Method for preparing porous carbon material from humin and porous carbon material

A porous carbon material, black technology, applied in the application field of humin, can solve the problems of limited large-scale application, numerous steps, high energy consumption, etc., and achieve the effects of large-scale production application, simple preparation process and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

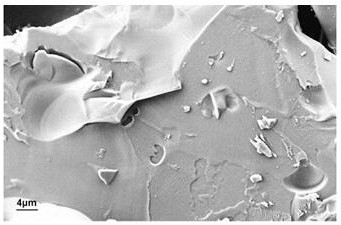

[0027] Embodiment 1: a method for preparing porous carbon material from humin, comprising the following steps:

[0028] 1) Add humin and potassium permanganate (mass ratio 1:0.05) into a mixed solution of water and ethanol (volume ratio 1:0.5), stir at room temperature for 8 hours, and dry in an oven at 80°C to obtain a black solid ;

[0029] 2) Put the black solid into a tube furnace protected by helium gas, and calcine it at 300℃ for 1h;

[0030] 3) After cooling, take out the black solid and repeatedly rinse with deionized water and 1 mol / L acetic acid solution to obtain the biomass porous carbon material. Its BET test data is shown in Table 1.

Embodiment 2

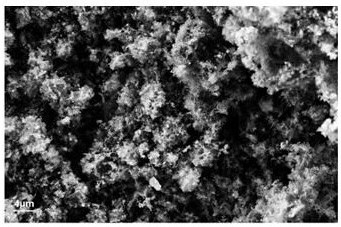

[0031] Embodiment 2: a method for preparing porous carbon material from humin, comprising the following steps:

[0032] 1) Add humin and potassium permanganate (mass ratio 1:0.1) into a mixed solution of water and ethanol (volume ratio 1:3), stir at room temperature for 12 hours, and dry in an oven at 120°C to obtain a black solid ;

[0033] 2) Put the black solid into a tube furnace protected by helium gas, and calcine it at 900℃ for 1h;

[0034] 3) After cooling, take out the black solid and repeatedly rinse with deionized water and 6 mol / L acetic acid solution to obtain the biomass porous carbon material. Its BET test data is shown in Table 1.

Embodiment 3

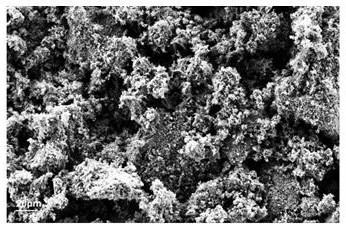

[0035] Embodiment 3: a kind of method for preparing porous carbon material by humin, specifically comprising the following steps:

[0036] 1) Add humin and potassium permanganate (mass ratio 1:0.2) into a mixed solution of water and ethanol (volume ratio 1:3), stir at room temperature for 16 hours, and dry in an oven at 110°C to obtain a black solid ;

[0037] 2) Put the black solid into a tube furnace protected by helium gas, and calcine it at 900℃ for 2h;

[0038] 3) After cooling, take out the black solid and repeatedly rinse with deionized water and 3 mol / L acetic acid solution to obtain the biomass porous carbon material. Its BET test data is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com