Secondary polymerization synchronous self-sealing ZIF-8 modified reverse osmosis membrane and preparation method thereof

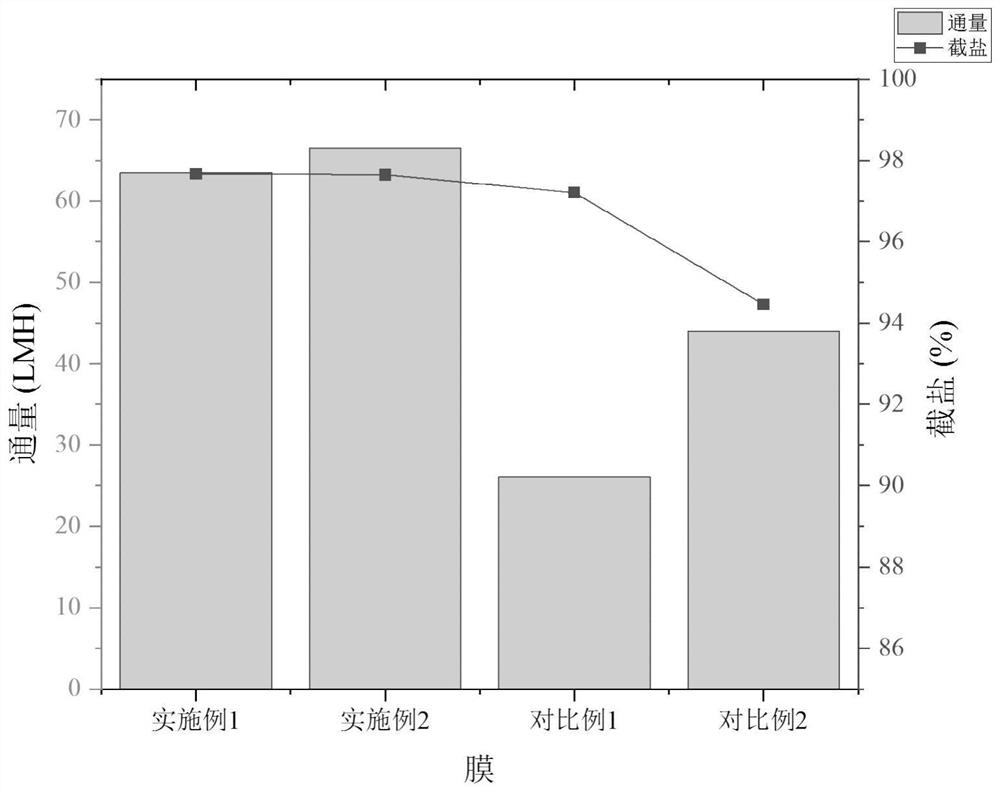

A ZIF-8, secondary polymerization technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of easy agglomeration of ZIF-8 materials, broken aromatic polyamide layer, limiting reverse osmosis membrane performance and other issues, to achieve good application prospects, simple preparation methods, and high-throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

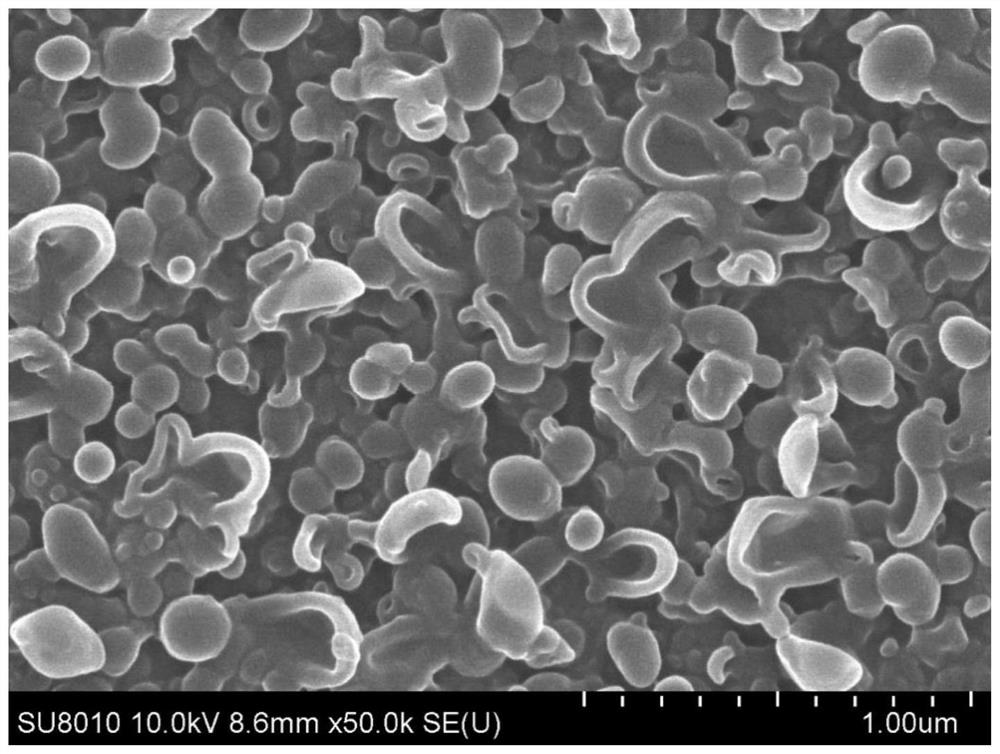

[0034] Example 1 Synchronous growth of ZIF-8 by secondary polymerization:

[0035] (1) spread the 0.12mol / L hexahydrate zinc nitrate aqueous solution on the polysulfone ultrafiltration support membrane, immerse it for 2min, pour out the solution, and dry the membrane;

[0036] (2) immersing the obtained membrane in a 2wt% m-phenylenediamine aqueous solution, after immersing for 3min, the solution is poured out, and the membrane is air-dried;

[0037] (3) contacting the obtained film with a 0.1 wt% trimesoyl chloride n-hexane solution, and after interfacial polymerization for 60s, the film is placed in a 60°C oven for 10min;

[0038] (4) placing the obtained film in a 75% isopropanol aqueous solution with a mass fraction of 3wt% m-phenylenediamine and 10wt% 2-methylimidazole for 10min, and drying the film;

[0039] (5) The obtained membrane was placed in a 0.2 wt% sodium bicarbonate aqueous solution for cleaning for 2 min, taken out, cleaned with deionized water, dried in the ...

Embodiment 2

[0042] Embodiment 2 changes the concentration of ZIF solution of secondary polymerization synchronous growth:

[0043] (1) spread the 0.12mol / L hexahydrate zinc nitrate aqueous solution on the polysulfone ultrafiltration support membrane, immerse it for 2min, pour out the solution, and dry the membrane;

[0044] (2) immersing the obtained membrane in a 2wt% m-phenylenediamine aqueous solution, after immersing for 3min, the solution is poured out, and the membrane is air-dried;

[0045] (3) contacting the obtained film with a 0.1 wt% trimesoyl chloride n-hexane solution, and after interfacial polymerization for 60s, the film is placed in a 60°C oven for 10min;

[0046] (4) placing the obtained film in a 75% isopropanol aqueous solution with a mass fraction of 5wt% m-phenylenediamine and 10wt% 2-methylimidazole for 10min, and drying the film;

[0047](5) The obtained membrane was placed in a 0.2 wt% sodium bicarbonate aqueous solution for cleaning for 2 min, taken out, cleaned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com