Ultrahigh-temperature-resistant low-heat-conductivity magnesium-aluminum-chromium multivariate phosphate composite material and preparation method thereof

A technology of aluminum chromium phosphate and composite materials, which is applied in the field of thermal protection materials, can solve problems such as complex preparation process, complex composition, and limited high temperature resistance, and achieve simple preparation process, excellent comprehensive performance, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

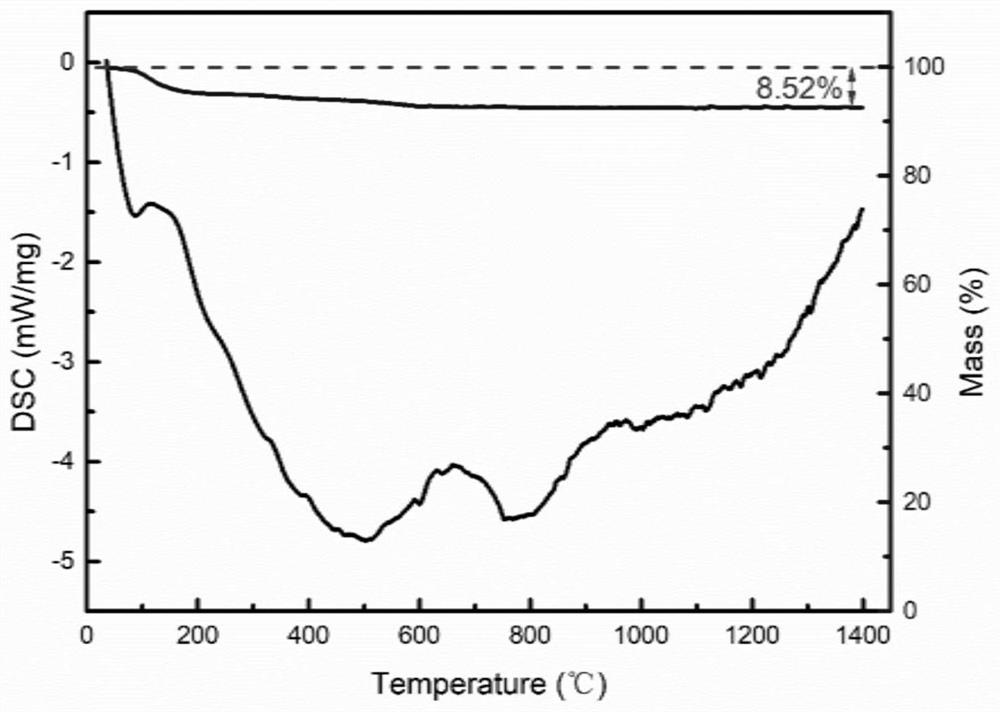

Embodiment 1

[0047] The 0.3mol / L aluminum phosphate solution and the 0.3mol / L chromium phosphate solution were heated and stirred in a constant temperature water bath at 90°C for 1 hour according to the volume ratio of 1:1, and the mixture was uniform. ·s of mixed phosphate solution. Then, deionized water was added to the mixed phosphate solution according to the mass ratio of 3:1, the temperature was maintained at 90 °C, and the aluminum-chromium phosphate solution with a viscosity of about 5 Pa·s was obtained after fully stirring for 1 h for dilution. Finally, MgO was weighed and mixed into the aluminum-chromium phosphate solution. Magnesium oxide was measured at 40% of the total mass of the composite material, and was continuously stirred at a rate of 3000 r / min for 20 minutes at room temperature until the color was light yellow, and then poured into the prepared In the mold, the aluminum-chromium-magnesium-based polyphosphate composite material was obtained after standing for 1 hour at...

Embodiment 2

[0056] The 0.3mol / L aluminum phosphate solution and the 0.3mol / L chromium phosphate solution were heated and stirred in a constant temperature water bath at 90°C for 1 hour according to the volume ratio of 1:1, and the mixture was uniform. ·s of mixed phosphate solution. Then, deionized water was added to the mixed phosphate solution at a mass ratio of 3:1, the temperature was maintained at 90 °C, and the solution was fully stirred for 1 h. After dilution, an aluminum-chromium phosphate solution with a viscosity of about 5 Pa·s was obtained. Finally, MgO was weighed and mixed into the aluminum-chromium phosphate solution. Magnesium oxide was measured at 50% of the total mass of the composite material, and was continuously stirred at a rate of 3000 r / min for 20 minutes at room temperature until the color was light yellow, and then poured into the prepared In the mold, the aluminum-chromium-magnesium-based polyphosphate composite material was obtained after standing for 1 hour a...

Embodiment 3

[0069] The 0.3mol / L aluminum phosphate solution and the 0.3mol / L chromium phosphate solution were heated and stirred in a constant temperature water bath at 90°C for 1 hour according to the volume ratio of 1:1, and the mixture was uniform. ·s of mixed phosphate solution. Then, deionized water was added to the mixed phosphate solution according to a mass ratio of 2:1, the temperature was maintained at 95 °C, and the mixture was fully stirred for 1 h. After dilution, an aluminum-chromium phosphate solution with a viscosity of about 3 Pa·s was obtained. Finally, MgO was weighed and mixed into the aluminum-chromium phosphate solution. Magnesium oxide was measured at 50% of the total mass of the composite material, and was continuously stirred at a rate of 3000 r / min for 20 minutes at room temperature until the color was light yellow, and then poured into the prepared In the mold, the aluminum-chromium-magnesium-based polyphosphate composite material was obtained after standing for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com