Structural flame-retardant high-strength low-heat polymer grouting material for reinforcement

A grouting material and structural technology, applied in the field of polyurethane materials, can solve problems such as small molecular weight, heavy metal catalyst poisoning, air pollution, etc., and achieve the effect of uniform functionality, high cross-linking density, and low cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

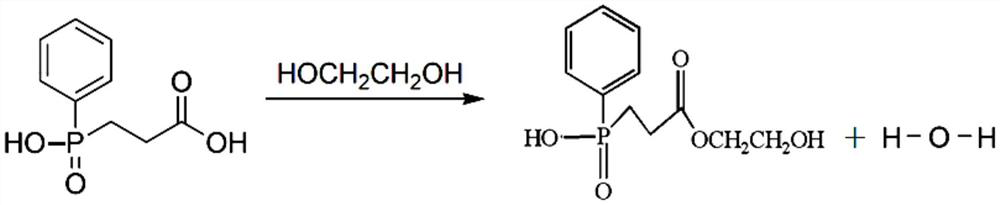

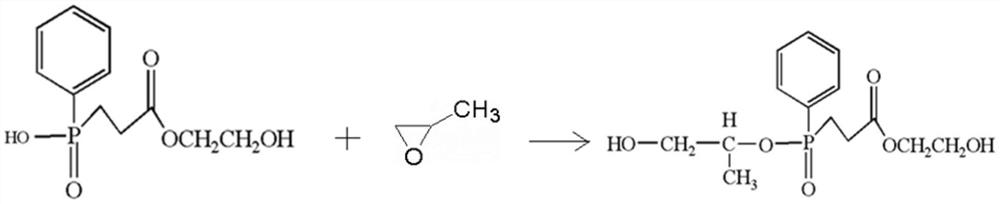

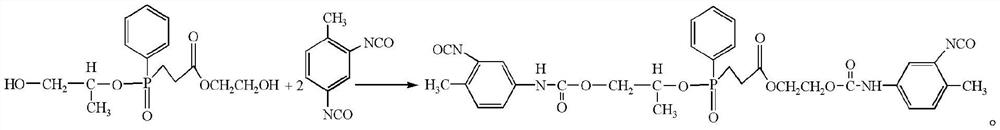

Method used

Image

Examples

Embodiment 1

[0044] A structural flame-retardant, high-strength, low-heat-release polymer grouting material for reinforcement in this embodiment is formed by polymerizing a modified isocyanate component and a polyol component. The quality of the modified isocyanate component and the polyol component is The ratio is (100-160): 100, and the chemical structural formula of the modified isocyanate is as follows:

[0045]

[0046] The P content of the modified isocyanate was 4.4%, the N content was 7.9%, and the NCO% content was 11.9%.

[0047] The polyol components include: polyether polyol with sorbitol having a functionality of 6 as an initiator, 4,4'-bis-sec-butylaminodiphenylmethane, silicone oil, and reactive additives, among which the sorbitol having a functionality of 6 The polyether polyol with sorbitol as the initiator accounts for 50-70% of the total weight of the polyol component; 4,4'-bis-sec-butylaminodiphenylmethane accounts for 25-45% of the total weight of the polyol componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com