Lithium ion battery composite diaphragm and preparation method thereof

A lithium-ion battery and composite diaphragm technology, which is applied in the field of battery diaphragm manufacturing, can solve the problems of large pores in polyester fiber non-woven fabrics and increase the ionic impedance of the diaphragm, and achieve energy saving for refining, lower ionic impedance, and small pore size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

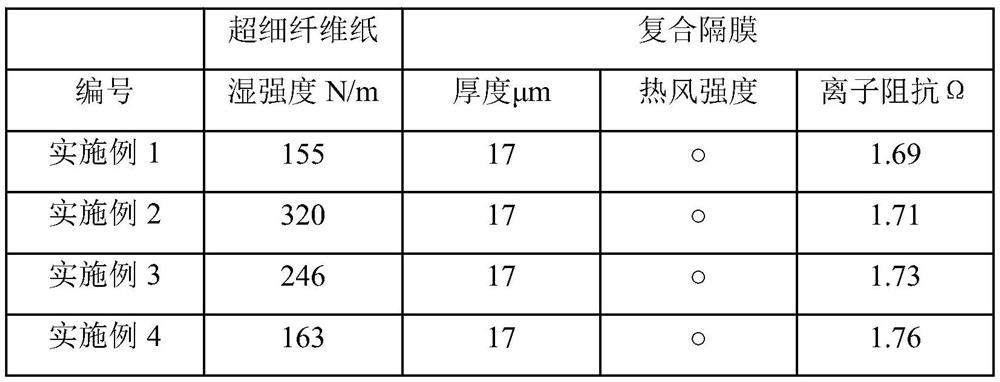

Embodiment 1

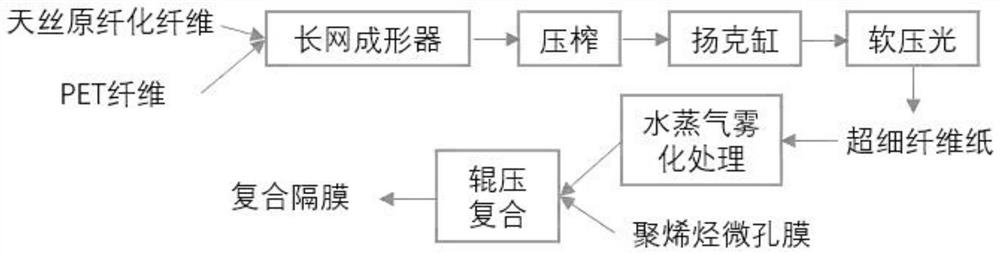

[0033] A lithium-ion battery composite separator is prepared by the following method:

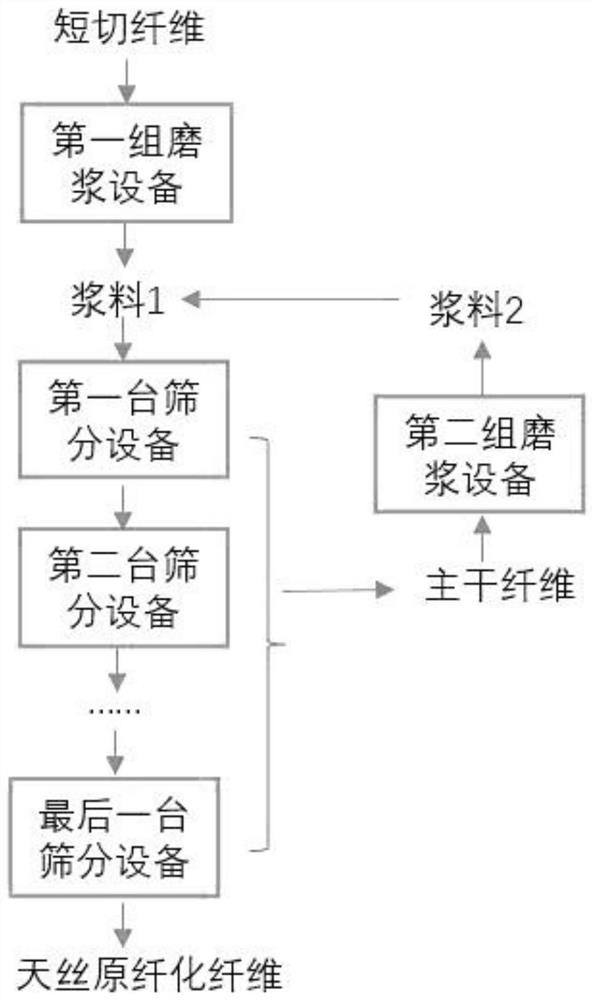

[0034] (1) Control the Tencel chopped fiber (length 4mm, diameter 12μm) at a concentration of 4%, use three disc refiner refining equipment for refining treatment, and the refining power is 180kw to obtain a beating degree of 40°SR. Slurry 1;

[0035] (2) Dilute the concentration of slurry 1 to 0.03% for screening treatment, and pass through three screening machines in turn. The screen meshes of the three screening machines are 100 mesh, 200 mesh and 300 mesh in turn, and the screen meshes of the three screening machines are intercepted. The slurry was mixed together to obtain slurry 2; then the slurry 2 was diluted to a concentration of 20%, treated with three disc refiners, and the refining power was 180kw to obtain slurry 3 with a beating degree of 70°SR; then Mixing slurry 3 and slurry 1 to form a closed sieving-refining circulation system, until all the slurry passes through a 300-mes...

Embodiment 2

[0040] A lithium-ion battery composite separator is prepared by the following method:

[0041] (1) Control the Tencel chopped fiber (length 4mm, diameter 12μm) at a concentration of 4%, use three disc refiner refining equipment for refining treatment, and the refining power is 180kw to obtain a beating degree of 40°SR. Slurry 1;

[0042] (2) Dilute the concentration of slurry 1 to 0.03% for screening treatment, and pass through three screening machines in turn. The screens of the three screening machines are 100 meshes, 200 meshes and 300 meshes in turn, and the screen meshes of the three screening machines are intercepted. The slurries were mixed together to obtain Slurry 2; then the Slurry 2 was diluted to a concentration of 20%, treated with three disc refiners, and the refining power was 180kw to obtain Slurry 3 with a beating degree of 70°SR; then Mix slurry 3 and slurry 1 to form a closed sieving-refining circulation system, until all the slurry passes through a 300-mes...

Embodiment 3

[0047] A lithium-ion battery composite separator is prepared by the following method:

[0048] (1) Control the Tencel chopped fiber (length 4mm, diameter 12μm) at a concentration of 4%, use three disc refiner refining equipment for refining treatment, and the refining power is 180kw to obtain a beating degree of 40°SR. Slurry 1;

[0049] (2) Dilute the concentration of slurry 1 to 0.03% for screening treatment, and pass through three screening machines in turn. The screen meshes of the three screening machines are 100 mesh, 200 mesh and 300 mesh in turn, and the screen meshes of the three screening machines are intercepted. The slurry was mixed together to obtain slurry 2; then the slurry 2 was diluted to a concentration of 20%, treated with three disc refiners, and the refining power was 180kw to obtain slurry 3 with a beating degree of 70°SR; then Mix slurry 3 and slurry 1 to form a closed sieving-refining circulation system, until all the slurry passes through a 300-mesh s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com