Preparation method of longan pulp whole fruit powder rich in gamma-aminobutyric acid and composite fruit powder of longan pulp whole fruit powder

A technology of aminobutyric acid longan and longan pulp, which is applied in the fields of freezing/cold storage of fruits/vegetables, food science, etc. It can solve the problems of seasonal restrictions on longan production, inability to obtain whole fruit powder, and difficulty in obtaining whole fruit powder, etc., to achieve The effects of enriching varieties and markets, overcoming monotony of aroma and taste, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

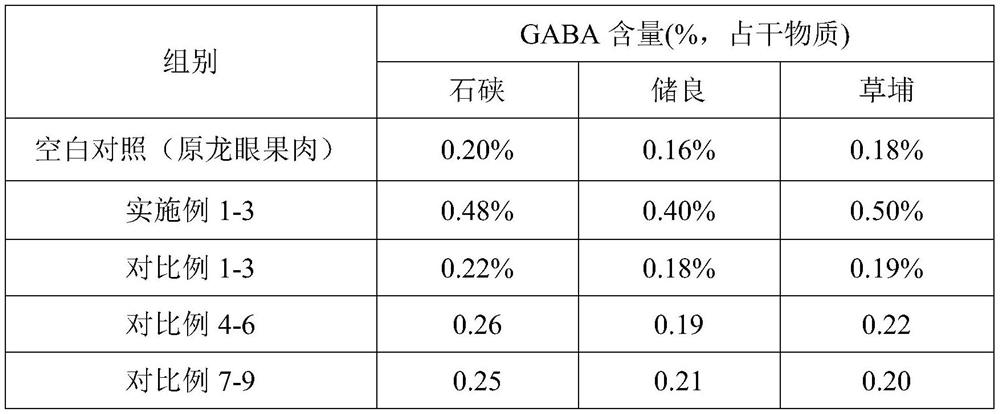

[0034] Embodiment 1 The preparation method of "Shi Kip" longan pulp whole fruit powder rich in GABA

[0035] In this embodiment, the longan variety "Shi Kip" is selected. First, the following pretreatment is performed, and 100 kg of fresh, mature, brightly colored, plump, non-worm-eaten and non-damaged longan fruits are selected and washed with soaking and spray equipment to remove the surface dirt on the longan shell. , microorganisms and residual pesticides, etc., drain the water; peel and take the pulp, manual peeling is done with stainless steel tongs or clip sleeves, and mechanical peeling is done by an automatic longan meat peeling machine; after testing the GABA quality of longan pulp The percentage content is 0.20%.

[0036] A preparation method of GABA-rich longan pulp whole fruit powder, the concrete steps are as follows:

[0037] S1. Longan pulp cutting treatment: cut the pretreated longan pulp into 1 / 2;

[0038] S2. Refrigeration treatment: the pulp after being c...

Embodiment 2

[0044] Example 2 Preparation of "Chuliang" longan pulp whole fruit powder rich in γ-aminobutyric acid

[0045] In this embodiment, the "Chuliang" longan variety is selected, and the following pretreatment is first performed, and 100kg of fresh, mature, brightly colored, plump, non-worm-eaten and non-damaged longan fruits are selected, and washed with soaking and spraying equipment to remove the dirt on the surface of the longan shell. , microorganisms and residual pesticides, etc., drain the water; peel and take the pulp, manual peeling is done with stainless steel tongs or clip sleeves, and mechanical peeling is done by an automatic longan meat peeling machine; after testing the GABA quality of longan pulp The percentage content is 0.16%.

[0046] A preparation method of GABA-rich longan pulp whole fruit powder, the concrete steps are as follows:

[0047] S1. Longan pulp cut processing: cut the pretreated longan pulp into 1 / 4;

[0048] S2. Refrigeration treatment: the pulp ...

Embodiment 3

[0054] Example 3 Preparation of "Caopu" longan pulp whole fruit powder rich in γ-aminobutyric acid

[0055] In this embodiment, the variety of "Caopu" longan is selected, firstly, the following pretreatment is performed, and 100 kg of fresh, mature, brightly colored, plump, non-worm-eaten and non-damaged longan fruits are selected, and washed with soaking and spraying equipment to remove the dirt on the surface of the longan shell. , microorganisms and residual pesticides, etc., drain the water; peel and take the pulp, manual peeling is done with stainless steel tongs or clip sleeves, and mechanical peeling is done by an automatic longan meat peeling machine; after testing the GABA quality of longan pulp The percentage content is 0.18%.

[0056] A preparation method of GABA-rich longan pulp whole fruit powder, the concrete steps are as follows:

[0057] S1. Longan pulp cut processing: cut the pretreated longan pulp into 1 / 8;

[0058] S2. Refrigeration treatment: the pulp aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com