Preparation method of water dispersible granules containing pyraclostrobin and dimethomorph

A technology of pyraclostrobin and dimethomorph, which is applied in the field of pesticides, can solve the problems of reducing the content of pyraclostrobin and dimethomorph, the influence of the bactericidal effect of fungicides, and the inability to solve the problems, so as to shorten the disintegration time, shorten the wetting time, and improve the effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

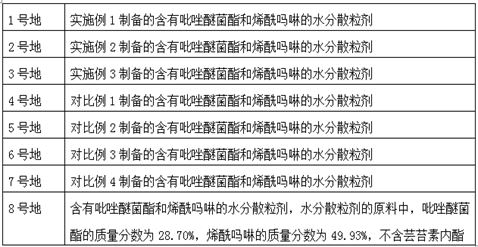

Embodiment 1

[0039] A preparation method of a water-dispersible granule containing pyraclostrobin and dimethomorph, specifically:

[0040] 1. Preparation of a mixture: add pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, diatomite after coupling modification, glucose, and brassinolide into the stirring tank Carry out stirring, control the rotating speed of the stirring tank to be 400 rpm, the temperature of the stirring tank to be 30 ° C, and the stirring time to be 40 min. After the stirring, jet pulverization is performed, and the pulverization temperature during the control jet pulverization is 20 ° C, and the pressure when entering the jet pulverizer is 1.5MPa, the pulverization pressure is 3MPa, the airflow velocity is 250m / s, the pulverization time is 1.2h, and the primary mixture is obtained after the airflow pulverization;

[0041] Wherein, the weight ratio of pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, diatomite after coup...

Embodiment 2

[0061] A preparation method of a water-dispersible granule containing pyraclostrobin and dimethomorph, specifically:

[0062] 1. Preparation of a mixture: add pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, coupled and modified diatomite, glucose, and uniconazole into the stirring tank for stirring , the rotating speed of the control stirring tank is 450rpm, the temperature of the stirring tank is 32 ℃, and the stirring time is 42min, and after the stirring, jet pulverization is carried out, and the pulverization temperature during the control jet pulverization is 22 ℃, and the pressure when entering the jet pulverizer is 1.6MPa , the crushing pressure is 3.2MPa, the airflow velocity is 270m / s, the crushing time is 1.3h, and the primary mixture is obtained after the airflow crushing;

[0063] Among them, the weight ratio of pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, diatomite after coupling modification, glucose and ...

Embodiment 3

[0083] A preparation method of a water-dispersible granule containing pyraclostrobin and dimethomorph, specifically:

[0084] 1. Preparation of a mixture: add pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, diatomite after coupling modification, glucose, and gibberellin into the stirring tank for stirring , the rotating speed of the control stirring tank is 500rpm, the temperature of the stirring tank is 35 ℃, and the stirring time is 45min. After the stirring, jet pulverization is carried out. , the crushing pressure is 3.5MPa, the airflow velocity is 280m / s, the crushing time is 1.5h, and the primary mixture is obtained after the airflow crushing;

[0085] Among them, the weight ratio of pyraclostrobin, tea saponin, calcium lignosulfonate, modified disintegrant, diatomite after coupling modification, glucose and gibberellin is 130:6:6:8 :15:8:4.4;

[0086] The preparation method of the modified disintegrant is as follows: placing sodium tripolyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com