Light-emitting auxiliary material and preparation method thereof, light-emitting device and light-emitting device

A technology of auxiliary materials and light-emitting devices, applied in the field of materials, can solve the problems of insignificant improvement of lifespan and luminous efficiency, and achieve the effect of high hole transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] There is no limitation on the preparation method of the light-emitting device in this application, and conventional methods in the field are sufficient. In this application, methods such as thin film evaporation, electron beam evaporation or physical vapor deposition are preferably used to evaporate metals and conductive oxides on the substrate. and their alloys to form an anode, and then an organic layer and an evaporation cathode are formed thereon to obtain a light-emitting device.

[0061] The light-emitting device provided in this application can be applied to an organic light-emitting device (OLED), an organic solar cell (OSC), an electronic paper (e-paper), an organic photoreceptor (OPC) or an organic thin film transistor (OTFT).

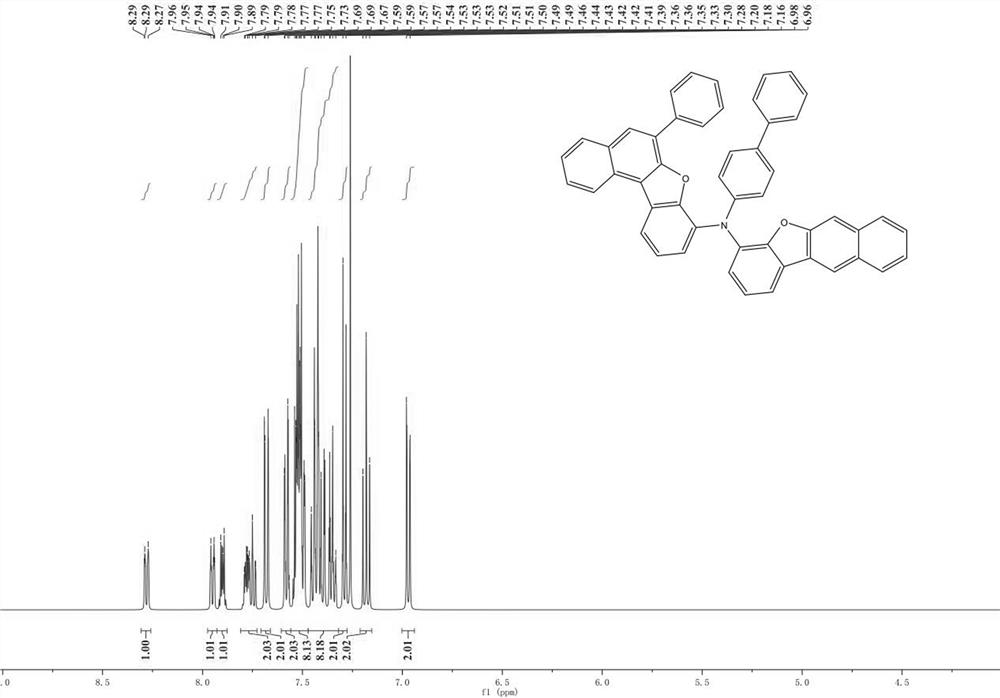

Embodiment 1

[0065]

[0066] After dissolving raw material A-1 (30.00 mmol) and raw material B-1 (30.00 mmol) in toluene, under N 2 Add Pd to the atmosphere 2 (dba) 3 (0.30mmol), P(t-Bu) 3 (1.50 mmol) and t-BuONa (60.00 mmol), heated to 100 °C and stirred for 8 h. After the reaction was completed, use diatomaceous earth to filter while hot to remove salt and catalyst. After the filtrate was cooled to room temperature, distilled water was added to the filtrate. Washing was carried out in , the organic phase was retained after separation, the aqueous phase was extracted with ethyl acetate, and the combined organic layers were then dried using magnesium sulfate, and the solvent was removed using a rotary evaporator. Using a mixed solution of dichloromethane and petroleum ether (V:V=10:4), the remaining material was purified by column chromatography to obtain Intermediate 1 (10.57g, yield: 76.3%);

[0067] After dissolving intermediate 1 (21.67 mmol) and starting material C-I-1 (21.67 mm...

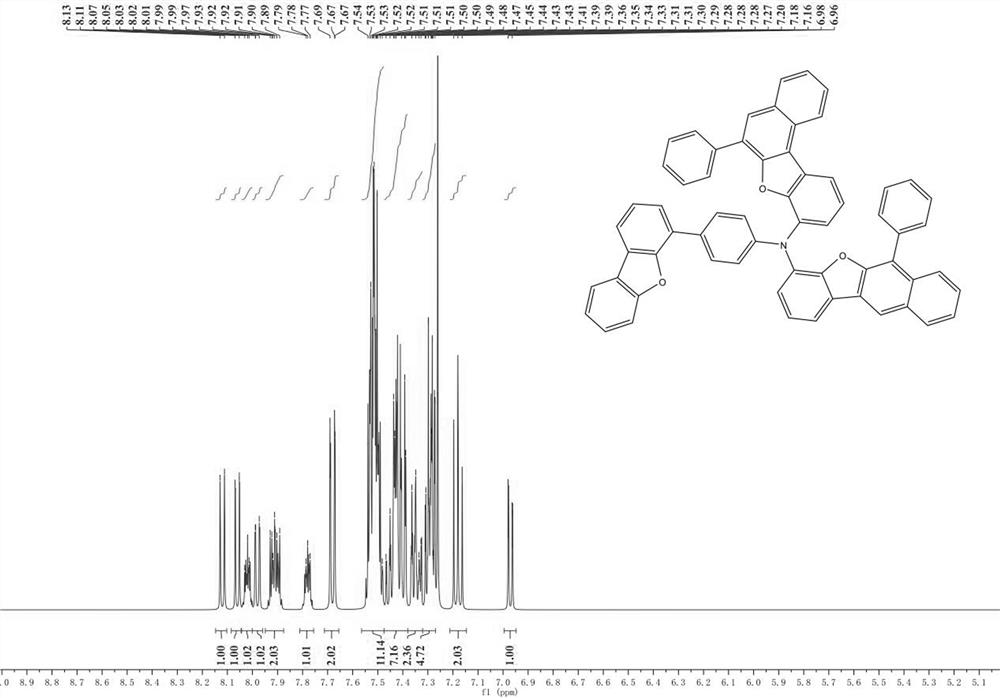

Embodiment 2

[0076]

[0077] After dissolving raw material A-27 (30.00 mmol) and raw material B-27 (30.00 mmol) in toluene, under N 2 Add Pd to the atmosphere 2 (dba) 3 (0.30mmol), P(t-Bu) 3 (1.50 mmol) and t-BuONa (60.00 mmol), heated to 100 °C and stirred for 8 h. After the reaction was completed, use diatomaceous earth to filter while hot to remove salt and catalyst. After the filtrate was cooled to room temperature, distilled water was added to the filtrate. Washing was carried out in , the organic phase was retained after separation, the aqueous phase was extracted with ethyl acetate, and the combined organic layers were then dried using magnesium sulfate, and the solvent was removed using a rotary evaporator. Using a mixed solution of dichloromethane and petroleum ether (V:V=10:4), the remaining material was purified by column chromatography to obtain Intermediate 1 (12.41 g, yield: 75.0%);

[0078] After dissolving intermediate 1 (21.75 mmol) and starting material C-I-27 (21.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com