White tungsten flotation process capable of improving tungsten recovery rate

A technology of recovery rate and scheelite, which is applied in flotation, cleaning method using liquid, separation method, etc., can solve problems such as hearing health damage, achieve the effect of improving recovery rate, reducing noise generation rate, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

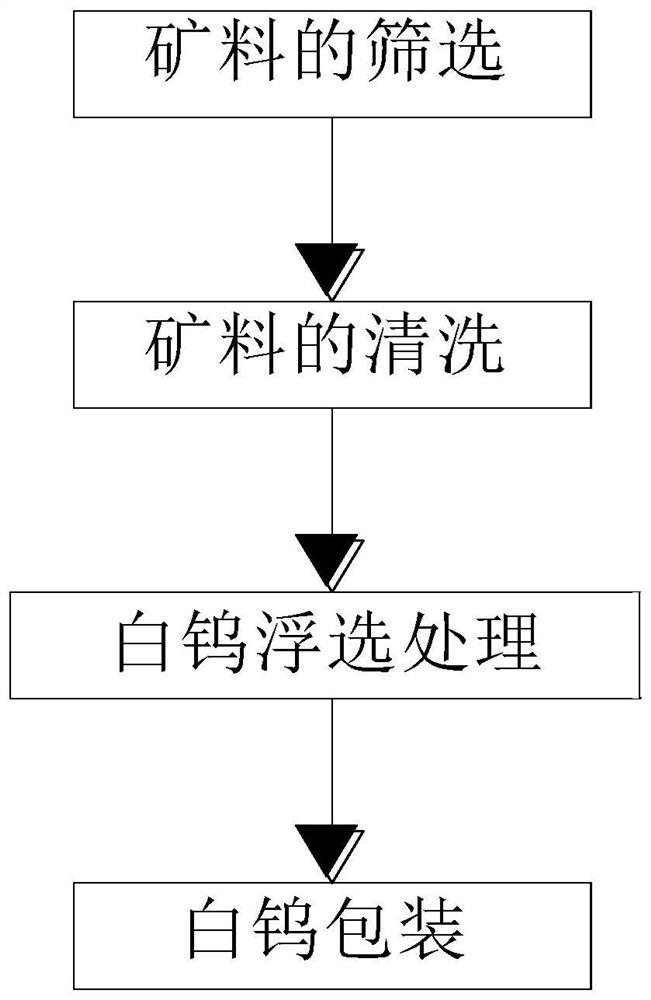

[0046] like Figure 1-10 As shown, the present invention provides a scheelite flotation process for improving tungsten recovery rate, and the scheelite flotation process for improving tungsten recovery rate includes the following steps:

[0047] Step 1. Screening of mineral material: firstly remove the foreign matter inside the mineral material manually, and then use a screening device to screen out the larger and smaller impurities inside the mineral material;

[0048] Step 2, cleaning of mineral material, specifically:

[0049] Step A1. Add 20w% of modified tea saponin, 8w% of natural soap solution, 12w% of ethanol, 10w% of distilled water, 15w% of heavy cellulase and 35w% of Sapindus mucinus extract into the constant temperature mixing and stirring tank, and stir the mixture. The time is set to 18MIN, and the temperature is controlled to 63±3 degrees Celsius. After the stirred solution is cooled to room temperature, the detergent is obtained;

[0050] Step A2: Add the scr...

Embodiment 2

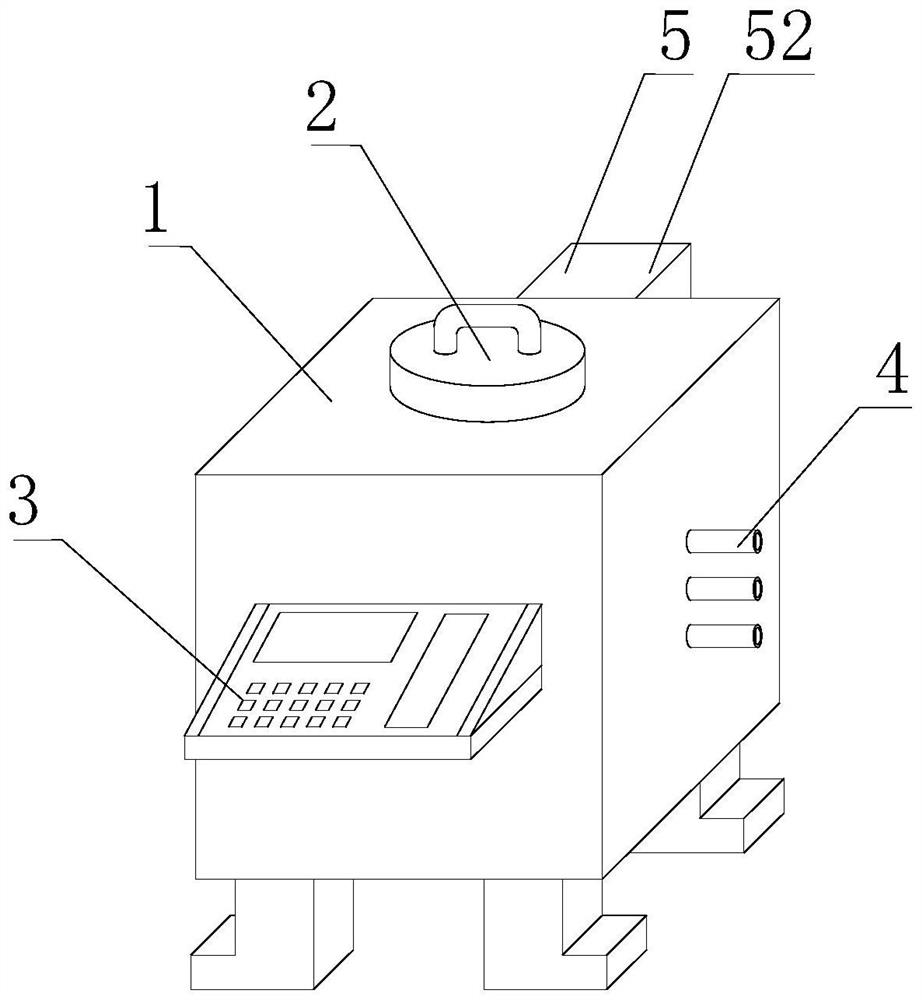

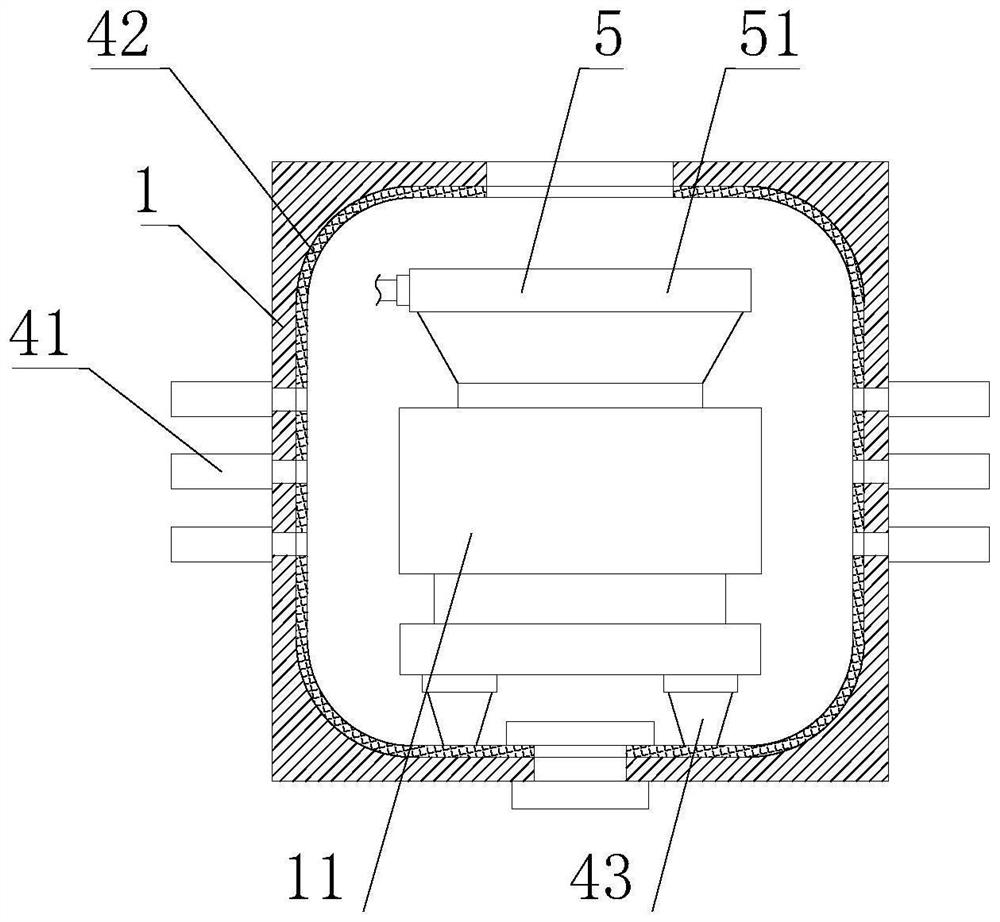

[0058] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the regrinding device includes a grinding box 1 and a grinding machine body 11, and the top of the grinding box 1 is detachably connected with a top cover 2 , the bottom of the grinding box 1 is detachably connected with a bottom cover, the front of the grinding box 1 is fixedly installed with a control panel 3, the inner cavity of the grinding box 1 is provided with a noise reduction mechanism 4, and the back of the grinding box 1 is provided with There is a dust suppression mechanism 5, and the noise reduction mechanism 4 includes a ventilation and noise reduction pipe 41, a sound insulation lead plate 42 and a shock absorption support 43. The sound insulation lead plate 42 is fixedly connected to the inner wall of the grinding box 1, and the ventilation noise reduction pipe 41 is fixedly connected to the grinding machine. On the outer wall of the...

Embodiment 3

[0060] like Figure 1-10 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the dust suppression mechanism 5 includes an inlet ring 51 and a dust suppression cylinder 52, the inlet ring 51 is fixedly installed on the top of the grinder body 11, and the inlet ring 51 A metal mesh pipe 511 is fixedly connected to the inner wall of the inlet ring 51, and a connecting air pipe 521 is fixedly connected to the outer wall of the inlet ring 51. The dust suppression cylinder 52 is fixedly installed on the back of the grinding box 1, and the connecting air duct 521 is far away from the inlet ring 51. One end of the dust suppression cylinder The top of 52 is fixedly connected, an inner partition 522 is fixedly installed on the inner wall of the dust suppression cylinder 52, and a water treatment cylinder 523 is fixedly installed on the inner wall of the inner partition 522. The bottom of 523 is fixedly connected with a sewage pipe, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com