Composite wafer protective film and preparation method thereof

A technology of composite crystal and protective film, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesives, adhesives, etc. Protective film adhesion and other issues, to reduce redundant processes, not easy to heat shrink, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

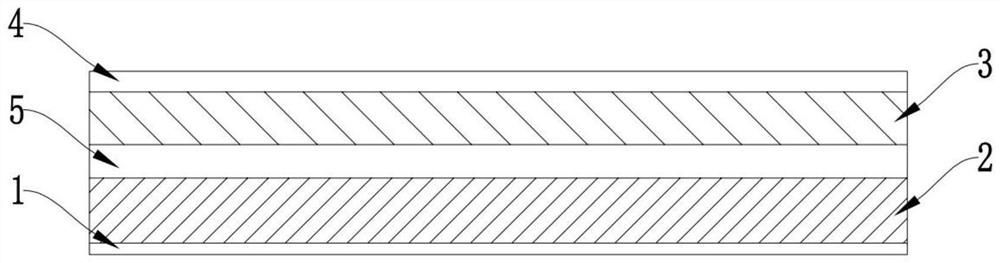

[0056] A preparation method of a composite wafer protective film, used for preparing the above-mentioned composite wafer protective film, comprises the following steps:

[0057] A. The polyvinyl chloride film is used as the polyvinyl chloride layer 2, and a UV release agent is coated on any side of the polyvinyl chloride layer 2, and a release layer 1 is formed after UV irradiation and curing, and a release layer 1 and polyvinyl chloride are obtained. the first composite layer of vinyl layer 2;

[0058] B, the raw material of thermoplastic polyurethane elastomer layer 3 is extruded and compounded by means of co-extrusion casting to obtain thermoplastic polyurethane elastomer layer 3;

[0059] C, prepare the pressure-sensitive adhesive solution, coat the pressure-sensitive adhesive solution on the surface of the thermoplastic polyurethane elastomer layer 3 of step B, and obtain the second composite layer with the thermoplastic polyurethane elastomer layer 3 and the pressure-sen...

Embodiment 1

[0077] Embodiment 1-a kind of preparation method of composite wafer protective film

[0078] A. Use a polyvinyl chloride film with a thickness of 20 μm, a tensile strength of 20 MPa and an elongation at break of 250% as the polyvinyl chloride layer, apply UV release agent on any side of the polyvinyl chloride layer, and use a high-pressure mercury lamp. After the UV release agent is cured by UV irradiation, a release layer with a thickness of 0.5 μm and a release force of 4gf / 25mm is formed to obtain a first composite layer with a release layer and a polyvinyl chloride layer; wherein, the strength of the curing step is is 100W / cm, and the energy density is 400mJ / cm 2 ;

[0079] B. The polyester thermoplastic polyurethane elastomer is extruded and compounded by co-extrusion casting to obtain a thermoplastic polyurethane elastomer layer with a thickness of 5 μm, a tensile strength of 20 MPa and an elongation at break of 250%;

[0080] C, prepare the pressure-sensitive adhesive...

Embodiment 2

[0082] Embodiment 2-a kind of preparation method of composite wafer protective film

[0083] A. A polyvinyl chloride film with a thickness of 100 μm, a tensile strength of 25 MPa and an elongation at break of 280% is used as the polyvinyl chloride layer, and UV release agent is coated on any side of the polyvinyl chloride layer, and a high-pressure mercury lamp is used. After the UV release agent is cured by UV irradiation, a release layer with a thickness of 1.5 μm and a release force of 3gf / 25mm is formed to obtain a first composite layer with a release layer and a polyvinyl chloride layer; wherein, the strength of the curing step is is 140W / cm, and the energy density is 700mJ / cm 2 ;

[0084] B. The polyether thermoplastic polyurethane elastomer is extruded and compounded by co-extrusion casting to obtain a thermoplastic polyurethane elastomer layer with a thickness of 25 μm, a tensile strength of 25 MPa and an elongation at break of 280%;

[0085] C, prepare a pressure-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com