Low-cost and high-efficiency pollutant and CO2 synergistic absorption-desorption decoupling method

A pollutant and low-cost technology, applied in the direction of separation methods, chemical instruments and methods, control/regulation systems, etc., can solve the problems of high cost of solid absorbent, high technical difficulty, waste of sulfur resources, etc., and achieve collaborative capture energy Low consumption, guaranteed absorption efficiency, guaranteed absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

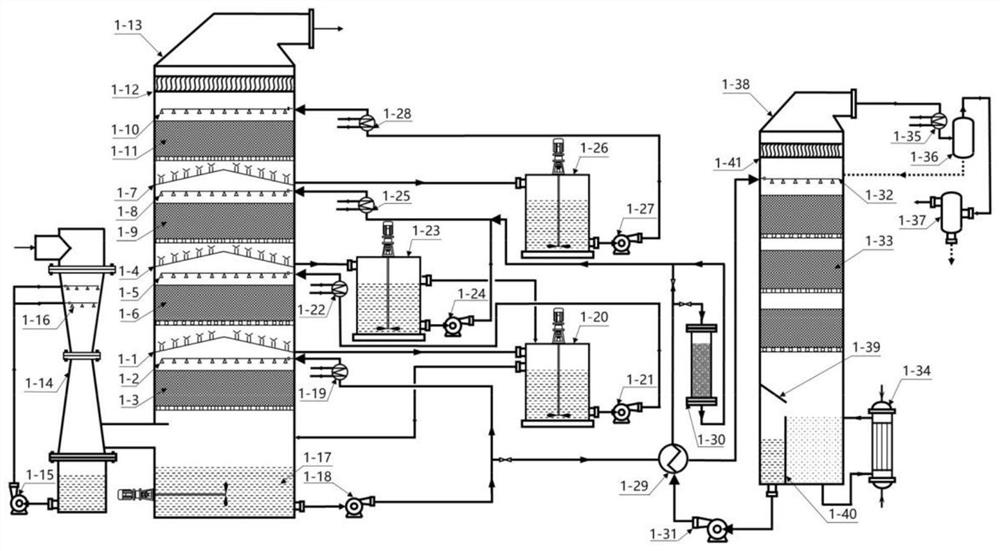

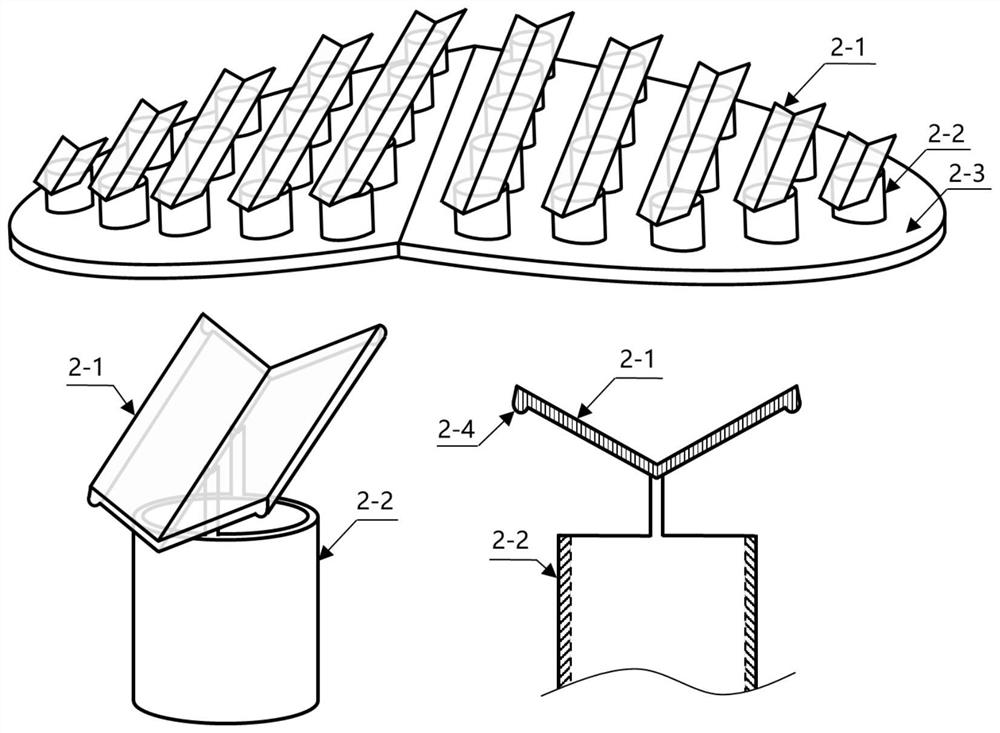

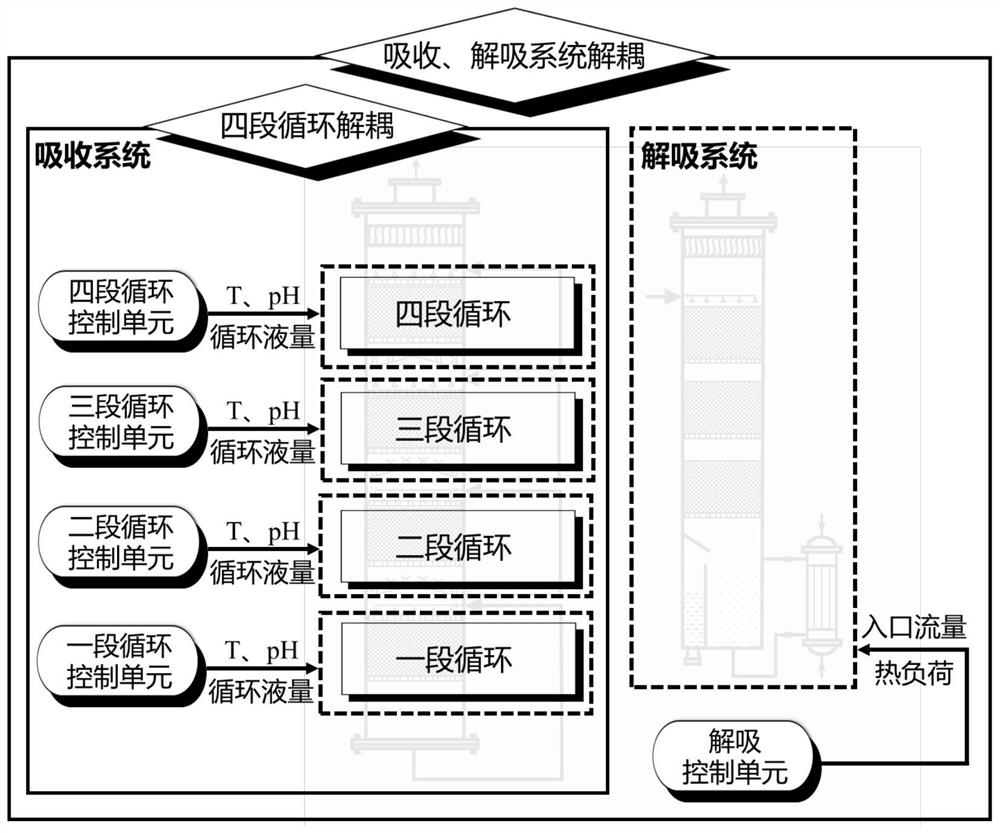

[0078] refer to Figures 1 to 3 , a low-cost and efficient pollutant associated with CO 2 In the coordinated absorption-desorption decoupling method, the flue gas enters the absorption system. The absorption system includes a multi-stage circulating absorption tower. After passing through the pre-washing section set at the front of the multi-stage circulating absorption tower, it enters the first-stage pollutant absorption section and the second-stage CO in turn. 2 Absorption stage, three stage CO 2 The absorption section and the four-stage water washing section; the rich liquid enters the desorption system through the lean and rich liquid heat exchanger, and the desorption system includes a desorption tower. The system and the desorption system are respectively controlled by a decoupling control system. The decoupling control system includes the absorption control unit of the multi-stage circulating absorption tower and the desorption control unit of the desorption tower. Th...

Embodiment 2

[0129] For the flue gas of power plants burning high-sulfur coal containing N 2 and part O 2 In addition, it contains about 10% water vapor, 12% to 18% CO 2 and 1000~1500ppm SO 2 Wait.

[0130]The first-stage circulation control unit is respectively connected with the first-stage circulation tank 1-17, the rich liquid pump 1-18 and the first-stage circulating cooler 1-19, and controls the first-stage circulation independently. The first-stage circulation control unit controls the pH of the absorption liquid in the first-stage circulation tank 1-17, the flow rate of the rich liquid pump circulation 1-18 and the cooling water flow of the first-stage circulating cooler 1-19, so that the first-stage circulation pH is 5.2, and the circulating liquid-gas ratio is 1.8L / m 3 , the absorption temperature is 54 ℃.

[0131] The second-stage circulation control unit is respectively connected with the second-stage circulating pool 1-20, the second-stage circulating pump 1-21 and the se...

Embodiment 3

[0138] For steel mill flue gas containing N 2 and part O 2 In addition, it contains about 5-8% water vapor, 15%-25% CO 2 and 2500~4000ppm SO 2 Wait.

[0139] The first-stage circulation control unit is respectively connected with the first-stage circulation tank 1-17, the rich liquid pump 1-18 and the first-stage circulating cooler 1-19, and controls the first-stage circulation independently. The first-stage circulation control unit controls the pH of the absorption liquid in the first-stage circulation tank 1-17, the flow rate of the rich liquid pump circulation 1-18 and the cooling water flow of the first-stage circulating cooler 1-19, so that the first-stage circulation pH is 4.5, and the circulating liquid-gas ratio is 2.0L / m 3 , the absorption temperature is 58 ℃.

[0140] The second-stage circulation control unit is respectively connected with the second-stage circulating pool 1-20, the second-stage circulating pump 1-21 and the second-stage circulating cooler 1-22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com