Pipeline magnetic flux leakage detection device based on optical fiber coupling diamond-nitrogen vacancy color center

A technology of optical fiber coupling and magnetic flux leakage detection, which is applied in the direction of measuring devices, using optical devices, and using magneto-optical equipment for magnetic field measurement. It can solve the problems of temperature interference, low spatial resolution, and low sensitivity during the measurement process. Achieve the effects of fast transmission speed, high measurement sensitivity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

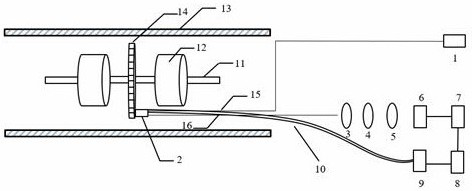

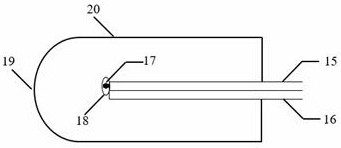

[0021] like figure 1 As shown, a pipeline magnetic flux leakage detection device based on fiber-coupled diamond-nitrogen vacancy color center, comprises a light generator 1, and it is characterized in that, the light generator 1 communicates with the magneto-optical conversion part 2 through the optical fiber A15, and the magneto-optical conversion part 2 It is fixed on the plastic disc 14; the magnet guide 11 runs through the plastic disc 14, and a permanent magnet 12 is fixed at each end; after the exit end of the fiber B16 pigtail is fixed, the convex lens A3 and the filter are placed in parallel and at the same height behind the fiber B16. Sheet 4, convex lens B5 and photoelectric conversion device 6; photoelectric conversion device 6 is connected with lock-in amplifier 7; connected, and the reference signal output port of the microwave generating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com