Electrolyte for lithium battery, preparation method of electrolyte and lithium battery

A lithium battery and electrolyte technology, applied in the field of lithium battery electrolyte and its preparation, can solve the problem of low charge and discharge times, achieve high lithium conductivity, improve cycle stability and safety performance, and inhibit lithium dendrite growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

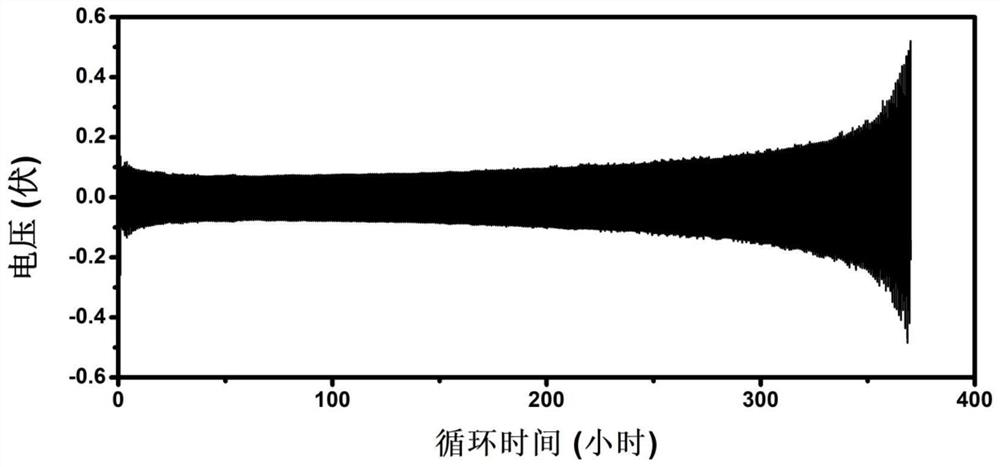

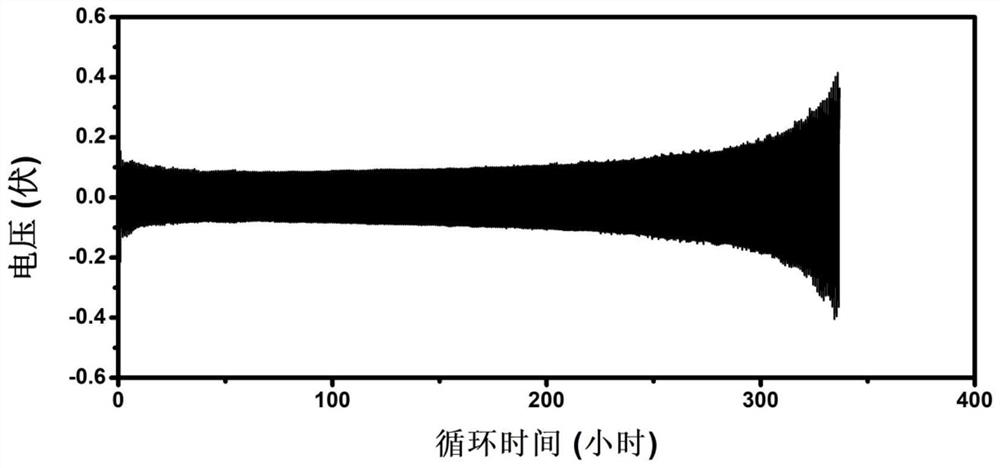

Image

Examples

preparation example Construction

[0040] A preparation method of the above-mentioned lithium battery electrolyte, comprising the following steps:

[0041] S1. In the glove box, H 2 O2 <0.1ppm, take an appropriate amount of lithium salt and dissolve it in the non-aqueous organic solution, and the concentration of the lithium salt is 1M to obtain the parent electrolyte;

[0042] S2, adding an additive whose mass percentage is 0.5-2.0 wt % in the parent electrolyte, and stirring evenly to obtain an electrolyte for a lithium battery.

[0043] A lithium battery containing the above-mentioned electrolyte for a lithium battery comprises a battery case, a positive electrode, a negative electrode, a separator and an electrolyte located in the battery case.

[0044] The positive electrode includes a positive electrode current collector and a positive electrode material on the positive electrode current collector, the positive electrode material including a positive electrode active material.

[0045] Alternatively, th...

Embodiment 1

[0051] in the glove box (H 2 O2 6 ), which was dissolved in a non-aqueous organic solution to obtain the parent electrolyte.

[0052] Lithium salt concentration: 1M lithium hexafluorophosphate (LiPF 6 );

[0053] Non-aqueous organic solvent: mixed solvent of ethylene carbonate (EC): dimethyl carbonate (DMC)=1:1 (v:v);

[0054] Adding 1.0wt% n-hexylboronic acid R to the parent electrolyte 2 The compound shown was uniformly stirred to obtain the implementation electrolyte solution 1.

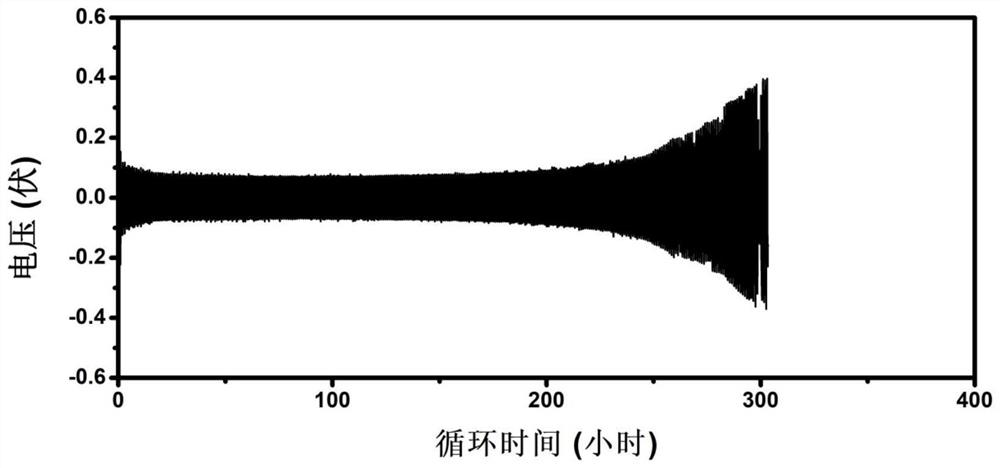

Embodiment 2

[0056] The electrolyte is prepared by the method described in Example 1, the difference is that n-propylboronic acid R with a mass fraction of 1.0 wt% is added to the parent electrolyte. 1 , the implementation of electrolyte 2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com