Preparation method of viscosity reduction type polycarboxylate superplasticizer

A technology of viscous polycarboxylic acid and water reducing agent is applied in the field of preparation of viscosity reducing polycarboxylate water reducing agent. , the effect of reducing the thickness and reducing the surface tension of the liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

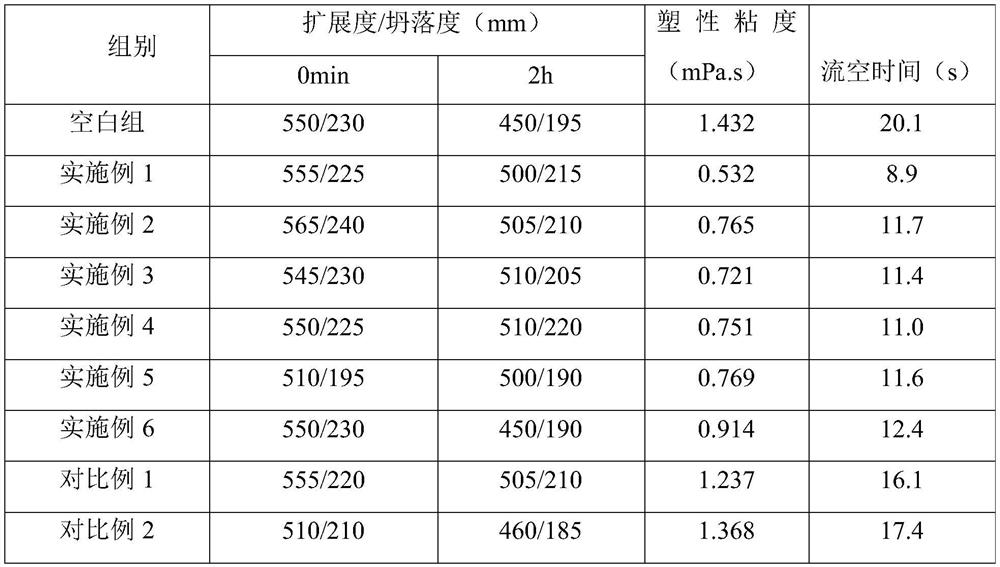

Examples

Embodiment 1

[0028] The present embodiment provides a preparation method of a viscosity-reducing polycarboxylate water-reducing agent, comprising the following steps:

[0029] S1. Add 200g of water to the four-necked flask, then add 240g of ethylene glycol monovinyl polyglycol ether (molecular weight 2400), 14g of vinyl trifluoroacetate and 1.2g of sp-80, fully dissolve to form an aqueous system ; Dissolve 1.2g vitamin C and 2.4g mercaptopropionic acid in 30g water to obtain liquid A; dissolve 21.6g acrylic acid and 15.5g cetyl methacrylate in 30g water to obtain liquid B;

[0030] S2. Add 4.8g TiO2 to the four-necked flask, then put it into the photoreactor, turn on the high-pressure mercury lamp after 30 minutes to irradiate it and time it, and irradiate it for 2-4h; Add solution A and solution B dropwise, wherein the dropwise addition time of solution A is 5h, and the dropwise addition time of solution B is 4h; after the dropwise addition, the reaction is incubated at 60-80°C for 10h, a...

Embodiment 2

[0033] The present embodiment provides a preparation method of a viscosity-reducing polycarboxylate water-reducing agent, comprising the following steps:

[0034] S1. Add 200g of water to the four-necked flask, then add 240g of ethylene glycol monovinyl polyglycol ether, 14g of vinyl trifluoroacetate and 2.4g of op-10, fully dissolve to form an aqueous system; add 2.4g of The hanging white block and 2.4g of mercaptoethanol were dissolved in 30g of water to obtain liquid A; 58g of hydroxyethyl acrylate and 14.2g of n-butyl methacrylate were dissolved in 30g of water to obtain liquid B;

[0035] S2. Add 7.2g TiO2 to the four-necked flask, then put it into the photoreactor, turn on the high-pressure mercury lamp after 30min to irradiate it and time it, and irradiate it for 2-4h; while irradiating, drop it into the reactor at the same time Add liquid A and liquid B, wherein the dropping time of liquid A is 5 h, and the dropping time of liquid B is 4 h; after the dropping is comple...

Embodiment 3

[0038] The present embodiment provides a preparation method of a viscosity-reducing polycarboxylate water-reducing agent, comprising the following steps:

[0039]S1. Add 200g of water to the four-necked flask, then add 240g of ethylene glycol monovinyl polyglycol ether, 28g of vinyl trifluoroacetate and 0.24g of sp-80, fully dissolve to form an aqueous system; add 0.24g of Vitamin C and 0.24g of mercaptopropionic acid were dissolved in 30g of water to obtain solution A; 8.6g of methacrylic acid and 3.38g of octadecyl methacrylate were dissolved in 30g of water to obtain solution B;

[0040] S2. Add 1.2g TiO2 to the four-necked flask, then put it into the photoreactor, turn on the high-pressure mercury lamp after 30min to irradiate it and time it, and irradiate it for 2-4h; drop it into the reactor at the same time while irradiating Add liquid A and liquid B, wherein the dropping time of liquid A is 5 h, and the dropping time of liquid B is 4 h; after the dropping is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com