Wide-temperature-range supercapacitor electrode material and device and preparation method

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, protection/regulation of hybrid/electric double-layer capacitors, etc., can solve the problem that there are few researches on bimetallic MOF-based electrode materials , to achieve good practicability, excellent electrochemical performance, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Surface cleaning and activation of carbon felt: A piece of 1cm×3cm commercial carbon felt was ultrasonically cleaned with 95% mass concentration ethanol solution and deionized water for 15min in turn; 2 SO 4 Solution with 3mol / LHNO 3 solution, and then measure 60mL and 20mL of the two in a volume ratio of 3:1 and pour them into a beaker filled with carbon felt; stir the beaker at a constant speed for 20min at room temperature, then transfer it to a 70°C water bath and continue to stir at a constant speed for 20min; After stirring, the carbon felt was taken out and washed three times with 95% mass concentration ethanol solution; finally, the carbon felt was placed in an oven at 65°C for drying for 5 hours, taken out, and weighed as M. 1 is 0.236g.

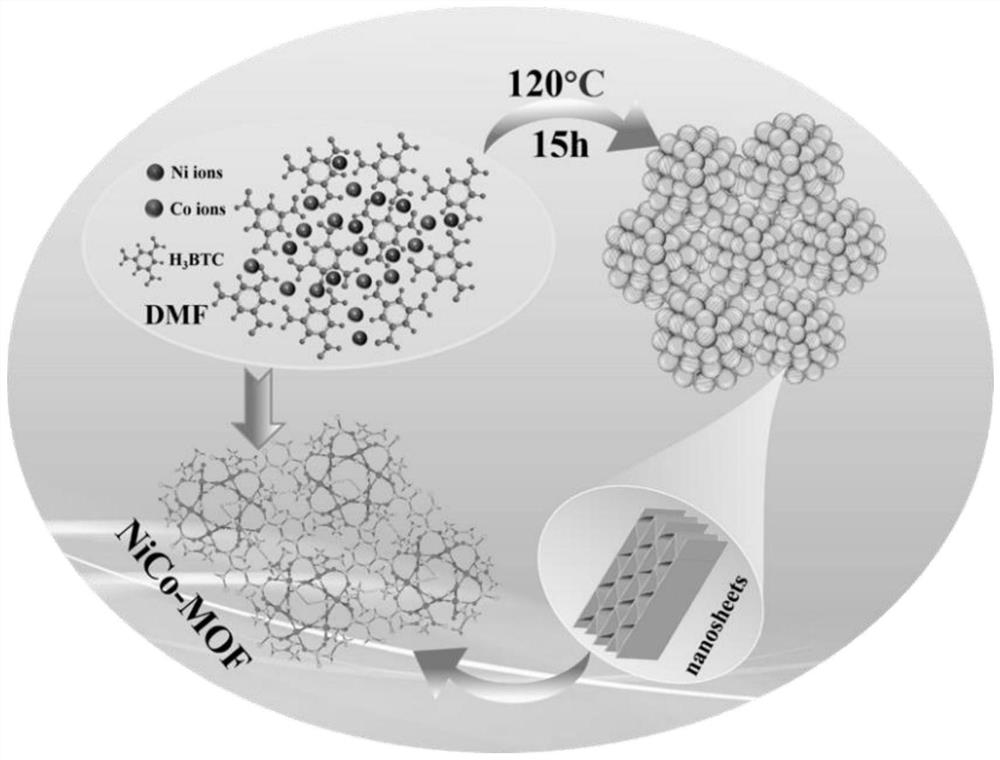

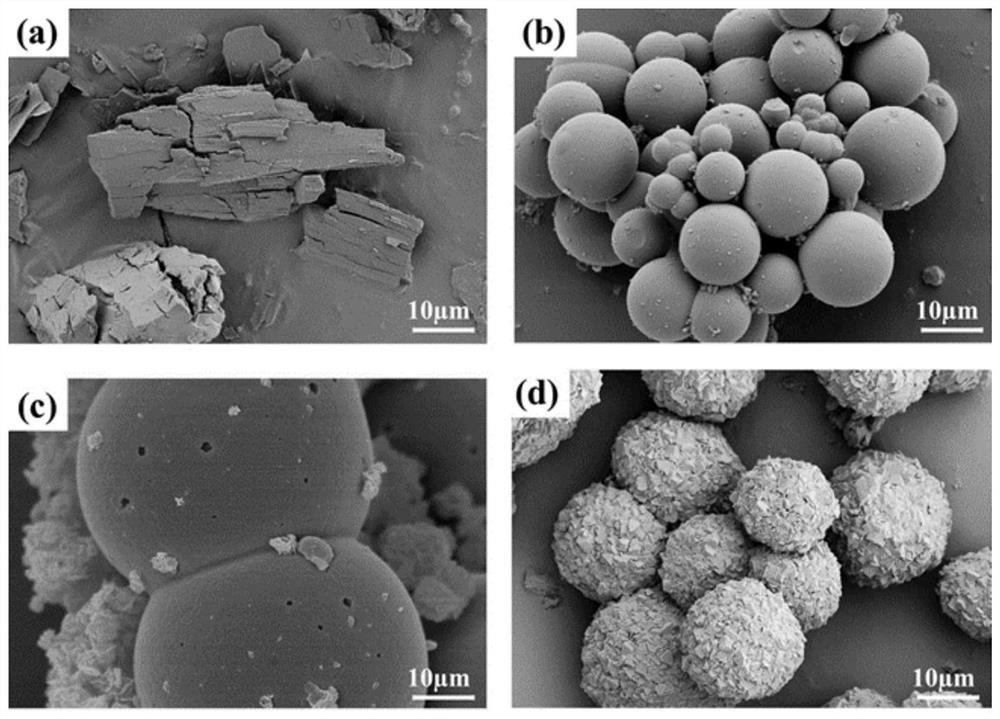

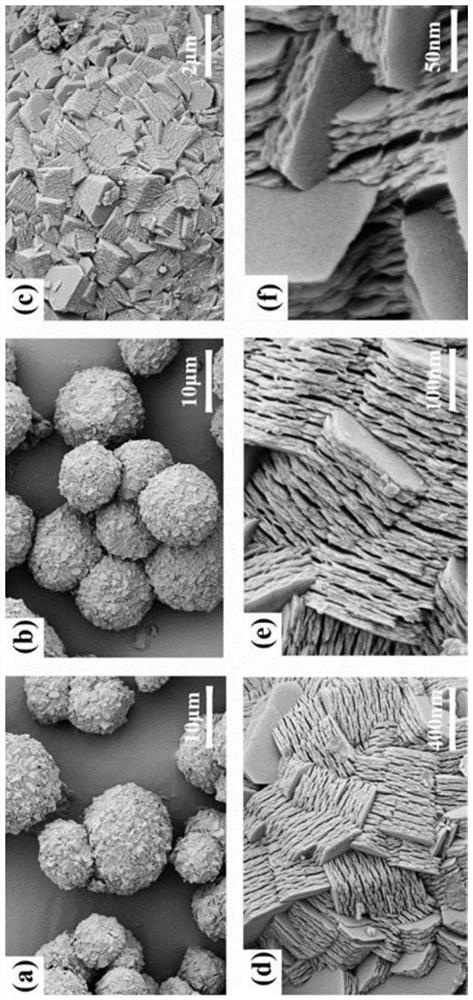

[0029] (2) Preparation of bimetallic NiCo-MOF cathode material: First, 1.5 mmol Ni(NO 3 ) 2 ·6H 2 O, 1.5 mmol Co(NO 3 ) 2 ·6H 2 O and 1.5 mmol H 3 BTC was dissolved in 60mL DMF solution, stirred at room temperatu...

Embodiment 2

[0033] (1) Cleaning and activation of carbon felt surface: this step is the same as that of Example 1, and its quality is called M 3 is 0.225g.

[0034] (2) Preparation of bimetallic NiCo-MOF cathode material: First, 1.5 mmol Ni(NO 3 ) 2 ·6H 2 O, 3 mmol Co(NO 3 ) 2 ·6H 2 O and 1.5 mmol H 3 BTC was dissolved in 60ml of DMF solution and stirred at room temperature for 10min at a speed of 900rpm / min; then, the mixed solution was transferred to a 100mL reactor, heated to 120°C at a rate of 5°C / min, and hydrothermally heated at this temperature. 15h; after the reaction is completed and naturally cooled to room temperature, the sample is placed in a centrifuge, and centrifuged at 10,000rpm / min for 3min; then rinsed 3 times with DMF, deionized water and 95% mass concentration ethanol solution in turn; finally, The obtained precipitate was placed in a drying oven and dried at 60 °C for 24 h. After drying, electrochemical tests were performed to obtain a specific capacitance of...

Embodiment 3

[0037] (1) Cleaning and activation of carbon felt surface: this step is the same as that of Example 1, and its quality is called M 5 is 0.215g.

[0038] (2) Preparation of bimetallic NiCo-MOF cathode material: First, 3 mmol Ni(NO 3 ) 2 ·6H 2 O, 1.5 mmol Co(NO 3 ) 2 ·6H 2 O and 1.5 mmol H 3 BTC was dissolved in 60ml of DMF solution and stirred at room temperature for 10min at a speed of 900rpm / min; then, the mixed solution was transferred to a 100mL reactor, heated to 120°C at a rate of 5°C / min, and hydrothermally heated at this temperature. 15h; after the reaction is completed and naturally cooled to room temperature, the sample is placed in a centrifuge, and centrifuged at 10,000rpm / min for 3min; then rinsed 3 times with DMF, deionized water and 95% mass concentration ethanol solution in turn; finally, The obtained precipitate was placed in a drying oven and dried at 60 °C for 24 h. After drying, electrochemical tests were performed to obtain a specific capacitance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com