Purification method of high-purity tungsten hexacarbonyl

A technology of tungsten hexacarbonyl and purification method, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of cumbersome, no vacuum connection, unattainable purity, etc., and achieves simple operation, less labor, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

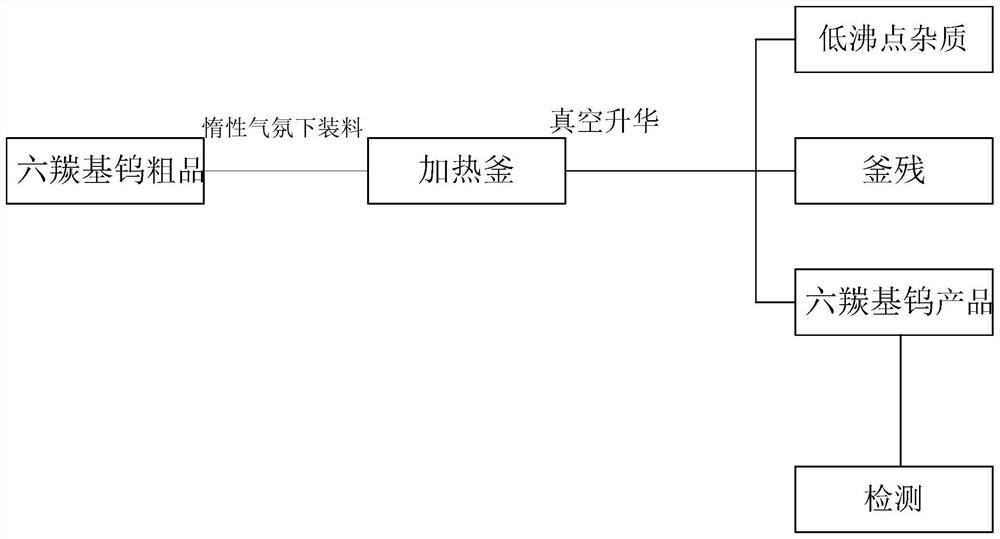

Method used

Image

Examples

Embodiment

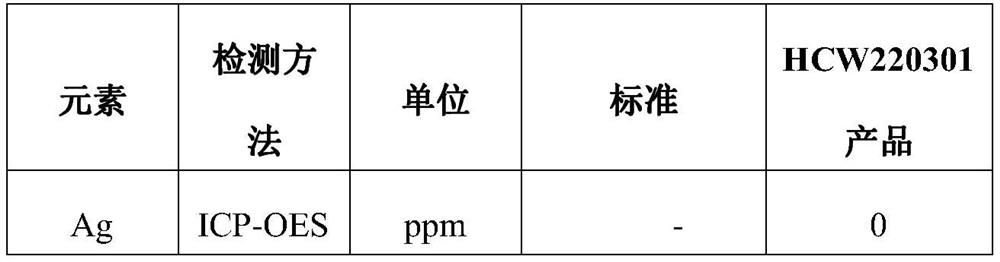

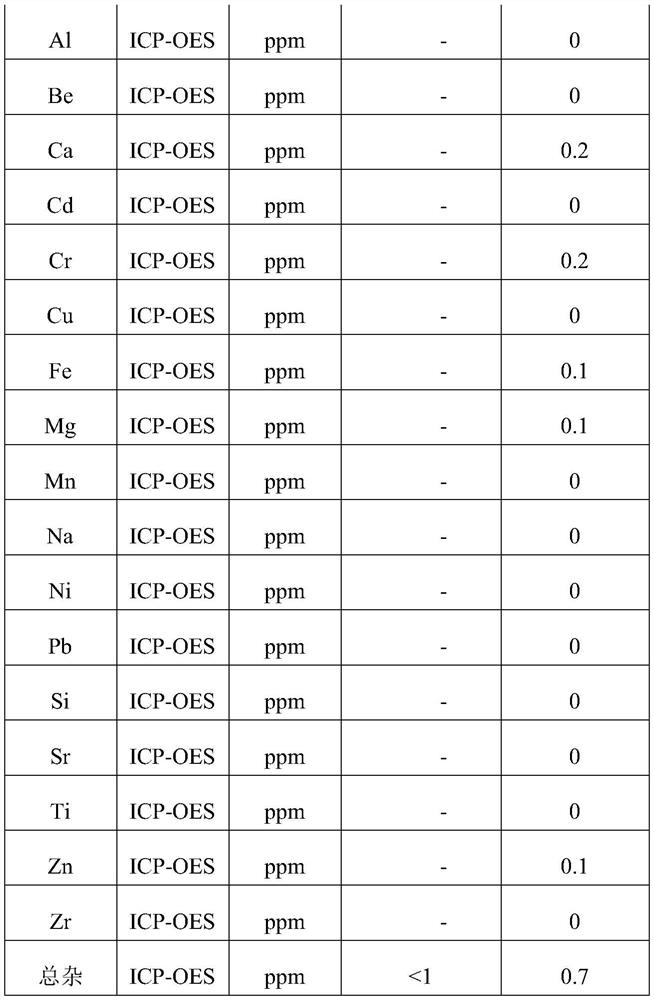

[0029] The AR grade of tungsten hexacarbonyl was selected, and the effective content of tungsten hexacarbonyl in the raw material was 99% and the moisture content was 5ppm after ICP-OES detection.

[0030] Take 90 g of tungsten hexacarbonyl and put it into a flask, seal the flask and put it into a vacuum oven, carry out suction drying, transfer it to an inert gas glove box without water and oxygen, and let it stand. Because the product is required to be anhydrous, after NMR sampling, the content of water has been reduced to less than 1ppm, and it was not detected.

[0031] In an inert gas glove box, pour tungsten hexacarbonyl into an eggplant-shaped bottle, connect a 90° elbow to the receiving bottle, and connect to cold hydrazine for vacuum operation. When the vacuum drops to about 1.35KPa, turn on the heating of the sublimation column, then turn on the heating of the kettle and the heating of the receiving bottle, when the heating temperature of the kettle reaches 50 °C, clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com