Composite wire for grid, preparation method of composite wire, grid and lead-acid storage battery

A lead-acid battery, composite wire technology, applied in lead-acid battery, secondary battery repair/maintenance, electrode carrier/current collector, etc. The effect of low grid resistivity and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

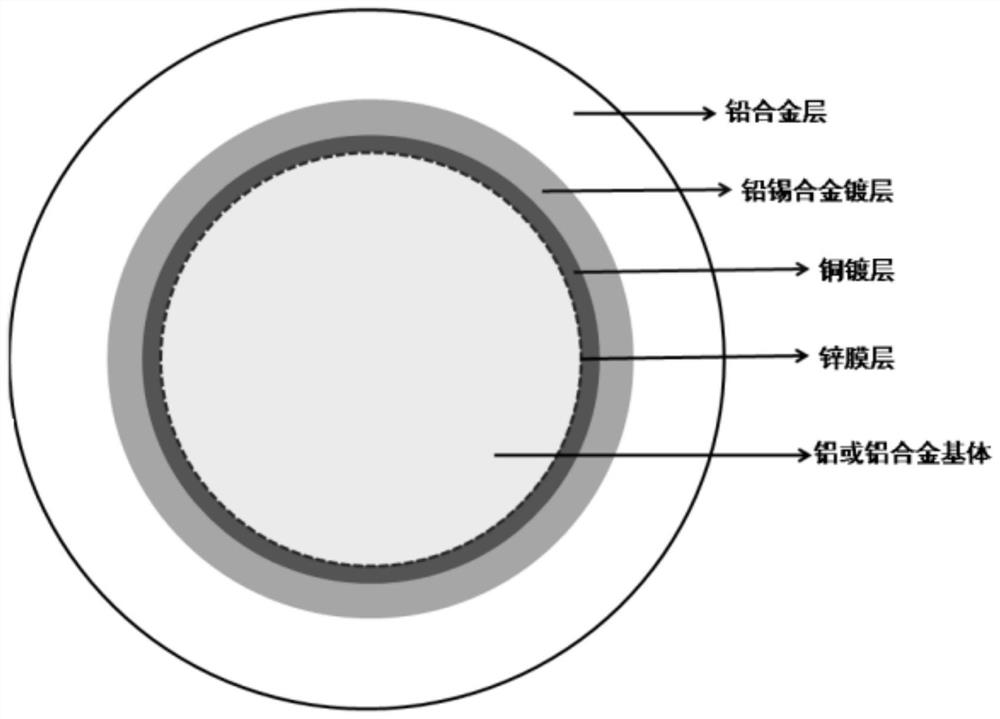

[0046] In a second aspect, the present invention also provides a method for preparing a composite wire for a grid, which is used for preparing the composite wire for a grid of the present invention, and the preparation method includes:

[0047] (1) placing the aluminum or aluminum alloy wire base in a zinc solution for zinc immersion treatment, and forming a zinc film layer on the surface of the aluminum or aluminum alloy wire base;

[0048] (2) placing the aluminum or aluminum alloy wire substrate with a zinc film layer on the surface to carry out copper plating treatment in a copper plating solution, and forming a copper plating layer on the surface of the zinc film layer;

[0049] (3) the aluminum or the aluminum alloy wire base that the surface contains zinc film layer, copper coating layer successively is placed in lead-tin plating solution and carries out lead-tin alloy plating process, and the lead-tin alloy coating layer is formed on the copper coating layer surface;

...

Embodiment 1

[0077] (1) The aluminum alloy wire base with a diameter of 0.8mm was degreasing in 22g / L NaOH, the temperature was 56 °C, and the wire base was washed with water after 58s of treatment; the washed wire base was immersed in a nitric acid solution with a mass fraction of 50% 58s, temperature 30℃, washed with deionized water;

[0078] (2) The aluminum alloy wire base body treated in step (1) is subjected to a zinc immersion treatment for 1.5 minutes at a temperature of 26 ° C. The zinc immersion solution formula is: NaOH 280g / L, ZnO 50g / L, potassium sodium tartrate 30g / L, FeCl 3 2.5g / L, KNO3 2.5g / L.

[0079] (3) Place the aluminum alloy wire after the first dipping in nitric acid solution for 28s to de-zinc, and wash the wire with deionized water for a second dipping treatment for 2min, and the temperature is controlled at 33°C;

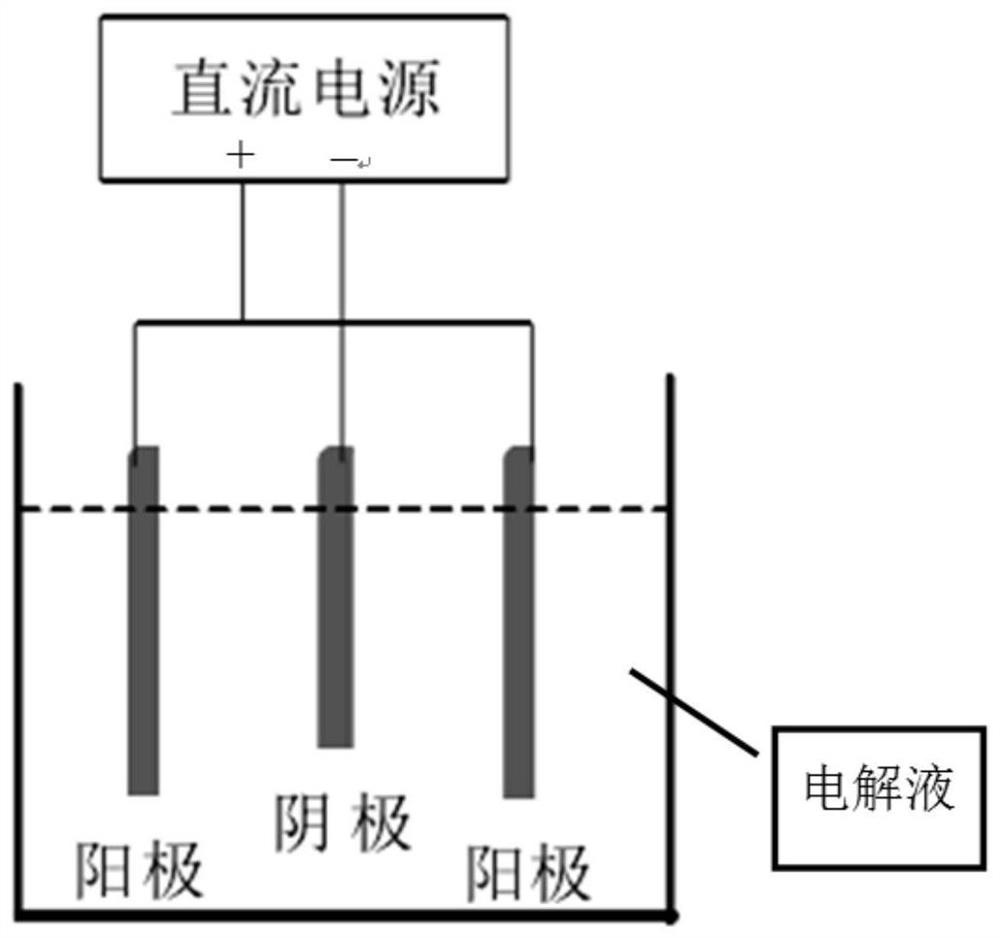

[0080] (4) place the aluminum alloy wire rod treated in step (3) in an alkaline copper plating solution, the red copper plate is the anode, and the...

Embodiment 2

[0085] (1) Degrease the aluminum alloy wire base with a diameter of 1.2 mm in 20g / L NaOH, at a temperature of 70 °C, and wash the wire base after 60s of treatment; the washed wire base is immersed in a nitric acid solution with a mass fraction of 50%. 60s, temperature 35℃, washed with deionized water;

[0086] (2) The aluminum alloy wire substrate treated in step (1) is subjected to a zinc immersion treatment for 3 minutes at a temperature of 34 ° C. The zinc immersion solution formula is: NaOH 300g / L, ZnO 55g / L, potassium sodium tartrate 35g / L, FeCl 3 3g / L, KNO 3 3g / L;

[0087] (3) Place the aluminum alloy wire after dipping in nitric acid solution for 30s to remove zinc, and wash the wire with deionized water for 2.5min, and control the temperature at 35°C;

[0088] (4) Place the aluminum alloy wire rod treated in step (3) in an alkaline copper plating solution, the red copper plate is the anode, and the current density is 1.5A / dm 2 , pH was controlled at 8, and washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com