Lightweight hanging brick for cement kiln grate cooler and preparation method thereof

A technology of grate cooler and cement kiln, applied in the field of refractory materials, can solve the problems of great difference in thermal expansion coefficient of composite structure, no obvious increase in porosity, influence of thermal conductivity of castables, etc., to achieve excellent corrosion resistance and improve porosity. efficiency and light weight, and the effect of improving the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing lightweight hanging bricks for a cement kiln grate cooler, comprising the following steps:

[0037] Step 1. Carry out batching according to the raw materials of the lightweight hanging bricks and their content, first blend the bauxite aggregate, the electrolytic cell sidewall aggregate and the organic silicon waste liquid, and mix for 5 to 15 minutes, Mixture A is made; then described bauxite fine powder, described Guangxi white mud fine powder, described elemental Si powder and described α-Al 2 O 3 The micropowder is added to the mixture A, and the mixture is continuously mixed for 15 to 20 minutes to obtain the mixture B; then the mixture B is trapped for 12 to 24 hours, and pressed and formed under the condition of 50 to 100 MPa to obtain a green body.

[0038] Step 2. Dry the green body at 100-120°C for 12-24h; in the sintering furnace, the temperature is first raised from room temperature to 1000°C at a rate of 4-6°C / min, and then heated at ...

Embodiment 1

[0040] A lightweight hanging brick for a cement kiln grate cooler and a preparation method thereof:

[0041] ① First, 60 parts of bauxite aggregate, 10 parts of electrolytic cell side wall aggregate and 3 parts of organic silicon waste liquid are blended, and mixed for 5 minutes to make mixture A; then 12 parts of bauxite fine powder, 4 parts of Guangxi white Mud fine powder, 1 part of elemental Si powder and 4 parts of α-Al 2 O 3 The micropowder was added to the mixture A, and the mixture was continued for 15 minutes to obtain the mixture B; then the mixture B was trapped for 12 hours, and pressed and formed under the condition of 50 MPa to obtain the china.

[0042] ② Dry the green body at 100°C for 24 hours; in the sintering furnace, the temperature is first heated from room temperature to 1000°C at a rate of 5°C / min, and then heated to 1350°C at a rate of 2°C / min, and kept for 3 hours. Cool, cut and grind to make lightweight hanging bricks.

[0043] The infrared radiati...

Embodiment 2

[0045] A lightweight hanging brick for a cement kiln grate cooler and a preparation method thereof:

[0046] ① First, 70 parts of bauxite aggregate, 5 parts of electrolytic cell side wall aggregate and 5 parts of organic silicon waste liquid are blended, and mixed for 10 minutes to make mixture A; then 8 parts of bauxite fine powder, 8 parts of Guangxi white Mud fine powder, 3 parts of elemental Si powder and 6 parts of α-Al 2 O 3 The micropowder was added to the mixture A, and the mixture was continued for 20 minutes to obtain the mixture B; then the mixture B was trapped for 24 hours, and pressed and formed under the condition of 100 MPa to obtain the china.

[0047] ② Dry the green body at 120°C for 24 hours; in the sintering furnace, the temperature is first heated from room temperature to 1000°C at a rate of 5°C / min, and then heated to 1450°C at a rate of 2.5°C / min, and kept for 8 hours. Cool, cut and grind to make lightweight hanging bricks.

[0048] The infrared radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

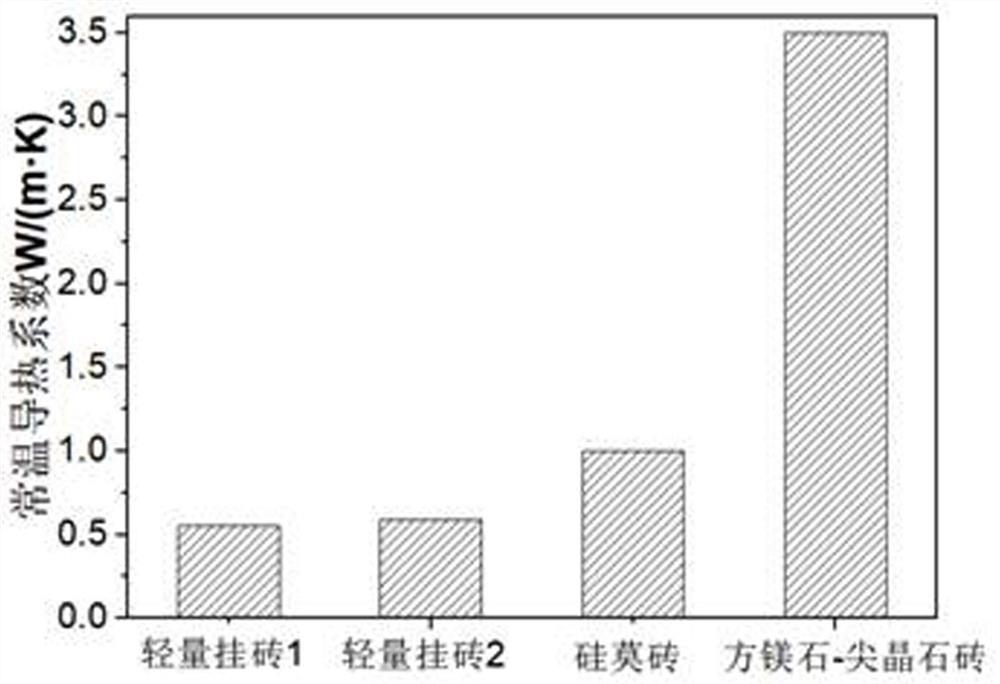

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com