Method and system for efficiently utilizing methane-rich gas

A methane-enriched, methane-steam technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as difficult to popularize carbon dioxide capture, flooding and storage, reduce long-distance transportation costs and ensure production , low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

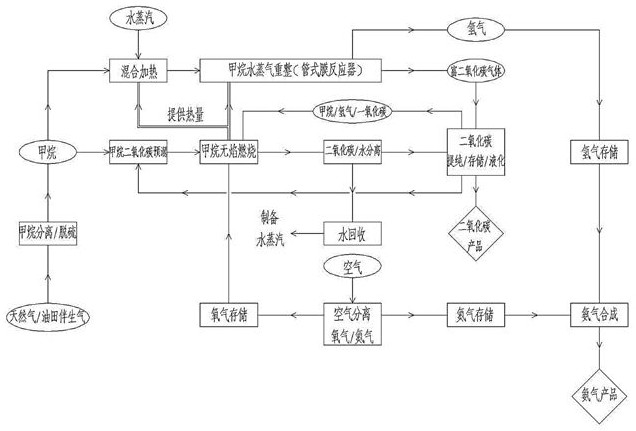

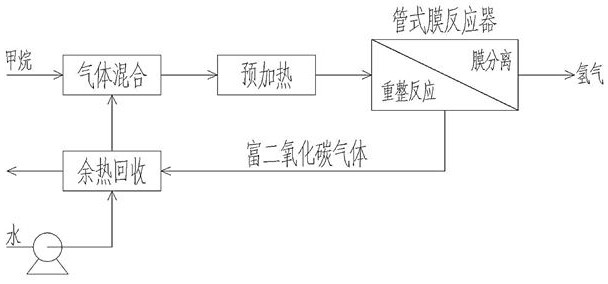

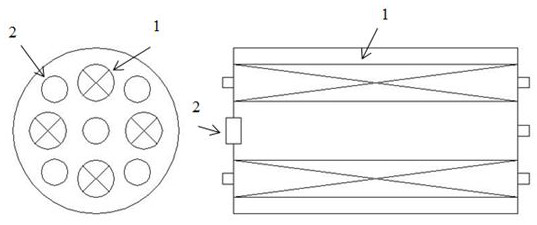

[0056] like figure 1 and 2 As shown, the embodiment of the present invention provides a method for efficient utilization of methane-rich gas, as a typical but not limited optional implementation method, which includes the following steps:

[0057] (1) Methane CH 4 After pretreatment such as separation / desulfurization, it enters the mixer and is fully mixed with water vapor to form a mixed gas. The molar ratio of water to carbon is CH 4 : H 2O=1:3~5. The mixed gas enters the pre-heater and is heated to about 550~600 ℃, and then the mixed gas enters the methane steam reforming reactor. Under the catalysis of nickel-based catalyst, the reaction temperature is controlled at 600~750℃, and the reaction pressure is 0.5MPa~2MPa. The mixed gas undergoes a reforming reaction to form carbon dioxide CO 2 , carbon monoxide CO, hydrogen H 2 .

[0058] (2) CH 4 After pretreatment such as separation / desulfurization, it is first mixed with CO 2 Gas premix. The mixed gas exchanges h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com