Ti-MOFs (at) COFs hybrid material with stable core-shell structure as well as preparation method and application of Ti-MOFs (at) COFs hybrid material

A hybrid material and shell structure technology, applied in the field of Ti-MOFs@COFs hybrid materials, the preparation of Ti-MOFs@COFs hybrid materials, and photocatalytic materials, to improve catalytic activity and product selectivity, and promote rapid migration , Improve the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Ti-MOFs@COFs hybrid material NH with core-shell structure 2 - Preparation of MIL-125@COF-OH-1:

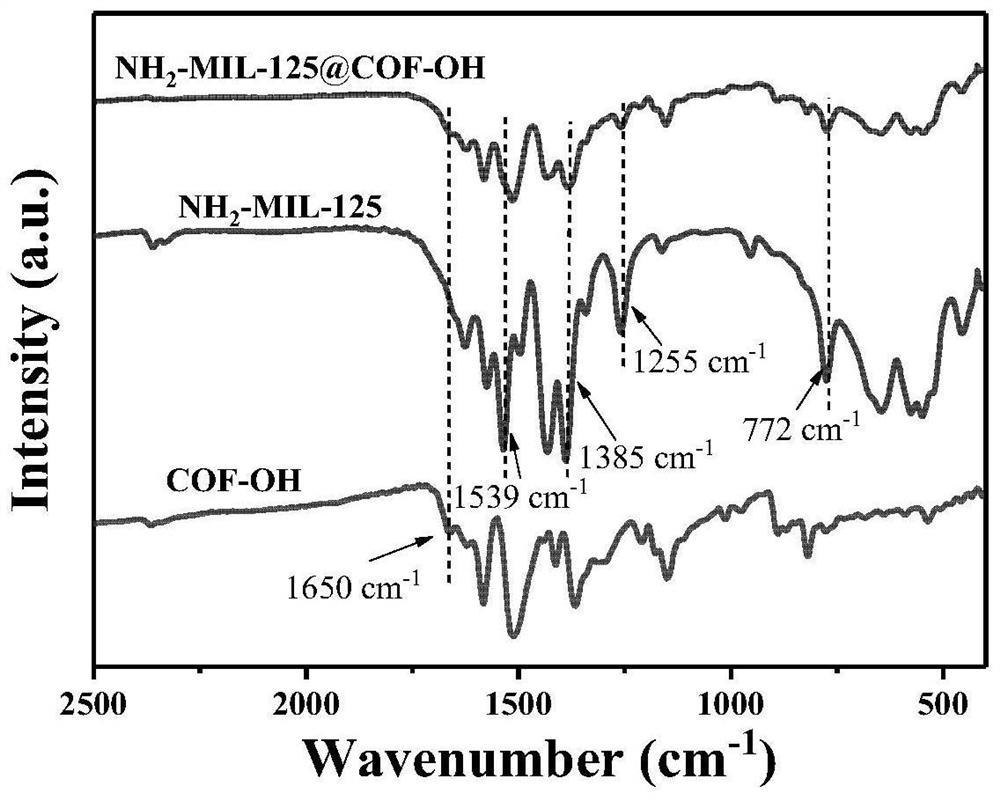

[0043] Dissolve 2,5-dihydroxyterephthalaldehyde (3 mmol) in 2 mL of acetonitrile by sonication and dissolve the NH 2 -MIL-125 (30 mg) was dispersed in the above-mentioned 2 mL of acetonitrile, and sonicated for 1.0 h to form a uniform suspension. 2,4,6-Tris(aminophenyl)-1,3,5-triazine (2 mmol) was dissolved in 2 mL of acetonitrile, slowly added dropwise to the above suspension, and sonicated for 1.0 h. Then add 0.5 mL of 12 mol / L acetic acid, and sonicate for 1 min. After three cycles of freezing-vacuum-thawing, the lids were sealed and left to react at room temperature for 72 h. Filtered with suction, washed repeatedly with methanol, ethanol, dichloromethane, and tetrahydrofuran, and extracted with methanol and tetrahydrofuran for Soxhlet for 24 h, dried at 120 °C for 12 h, and then vacuum-dried for 24 h to obtain a core-shell structure Ti-MOFs@COFs hybrid material . I...

Embodiment 2

[0046] Ti-MOFs@COFs hybrid material NH with core-shell structure 2 - Preparation of MIL-125@COF-OH-2:

[0047] Dissolve 2,5-dihydroxyterephthalaldehyde (3 mmol) in 2 mL of acetonitrile by sonication and dissolve the NH 2 -MIL-125 (20 mg) was dispersed in the above-mentioned 2 mL of acetonitrile, and sonicated for 1.0 h to form a uniform suspension. 2,4,6-Tris(aminophenyl)-1,3,5-triazine (2 mmol) was dissolved in 2 mL of acetonitrile, slowly added dropwise to the above suspension, and sonicated for 1.0 h. Then add 0.5 mL of 12 mol / L acetic acid, and sonicate for 1 min. After three cycles of freezing-vacuum-thawing, the lids were sealed and left to react at room temperature for 72 h. Filtered with suction, washed repeatedly with methanol, ethanol, dichloromethane, and tetrahydrofuran, extracted with methanol and tetrahydrofuran for 24 h, dried at 120 °C for 12 h, and then vacuum-dried for 24 h to obtain a core-shell structure Ti-MOFs@COFs hybrid material . Infrared characte...

Embodiment 3

[0050] Ti-MOFs@COFs hybrid material NH with core-shell structure 2 - Preparation of MIL-125@COF-OH-3:

[0051] Dissolve 2,5-dihydroxyterephthalaldehyde (3 mmol) in 2 mL of acetonitrile by sonication and dissolve the NH 2 -MIL-125 (10 mg) was dispersed in the above-mentioned 2 mL of acetonitrile, and sonicated for 1.0 h to form a uniform suspension. 2,4,6-Tris(aminophenyl)-1,3,5-triazine (2 mmol) was dissolved in 2 mL of acetonitrile, slowly added dropwise to the above suspension, and sonicated for 1.0 h. Then add 0.5 mL of 12 mol / L acetic acid, and sonicate for 1 min. After three cycles of freezing-vacuum-thawing, the lids were sealed and left to react at room temperature for 72 h. Filtered with suction, washed repeatedly with methanol, ethanol, dichloromethane, and tetrahydrofuran, and extracted with methanol and tetrahydrofuran for Soxhlet for 24 h, dried at 120 °C for 12 h, and then vacuum-dried for 24 h to obtain a core-shell structure Ti-MOFs@COFs hybrid material . I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com