Lightweight foam concrete block thermal insulation material and preparation method thereof

A technology of concrete blocks and thermal insulation materials, applied in the field of foam concrete, can solve the problems of waste of resources, difficulty in degradation, and environmental pollution, and achieve the effect of accelerating hydration reaction and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

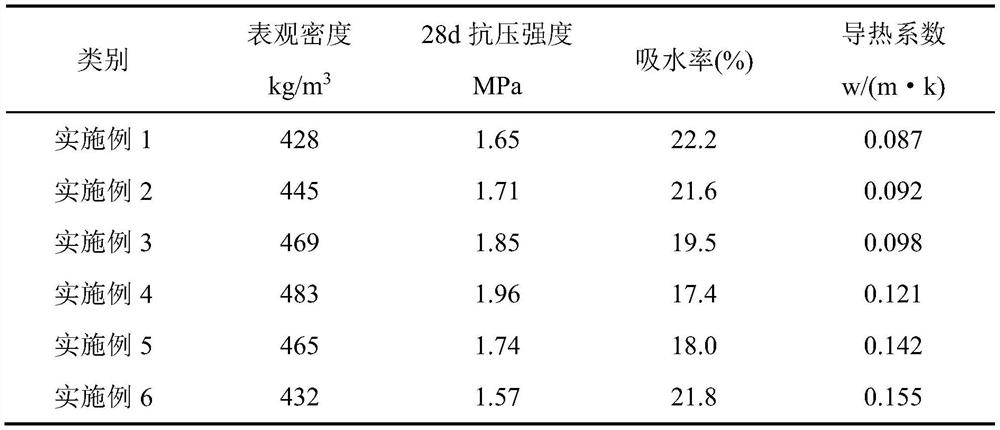

Examples

Embodiment 1

[0037]A lightweight foamed concrete block thermal insulation material using modified lobster shell powder and polyurethane waste as raw materials, in parts by mass, it is composed of the following components: 42.5 parts of Portland cement, 500 parts of modified lobster shell powder, 50 parts of modified lobster shell powder parts, 10 parts of waste polyurethane mixture, 2 parts of hydroxypropyl methylcellulose, 20 parts of expanded perlite, 2 parts of polyethylene glycol powder, 20 parts of silica fume, 20 parts of foaming agent, ZY-TPC polyhydroxy 2 parts of acid superplasticizer, 5 parts of polypropylene fiber, 5 parts of lithium carbonate, 4 parts of F0704 two-component water-based epoxy resin emulsion, 2 parts of F0705 two-component water-based epoxy curing agent, and 200 parts of tap water.

[0038] The preparation method of modified lobster shell powder is as follows:

[0039] The lobster shells are placed in a sodium bicarbonate solution with a concentration of 10wt%, s...

Embodiment 2

[0051] A lightweight foamed concrete block thermal insulation material using modified lobster shell powder and polyurethane waste as raw materials, in parts by mass, it is composed of the following components: 42.5 parts of Portland cement, 500 parts of modified lobster shell powder, 60 parts of modified lobster shell powder parts, 20 parts of waste polyurethane mixture, 2.5 parts of hydroxypropyl methylcellulose, 20 parts of perlite, 2.5 parts of polyethylene glycol powder, 25 parts of silica fume, 25 parts of foaming agent, ZY-TPC polyhydroxy acid 2.5 parts of high-performance water-reducing agent, 10 parts of polypropylene fiber, 10 parts of lithium carbonate, 5 parts of F0704 two-component water-based epoxy resin, 2.5 parts of F0705 two-component water-based epoxy curing agent, and 210 parts of tap water.

[0052] The preparation method of modified lobster shell powder is the same as that in Example 1.

[0053] The preparation method of the waste polyurethane mixture is th...

Embodiment 3

[0057] A lightweight foamed concrete block thermal insulation material using lobster shell powder and polyurethane waste as raw materials, in parts by mass, is composed of the following components: 500 parts of 42.5 Portland cement, 70 parts of modified lobster shell powder, 30 parts of waste polyurethane mixture, 3 parts of hydroxypropyl methylcellulose, 20 parts of perlite, 3 parts of polyethylene glycol powder, 30 parts of silica fume, 30 parts of foaming agent, ZY-TPC polyhydroxy acid high performance 3 parts of water reducing agent, 15 parts of polypropylene fiber, 15 parts of lithium carbonate, 6 parts of F0704 two-component waterborne epoxy resin emulsion, 3 parts of F0705 two-component waterborne epoxy curing agent, and 220 parts of tap water.

[0058] The preparation method of modified lobster shell powder is the same as that in Example 1.

[0059] The preparation method of the waste polyurethane mixture is the same as that in Example 1.

[0060] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com