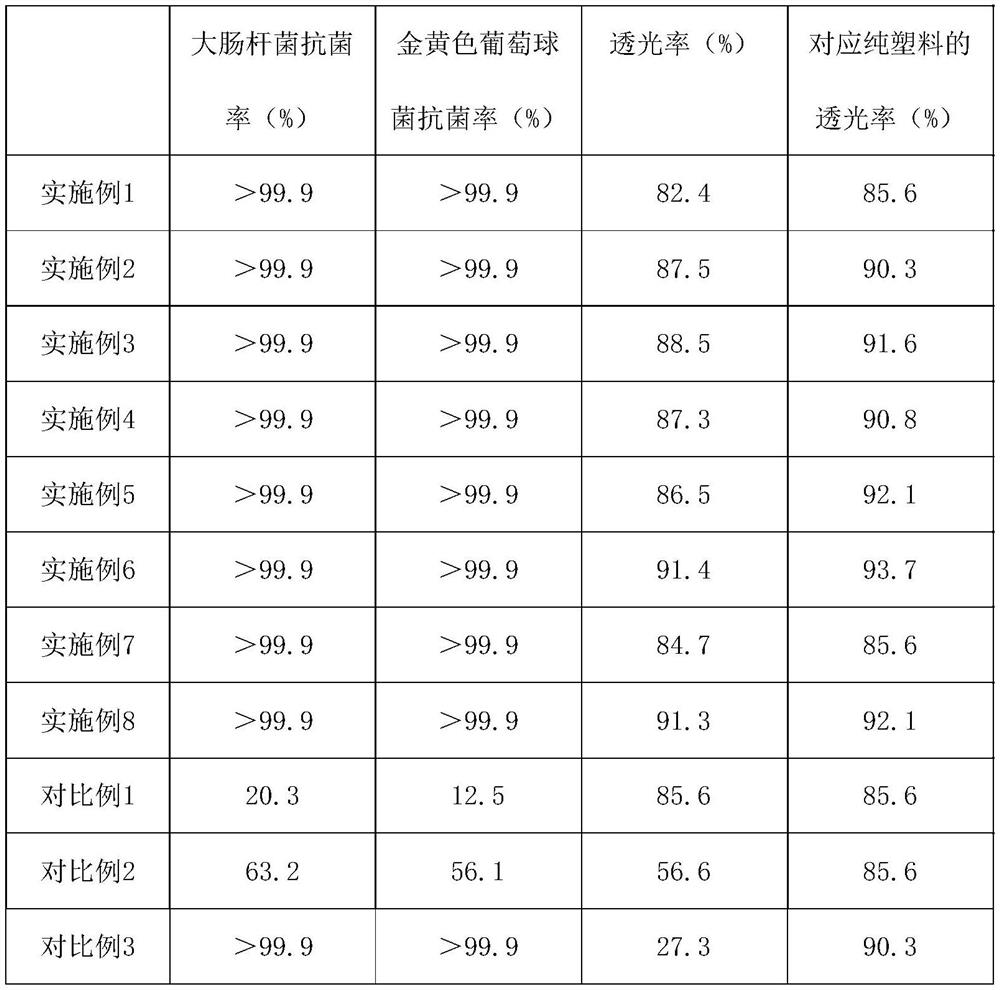

Examples

preparation example Construction

[0042] The preparation method provided by the embodiment of the present invention includes the step of mixing the raw materials and then performing granulation by a twin-screw extruder.

[0043] Further, the raw materials are mixed by mechanical stirring, the stirring speed is 100-400 rpm, and the stirring time is 2-5 min.

[0044] Further, during the granulation process of the twin-screw extruder, the temperature range is controlled at 160-240°C.

[0045] It depends on the type of transparent plastic particles:

[0046] When the transparent plastic particles are polypropylene or polyethylene terephthalate-1,4-cyclohexane dimethanol ester copolymer, the process parameters of the twin-screw extruder granulation are: the temperature of the first zone: 160-180℃ , the temperature of the second zone: 170-190℃, the temperature of the third zone: 180-200℃, the temperature of the fourth zone: 180-200℃, the temperature of the fifth zone: 180-200℃, the temperature of the sixth zone: 18...

Embodiment 1

[0053] This embodiment provides an antibacterial transparent material, the raw material of which is composed of transparent plastic particles PP and antibacterial agents 2-n-octyl-4-isothiazolin-3-one, 2-n-octyl-4-isothiazoline The weight ratio of -3-one to PP was 0.8:100.

[0054] The present embodiment also provides the preparation method of the above-mentioned antibacterial transparent material, and the steps are as follows:

[0055] Accurately weigh 2-n-octyl-4-isothiazolin-3-one and PP according to the above proportions and transfer to a high-speed mixer with a stirring speed of 100 rpm and a stirring time of 3 min. After stirring and mixing evenly, transfer to a twin-screw extruder. Machine feeding hopper ready for extrusion granulation;

[0056] The twin-screw extrusion granulation process parameters are as follows: the temperature of the first zone: 170 °C, the temperature of the second zone: 180 °C, the temperature of the third zone: 180 °C, the temperature of the fo...

Embodiment 2

[0059] This embodiment provides an antibacterial transparent material, the raw material is composed of transparent plastic particles PCTG and antibacterial agent polyhexamethyleneguanidine hydrochloride, and the weight ratio of polyhexamethyleneguanidine hydrochloride to PCTG is 1.0:100.

[0060] The present embodiment also provides the preparation method of the above-mentioned antibacterial transparent material, and the steps are as follows:

[0061] Accurately weigh the polyhexamethyleneguanidine hydrochloride and PCTG according to the above proportions and transfer them to a high-speed mixer. The stirring speed is 300 rpm and the stirring time is 4 min. grain;

[0062] The twin-screw extrusion granulation process parameters are as follows: the temperature of the first zone: 180 °C, the temperature of the second zone: 190 °C, the temperature of the third zone: 190 °C, the temperature of the fourth zone: 190 °C, the temperature of the fifth zone: 190 °C, the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com