Method for testing SEM and TEM by collecting fine particulate matters through TGDSC

A technology for fine particles and samples, applied in particle and sedimentation analysis, weighing by removing certain components, measuring devices, etc., can solve problems such as difficult fine particle emission modes and fine particles that do not directly correspond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

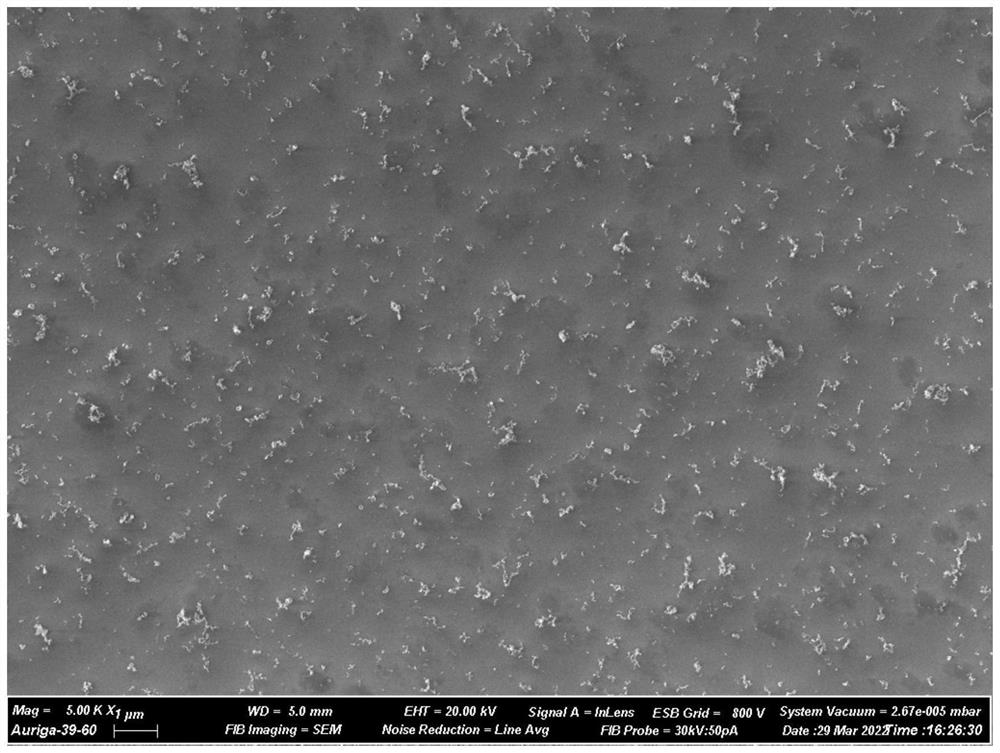

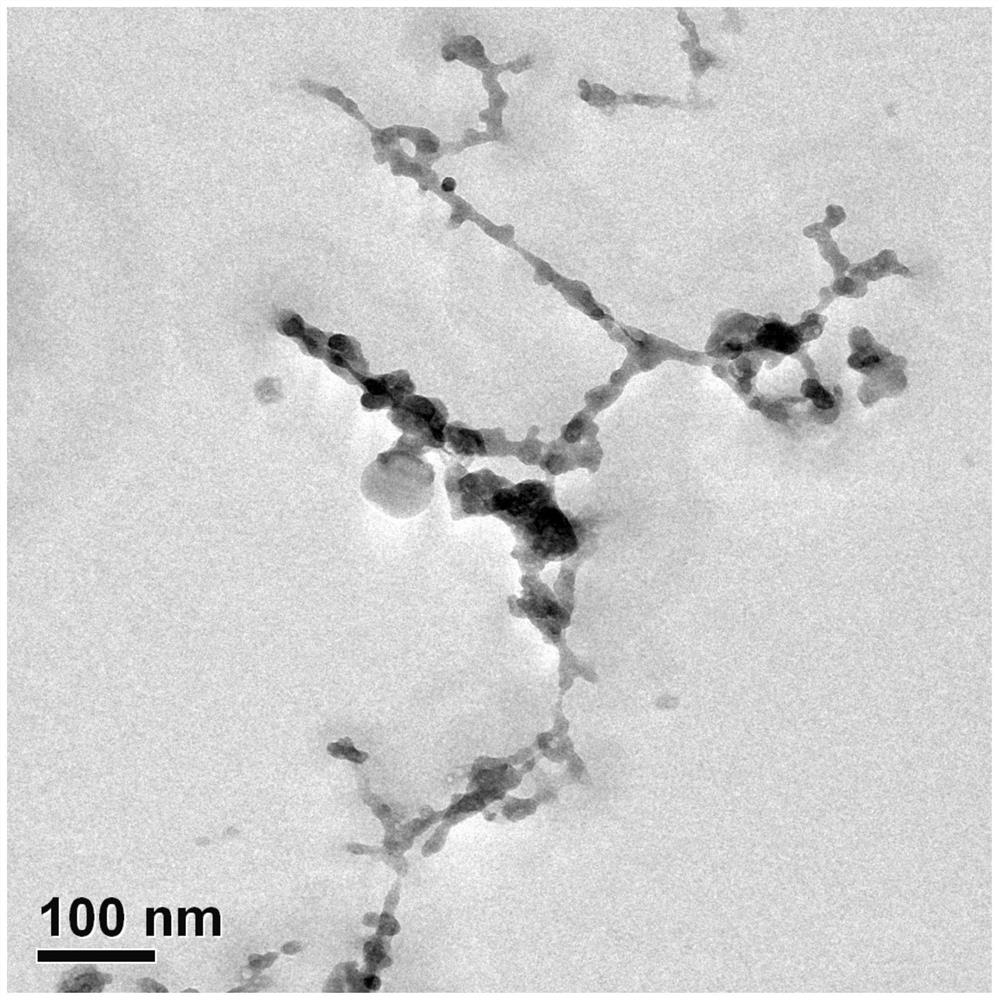

[0040] A method for testing SEM and TEM by collecting fine particles by TGDSC, by installing a gas sampling clip containing a gas filter membrane on the pipe at the gas outlet of the TGDSC instrument, and then passing a single crystal silicon wafer and a copper mesh with a carbon membrane through both sides The glue is fixed on the filter membrane; with the start of the TGDSC experiment, when the heating temperature reaches the combustion temperature, decomposition temperature or melting temperature of the sample, the sample will escape gas and fine particles to the surrounding, and the generated escape gas and fine particles will The carrier gas for thermal analysis is brought into the thermal analysis outlet pipe and passes through the gas sampling clip. Since the size of the fine particles generated by the sample is larger than the size of the gas molecules, the fine particles cannot penetrate the filter membrane and pass through the gas sampling clip, and will be deposited o...

Embodiment 2

[0042] A method of collecting fine particles by TGDSC to test SEM and TEM, thermal analysis (TGDSC) experiments can be continuously fed with argon, nitrogen or air and other gases, and the heating rate can be changed to obtain a series of physical phenomena that occur in the sample as the temperature changes. Chemical reactions, the research methods of TGDSC cover almost all kinds of carbon materials, polymers, metals, and silicate materials. When the sample is heated to a certain temperature, the sample will undergo combustion and decomposition reactions, resulting in weight loss of the sample. The weight loss is due to the reaction process. Gas will escape from the original sample, and with the escape of gas, it will take away a large number of particles with different particle sizes. The composition of the gas is detected to determine what gas will be generated during the heating process of the sample, so as to grasp the high-temperature reaction mechanism of the sample. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com