Modified natural graphite material and preparation method thereof, negative pole piece and lithium ion battery

A natural graphite and modified technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to effectively improve the internal pores of natural graphite particles, high expansion rate of natural graphite negative electrode materials, and poor cycle performance, and achieve suitable The effect of expanding large-scale production, low cost and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The non-graphite converted carbon and carbon-containing organics will be described in detail below in conjunction with the preparation method of the modified natural graphite material.

[0094] Embodiments of the present application also provide a method for preparing a modified natural graphite material, comprising the following steps:

[0095] Mixing the natural graphite raw material with the first modifier to obtain the first mixture;

[0096] The first mixture is heated to a first temperature, evacuated, and sequentially carried out for the first time keeping, heating up to a second temperature, holding a second time, and cooling down to a third temperature; and

[0097] adding a second modifier to the first mixture to obtain a second mixture;

[0098] Then, the second mixture is heated to the first temperature, and vacuumized, and the first time insulation, the temperature increase to the second temperature, the second heat preservation, and the cooling to the thi...

Embodiment 1

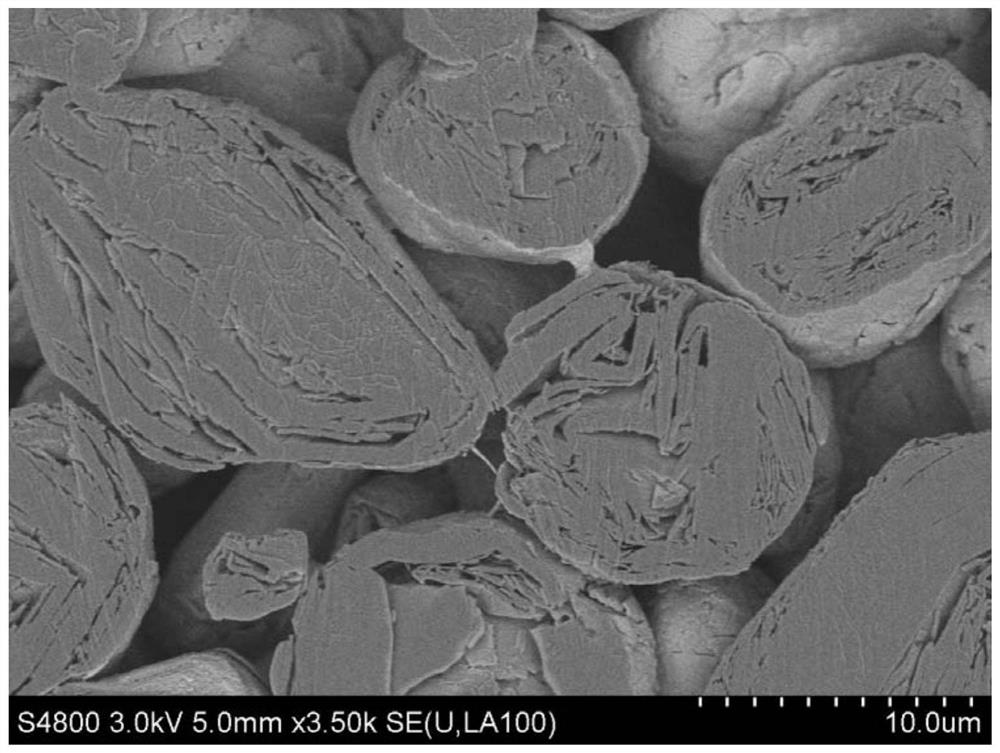

[0142] First, the 100-mesh flake graphite is mechanically pulverized, and then classified and shaped. The powder parameters after shaping are as follows (D50=15.6μm, Tap=0.912g / cc, D90 / D10=3.1, SSA is 8.6m 2 / g, the slice diagram is as follows figure 1 shown, the pore volume is 0.018 cm 3 / g).

[0143] After that, the obtained natural graphite raw material was mixed with the first modifier coal pitch (softening point of 160° C.) in a ratio of 0.85:0.07, and the mixing was carried out by VC mixing, and the mixing time was 30 minutes.

[0144] Then, put the mixed materials into the reaction kettle, and the reaction kettle adopts the method of gradually heating up, and the heating rate is 2 °C / min. While heating, the reaction kettle is kept in a state of constant stirring, and the temperature is raised to 190 °C, and the reaction kettle is pumped to pressure. is -0.1Mpa, and then kept for 2h; after the heat preservation, the reaction kettle was heated to 650 ° C and kept for 2 ...

Embodiment 2

[0148] First, 100 mesh flake graphite was mechanically pulverized, and then classified and shaped. The powder parameters after shaping were as follows (D50=8.1μm, Tap=0.874g / cc, D90 / D10=2.3, SSA was 9.7m 2 / g.

[0149]Then, the obtained natural graphite raw material was mixed with the first modifier petroleum pitch (softening point 250° C.) in a ratio of 0.92:0.04, and the mixing was carried out by VC mixing, and the mixing time was 30 minutes.

[0150] Then, put the mixed materials into the reaction kettle, and the reaction kettle adopts the method of gradually heating up, and the heating rate is 2 °C / min. While heating, the reaction kettle is kept in a state of constant stirring, and the temperature is raised to 280 °C, and the reaction kettle is pumped to pressure. After the heat preservation, the reaction kettle was heated to 650°C and kept for 2h; then the reaction kettle was cooled to about 250°C, and the second modifier was slowly added to the inside of the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com