Desktop type device and method for sample thickness in-situ measurement under static high pressure

A technology of sample thickness and high-voltage device, which is applied in the direction of measuring device, wave/particle radiation, image analysis, etc., can solve the problems of complicated operation, high experimental cost, and large space occupation, and achieve simple operation and no use cost , the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

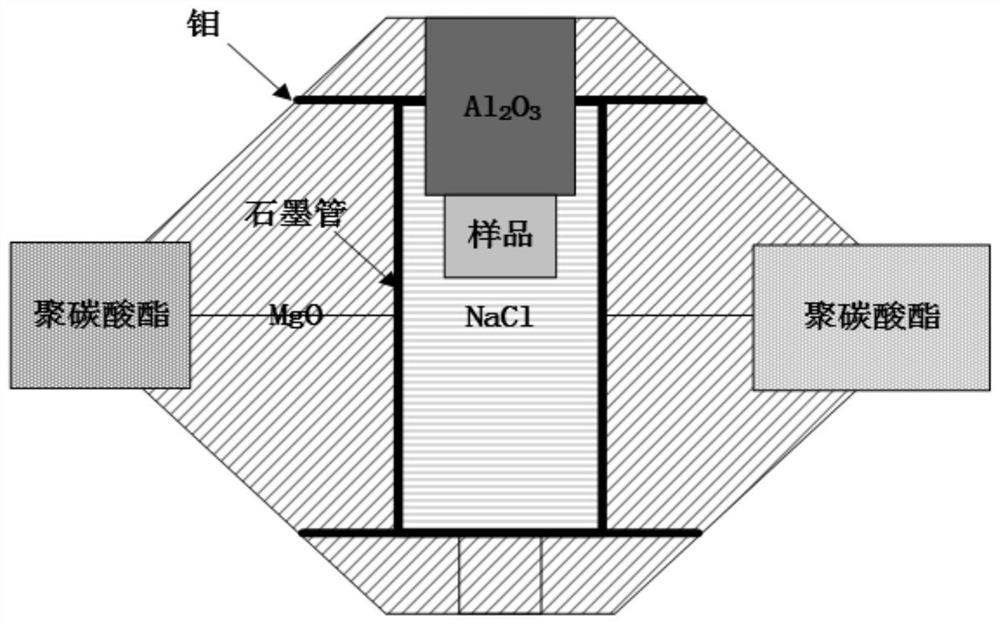

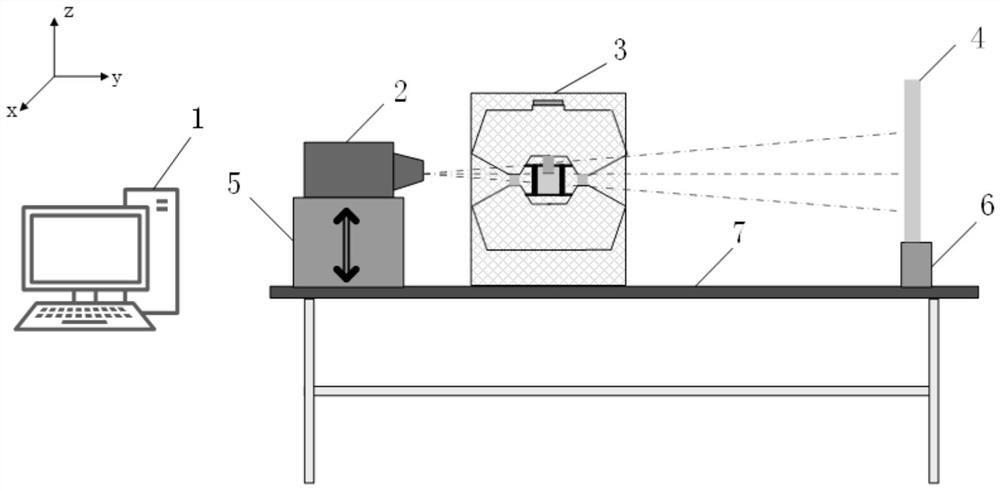

[0052] like Figure 1 to Figure 4 As shown, the present invention is a desktop device for in-situ measurement of sample thickness under static high pressure. The present invention uses a microfocus X-ray machine to replace the synchrotron radiation light source in the traditional scheme to measure the sample thickness in the high-pressure sound velocity experiment on-site, and at the same time By changing the overall layout of each component in the device, and in combination with the measurement method proposed by the present invention, measurement accuracy basically equivalent to that of the synchrotron radiation light source solution can be achieved at a low cost.

[0053] like figure 2 As shown, the device includes a control computer 1, a microfocus X-ray machine 2, a large cavity high-voltage device 3, an X-ray image detector 4, an X-ray machine displacement system 5, a detector displacement system 6 and a vibration isolation optical platform 7;

[0054] The microfocus X...

Embodiment 2

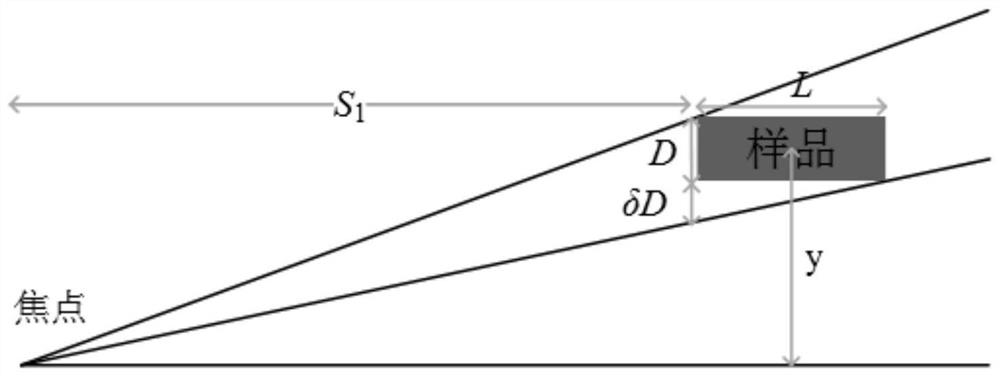

[0076] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment provides a method for in-situ measurement of sample thickness under static pressure, and this method is applied to the described method for in-situ measurement of sample thickness under static pressure the desktop device; the method comprising:

[0077] Carry out the layout setting of each system in the desktop device for in-situ measurement of sample thickness under static pressure;

[0078] Scan the Z-axis position of the microfocus X-ray machine 2, and collect a projected image of the sample at each position;

[0079] Fitting the position of the upper and lower surfaces of the sample to be tested in the projection image, and measuring the number of pixels occupied by the sample to be tested, the thickness of the sample to be tested is obtained;

[0080] Determine the minimum thickness of the sample to be measured according to the Z-axis position of the microfocu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com