A kind of waterproof, moisture-permeable, antibacterial, water-based polyurethane fabric coating adhesive and preparation method thereof

A water-based polyurethane, waterproof and moisture-permeable technology, used in textiles and papermaking, etc., can solve the problems of no waterproof and moisture-permeable performance, no antibacterial performance, complicated process, etc., to avoid the influence of emulsion stability, and to achieve excellent waterproof and moisture-permeable performance. , the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

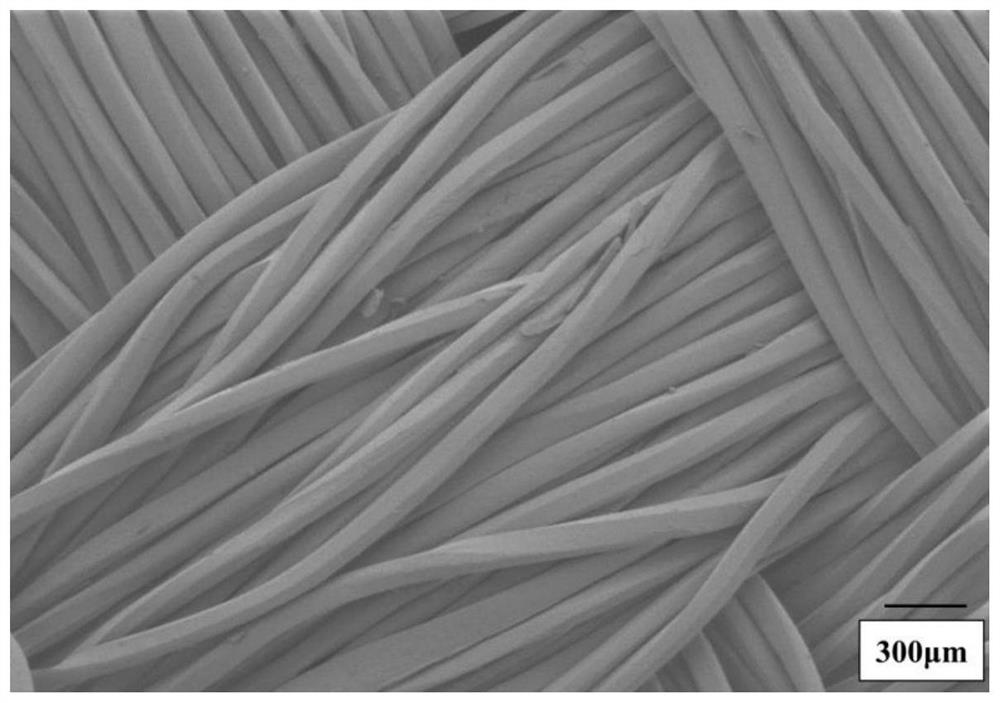

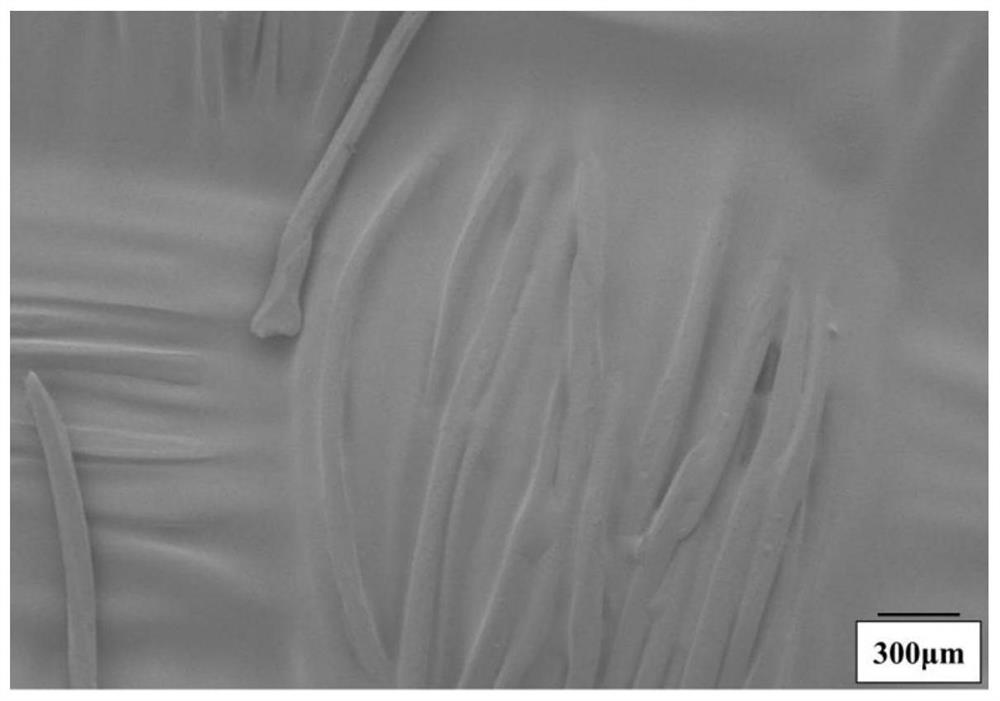

Image

Examples

Embodiment 1-3

[0030] The hydrophilic end-capping agents used in Examples 1-3 were all prepared according to the following steps:

[0031] 2.7kg monohydroxycarboxylic acid (specifically malic acid MA in Example 1-3), 14kg low molecular weight polyether alcohol (specifically MPEG in Example 1-3, Mn=350) and 0.2kg catalyst (Example 1 -3, specifically p-toluenesulfonic acid) was dissolved in 80 L of toluene, reacted at 140 °C for 24 h, and after the reaction was completed, the solvent was evaporated at 55 °C to obtain a polyethylene oxide group-containing hydrophilic end-capping agent (MMPEG) .

Embodiment 1

[0033] The preparation of waterproof and moisture-permeable water-based polyurethane emulsion: 10kg of polymer polyol (specifically selected polycaprolactone diol PCL in this example, Mn=1000, the same as in Examples 1-3), 2kg of organosilicon (in this example) Specifically, hydroxypropyl-terminated polydimethylsiloxane PDMS was selected, Mn=1000, the same as in Example 1-3), added to the reactor at 120 °C for vacuum dehydration for 2 h, and 7.8 kg of aliphatic diisocyanate (specific in this example) was added. is isophorone diisocyanate (IPDI), react at 90°C for 2h; cool down to 50°C, add 1.35kg small molecule chain extender (specifically 1,4-butanediol BDO in this embodiment) and 7g organotin catalyst ( In this example, it is specifically stannous octoate T-9), reacted at 75°C for 3h, and added 5kg of acetone during the reaction to adjust the viscosity; cooled to 50°C, added 3.7kg of the hydrophilic end capping agent MMPEG, followed by the reaction for 3h; lowered to 30°C Ne...

Embodiment 2

[0037] A method for preparing a waterproof, moisture-permeable, antibacterial, water-based polyurethane fabric coating adhesive, wherein the precoat layer is composed by weight: 80 parts of a waterproof and moisture-permeable water-based polyurethane emulsion, 0.15 parts of a silicone-based defoamer, and a polyurethane associative thickener. 1.5 parts of agent, 2 parts of polyhexamethyleneguanidine hydrochloride.

[0038] Preparation of waterproof and moisture-permeable water-based polyurethane emulsion: add 10kg PCL and 2kg PDMS to the reactor for vacuum dehydration at 120°C for 2h, add 7.8kg IPDI, and react at 90°C for 2h; cool down to 50°C, add 1.35kg BDO and 7g T-9 , react at 75°C for 3h, and add 5kg of acetone during the reaction to adjust the viscosity; cool to 50°C, add 5kg of MMPEG, and then react for 3h; drop below 30°C, add 61kg of 5% tannic acid aqueous solution for high-speed shear emulsification for 20min , and after removing the acetone, a waterproof and moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com