Method for recovering high-purity tin-indium alloy from ITO target waste

A waste recycling and high-purity tin technology, which is applied in instruments, electrolytic components, optics, etc., can solve the problems of long electrolysis time and achieve the effect of improving the recovery rate and avoiding the short circuit of cathode and anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

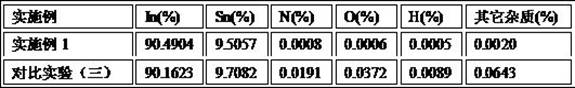

Examples

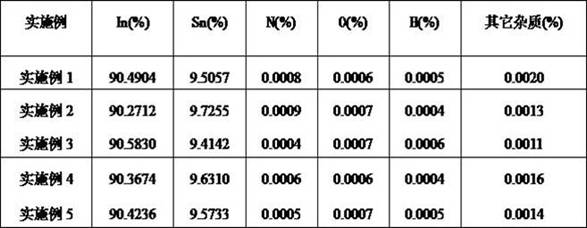

Embodiment 1

[0026] Example 1, Example 2 and Example 3 adopt the dimensions of the anode plate and the cathode plate: the length, width and thickness of the anode plate are 19.80cm, 13.80cm, and 0.90cm in sequence; the length, width and thickness of the cathode plate are 12.38cm, 8.63cm cm, 0.20 cm.

Embodiment 4

[0027] The dimensions of the anode plate and cathode plate used in Examples 4 and 5 are: the length, width and thickness of the anode plate are 20.20cm, 14.20cm, and 1.10cm in turn; the length, width and thickness of the cathode plate are 14.42cm, 10.15cm, and 0.30cm in turn .

[0028] Example 1:

[0029] (1) Dissolution: The anode plate and the titanium cathode plate are placed in the first electrolytic cell, and 800g / l sulfuric acid is used as the electrolyte for the first microcurrent electrolysis. The current density of the first microcurrent electrolysis is 40A / m. 2 , the temperature is 20°C, the electrolysis time is 120min, and the indium tin solution in the first electrolytic cell is taken;

[0030] (2) Primary purification: The anode plate and the titanium cathode plate are placed in the second electrolytic cell, and the indium tin solution is used as the electrolyte for the second micro-current electrolysis. The current density of the second micro-current electrolysi...

Embodiment 2

[0033] (1) Dissolution: The anode plate and the titanium cathode plate are placed in the first electrolytic cell, and 800g / l sulfuric acid is used as the electrolyte to carry out the first microcurrent electrolysis. The current density of the first microcurrent electrolysis is 45A / m. 2 , the temperature is 40°C, the electrolysis time is 160min, and the indium tin solution in the first electrolytic cell is taken;

[0034] (2) Primary purification: The anode plate and the titanium cathode plate are placed in the second electrolytic cell, and the indium tin solution is used as the electrolyte for the second micro-current electrolysis. The current density of the second micro-current electrolysis 60A / m 2 , the temperature is 40℃, and the electrolysis time is 130min;

[0035] (3) Secondary purification: filter out the moisture from the indium-tin alloy precipitate at the bottom of the second electrolytic cell and place it in a graphite crucible, then put it into a high-purity Ar su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com