Anti-single event effect radiation hardening band-gap reference circuit

An anti-single-event effect and radiation-hardening technology, which is applied in the direction of adjusting electrical variables, instruments, control/regulation systems, etc., can solve the problems of increased overall power consumption of the circuit, large voltage offsets of important nodes, and limited application range of the circuit, etc. , to achieve the effect of improving anti-SET performance, small area and power consumption, and expanding the scope of circuit applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

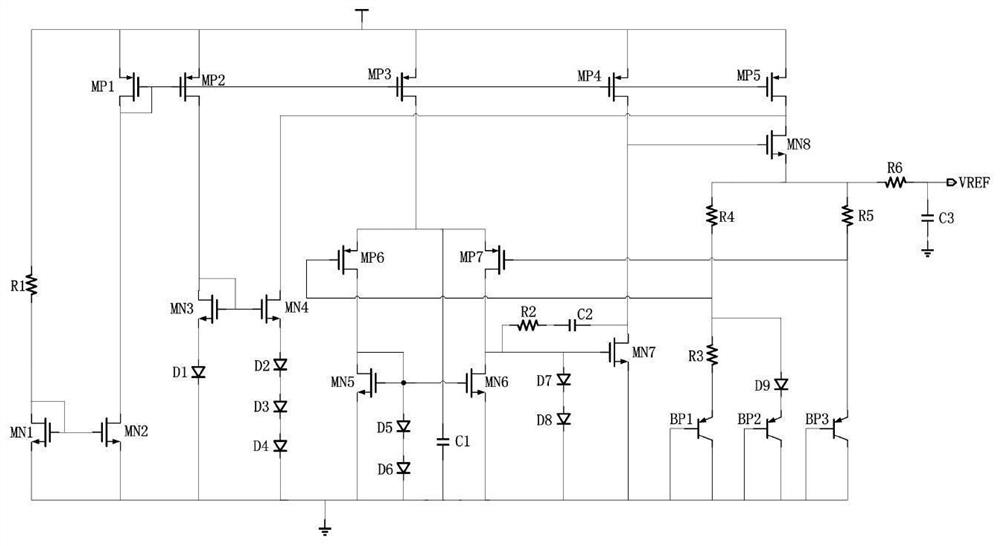

[0015] like figure 1 As shown, this embodiment provides an anti-single event effect radiation-hardened bandgap reference circuit, including PMOS transistors MP1-MP7; NMOS transistors MN1-MN8; diodes D1-D9; PNP transistors BP1-BP3; resistors R1-R6; C1 to C3.

[0016] R1, MN1, MN2, MP1, MP2, MN3, MN4, D1-D4 are startup circuits, and provide bias current to the entire bandgap reference circuit. After the circuit is started, the gate terminal voltage of MN3 is V D1 +V THN3 , the gate voltage required for MN4 to turn on is V D1 +V D2 +V D3 +V THN4 ≈3V D1 +V THN3 >V D1 +V THN3 , so the shutdown of MN4 after the startup is completed does not affect the normal operation of the reference circuit. At the same time, D1 can effectively discharge the transient current induced by the single particle incident at the drain terminal of MN3, and improve the anti-SET capability.

[0017] MP3, MP6, MP7, MN5, MN6, D5~D8, C1~C2, R2, MN7, MP4, MP5, MN8 constitute an operational amplifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com