Tear-resistant and radiation-proof fabric and preparation method thereof

A radiation-proof and tear-resistant technology, applied in the field of fabrics, can solve the problems of heavy weight, human allergy, and unsatisfactory tear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

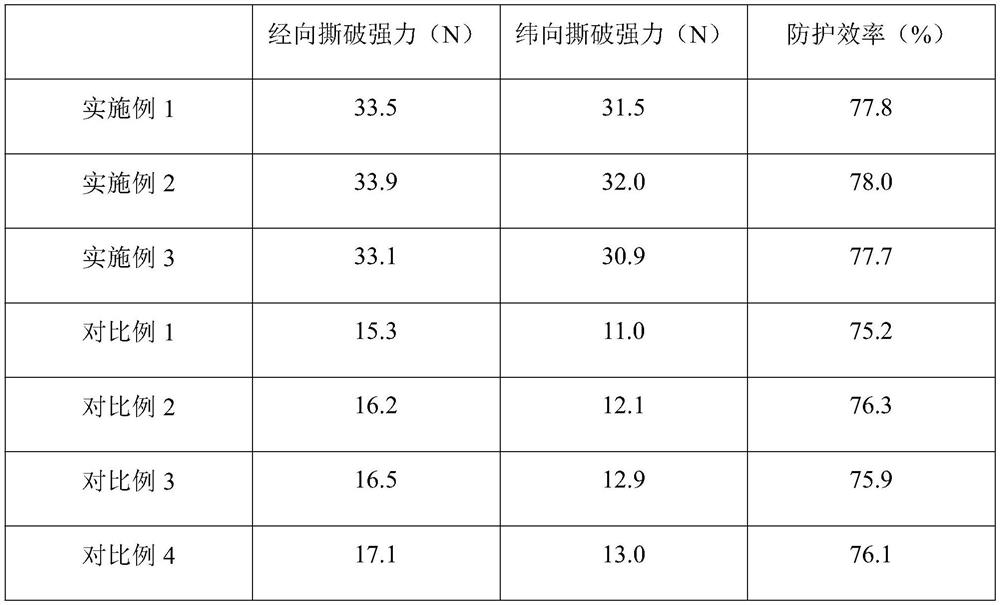

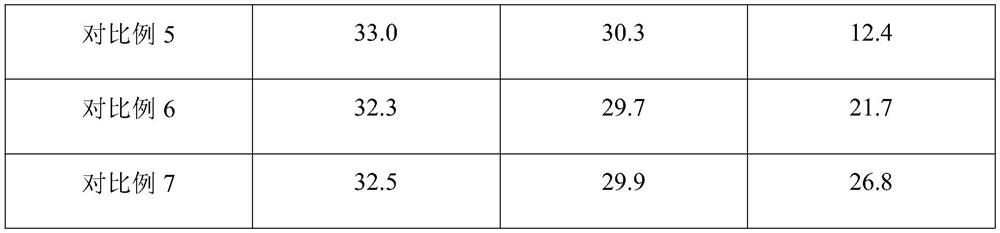

Examples

Embodiment 1

[0030] A preparation method of a tear-resistant radiation-proof fabric, the preparation method of the tear-resistant radiation-proof fabric mainly comprises the following preparation steps:

[0031] (1) soak the cotton fiber in sulfuric acid with a mass fraction of 2 times the mass of the cotton fiber, and after shaking at 25 kHz for 30 min, wash with distilled water until the pH of the solution is 6; and then soak in the mass fraction of 2 times the mass of the cotton fiber as 8% sodium hydroxide at a temperature of 86°C, soaked at a constant temperature for 70min, washed with distilled water for 3 times, and dried at 60°C for 3.5h to obtain pretreated cotton fibers; Dissolve ferric tetroxide in 90 times the mass of ferric tetroxide chloroform, then add hexadecyltrimethylammonium bromide solution with 650 times the mass of ferric oxide, cetyltrimethylammonium bromide and deionized hexadecyltrimethylammonium bromide solution The mass ratio of water is 1:50, heated to 50°C by wat...

Embodiment 2

[0038] A preparation method of a tear-resistant radiation-proof fabric, the preparation method of the tear-resistant radiation-proof fabric mainly comprises the following preparation steps:

[0039] (1) soak the cotton fiber in sulfuric acid with a mass fraction of 4 times the mass of the cotton fiber, and after shaking at 30 kHz for 23 min, wash with distilled water until the pH of the solution is 6.5; and then soak in the mass fraction of 4 times the mass of the cotton fiber as 8% sodium hydroxide at a temperature of 93 °C, soaked at a constant temperature for 62 minutes, washed with distilled water for 5 times, and dried at 65 °C for 2 hours to obtain pretreated cotton fibers; Chloroform, then add hexadecyltrimethylammonium bromide solution with 675 times the mass of ferric oxide, cetyltrimethylammonium bromide and deionized water in the hexadecyltrimethylammonium bromide solution The mass ratio is 1:50, heated to 55°C by water bath method, and after stirring at 80rpm for 1...

Embodiment 3

[0046] A preparation method of a tear-resistant radiation-proof fabric, the preparation method of the tear-resistant radiation-proof fabric mainly comprises the following preparation steps:

[0047] (1) soak the cotton fiber in sulfuric acid with a mass fraction of 6 times the mass of the cotton fiber, and after shaking at 35 kHz for 15 min, wash with distilled water until the pH of the solution is 7; and then soak in the mass fraction of 6 times the mass of the cotton fiber as 8% sodium hydroxide at a temperature of 100 ° C, soaked at a constant temperature for 55 minutes, washed with distilled water for 8 times, and dried at 70 ° C for 1.5 hours to obtain pretreated cotton fibers; Dissolve ferric tetroxide in 100 times the mass of ferric tetroxide chloroform, and then add hexadecyl trimethyl ammonium bromide solution with 700 times the mass of ferric oxide, hexadecyl trimethyl ammonium bromide and deionized hexadecyl trimethyl ammonium bromide solution The mass ratio of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com