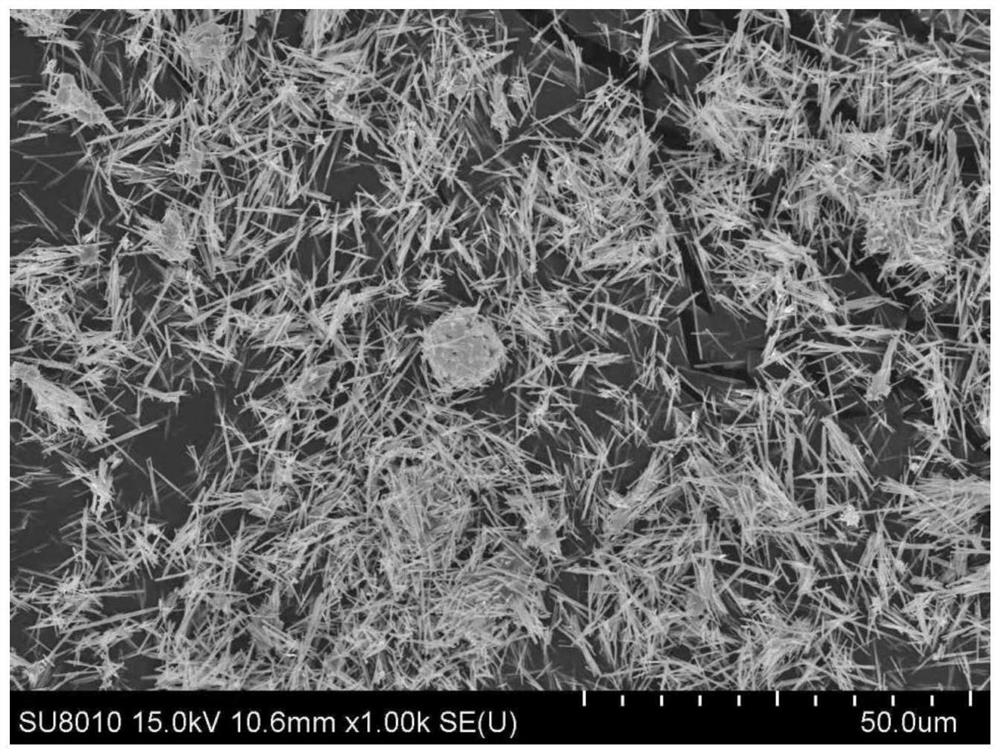

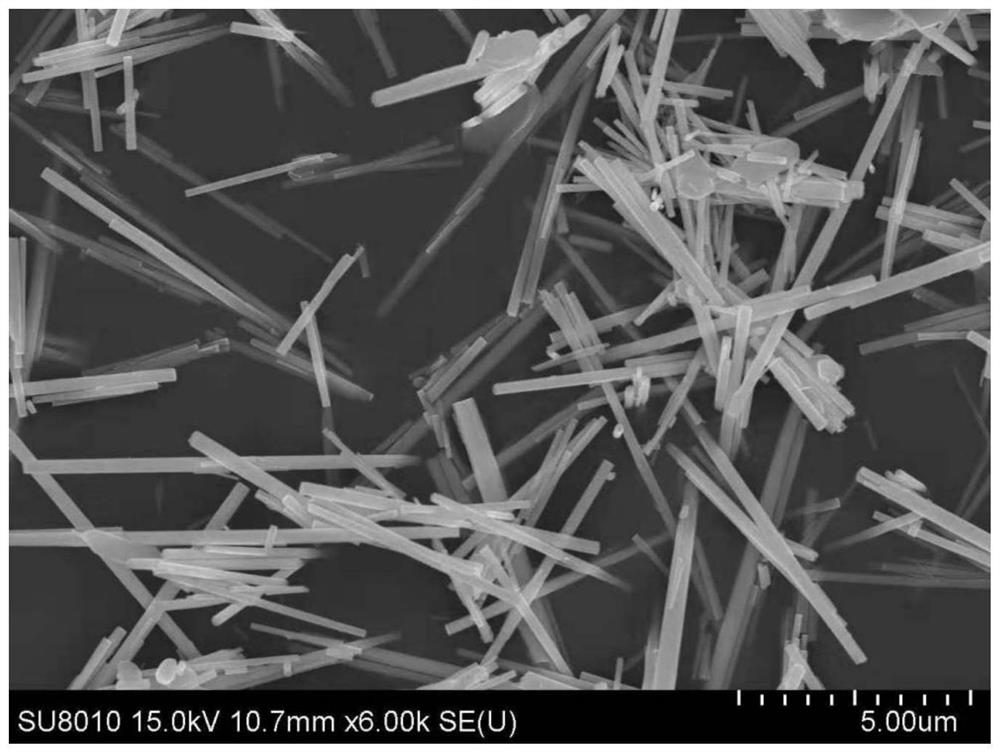

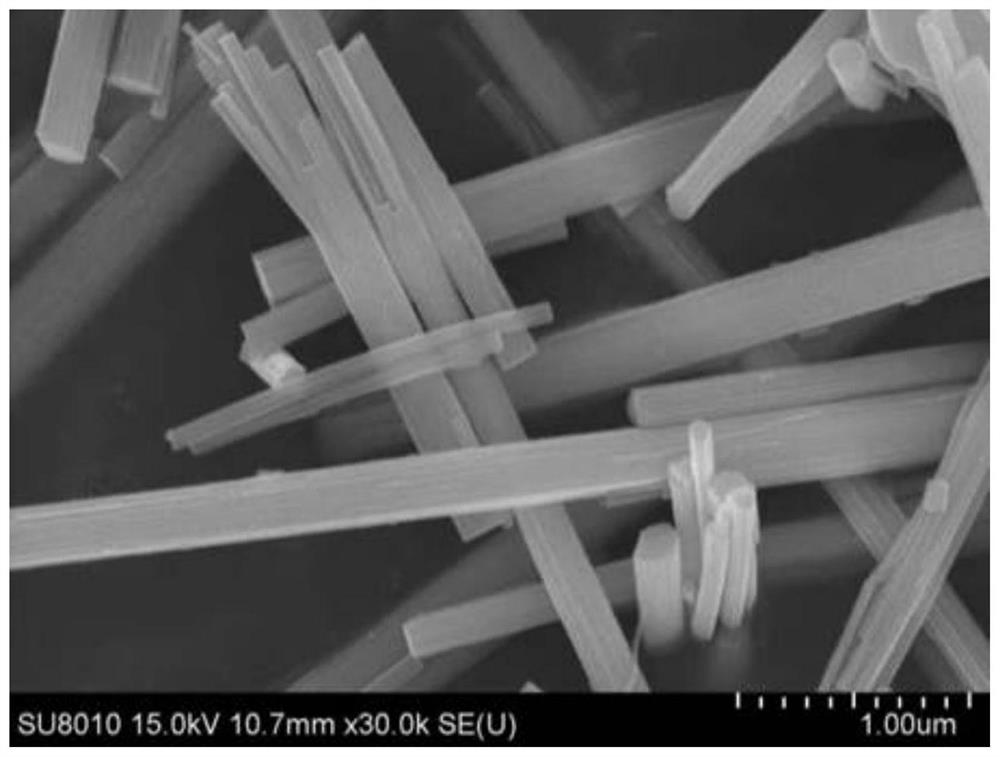

Nanofiber-cluster-shaped bismuth vanadate gas-sensitive material and preparation method thereof

A technology of nanofibers and gas-sensitive materials, which is applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of high energy consumption, complicated preparation process, long time consumption, etc., and achieves low equipment investment and improved separation rate. , the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of nanofiber cluster-shaped bismuth vanadate gas-sensing material, the steps are as follows:

[0048] Step 1: Measure a certain amount of concentrated nitric acid and deionized water, and configure a dilute nitric acid solution with a concentration of 1 to 4 mol / L;

[0049] Step 2, take by weighing a certain amount of bismuth nitrate pentahydrate and ammonium metavanadate, the mol ratio of bismuth nitrate pentahydrate and ammonium metavanadate is (1.01~1.2): 1; Bismuth nitrate pentahydrate and ammonium metavanadate are added respectively In a dilute nitric acid solution with a concentration of 1 to 4 mol / L, a mixed solution of bismuth nitrate with a concentration of 0.01 to 0.04 mol / L and a mixed solution of ammonium metavanadate with a concentration of 0.01 to 0.04 mol / L are obtained, and they are stirred at room temperature. Stir evenly at a rate of 400-1000 rad / min to form a colorless clear solution and a pale yellow clear solution;

[0050] S...

Embodiment 1

[0058] The preparation method of nanofiber cluster-shaped bismuth vanadate gas-sensing material, the steps are as follows:

[0059] Step 1: Measure a certain amount of concentrated nitric acid and deionized water, and configure a dilute nitric acid solution with a concentration of 1 mol / L;

[0060] Step 2, take by weighing a certain amount of bismuth nitrate pentahydrate and ammonium metavanadate, the mol ratio of bismuth nitrate pentahydrate and ammonium metavanadate is 1.01:1; Bismuth nitrate pentahydrate and ammonium metavanadate are added respectively and the concentration is 1mol / In L of dilute nitric acid solution, a mixed solution of bismuth nitrate with a concentration of 0.01 mol / L and a mixed solution of ammonium metavanadate with a concentration of 0.01 mol / L were obtained, and the stirring speed was 400 rad / min at room temperature. A colorless clear solution and a pale yellow clear solution were formed;

[0061] Step 3. The ammonium metavanadate mixed solution pr...

Embodiment 2

[0068] The preparation method of nanofiber cluster-shaped bismuth vanadate gas-sensing material, the steps are as follows:

[0069] Step 1, measure a certain amount of concentrated nitric acid and deionized water, and configure a dilute nitric acid solution with a concentration of 2 mol / L;

[0070] Step 2, take by weighing a certain amount of bismuth nitrate pentahydrate and ammonium metavanadate, the mol ratio of bismuth nitrate pentahydrate and ammonium metavanadate is 1.1:1; Bismuth nitrate pentahydrate and ammonium metavanadate are added respectively and the concentration is 2mol / In L of dilute nitric acid solution, a mixed solution of bismuth nitrate with a concentration of 0.02 mol / L and a mixed solution of ammonium metavanadate with a concentration of 0.02 mol / L were obtained, and the stirring speed was 600 rad / min at room temperature. A colorless clear solution and a pale yellow clear solution were formed;

[0071] Step 3. The ammonium metavanadate mixed solution pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com