Organic silicon modified polymeric nonionic surfactant and preparation method thereof

A non-ionic surface and silicone technology, which is applied in the field of polymeric non-ionic surfactants and their preparation, can solve the problems of difficult effective association structure of surfactants, unsatisfactory emulsification and dispersion, and easy foaming, etc. problems, to achieve the effect of easy control of structure, small molecular weight and good foam suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A first aspect of the present invention provides a preparation method of an organosilicon-modified polymeric nonionic surfactant, the method comprising the following steps:

[0046] (1) Preparation of raw materials: the raw materials include isocyanate, aliphatic alcohol polyoxyethylene ether, terminal bishydroxyhydrocarbyl polysiloxane, catalyst and solvent;

[0047] Described isocyanate is hexamethylene diisocyanate trimer;

[0048] Described fatty alcohol polyoxyethylene ether is AEO series fatty alcohol polyoxyethylene ether, JFC series fatty alcohol polyoxyethylene ether or Periplus series fatty alcohol polyoxyethylene ether;

[0049] The molecular weight of the terminal dihydroxy hydrocarbon polysiloxane is 1000-2000;

[0050] The molar fraction of each component in the raw material is: 1.0 isocyanate, 2.5-3.0 fatty alcohol polyoxyethylene ether, 0.1-0.3 bishydroxyl-terminated hydrocarbyl polysiloxane; wherein, the molar fraction of dihydroxyl-terminated hydrocar...

Embodiment 1

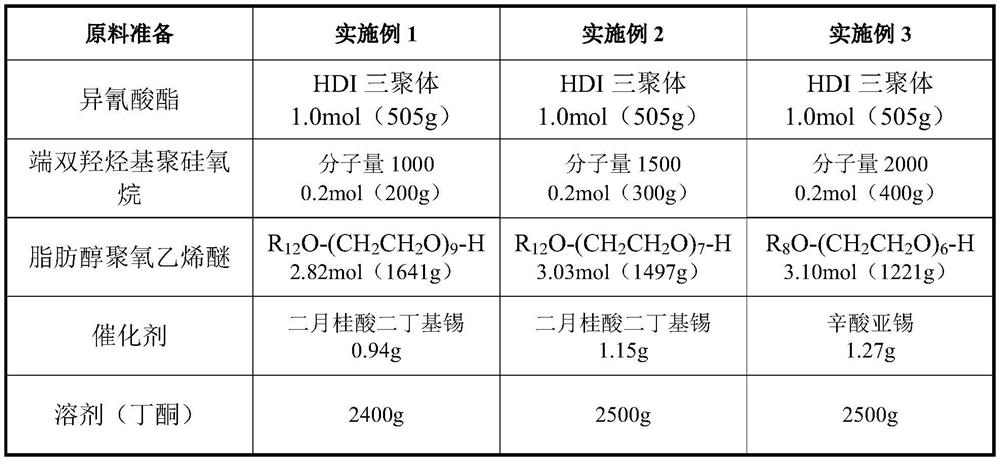

[0074] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0075] (2) Polymerization: carry out polymerization reaction of isocyanate with terminal bishydroxyhydrocarbyl polysiloxane, aliphatic alcohol polyoxyethylene ether, catalyst and solvent to obtain an organosilicon-modified polymeric nonionic surfactant solution;

[0076] (2.1) adding fatty alcohol polyoxyethylene ether into the reactor, dehydrating in vacuum at 105°C for 90min, cooling to 67°C, for subsequent use;

[0077] (2.2) under stirring, successively add solvent, terminal bishydroxyhydrocarbyl polysiloxane, isocyanate and catalyst to another reactor, after mixing evenly, gradually heat up to 75°C in 30min, react for 50min, cool down to 72°C, set aside for later use ;

[0078] (2.3) under stirring, the material in (2.1) is added to the reaction system in (2.2), and the reaction temperature is controlled to be 75° C. for 90 min to obtain a poly...

Embodiment 2

[0083] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0084] (2) Polymerization: carry out polymerization reaction of isocyanate with terminal bishydroxyhydrocarbyl polysiloxane, aliphatic alcohol polyoxyethylene ether, catalyst and solvent to obtain an organosilicon-modified polymeric nonionic surfactant solution;

[0085] (2.1) adding fatty alcohol polyoxyethylene ether into the reactor, dehydrating in vacuum at 105°C for 90min, cooling to 66°C, for subsequent use;

[0086](2.2) under stirring, successively add solvent, terminal bishydroxyhydrocarbyl polysiloxane, isocyanate and catalyst into another reactor, after mixing evenly, gradually heat up to 80°C in 20min, react for 50min, cool down to 77°C, set aside for later use ;

[0087] (2.3) under stirring, the material in (2.1) was added to the reaction system in (2.2), and the reaction temperature was controlled to be 80° C. for 100 min to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com