Process method for treating carbon fiber production process waste gas by using molecular sieve catalyst

A production process and catalyst technology, which is applied in the application and treatment field of molecular sieve catalysts, can solve the problems that cannot be processed at the same time, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Catalyst preparation

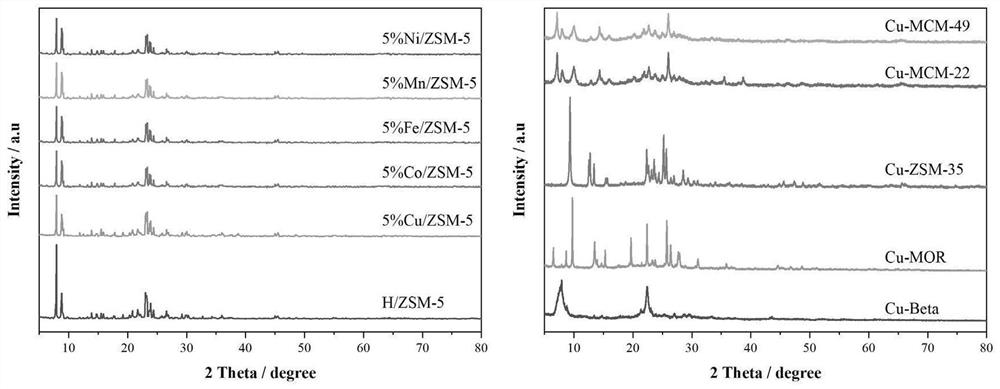

[0038] Take a certain amount of copper nitrate (weighed by the mass fraction of 5% Cu) and dissolve it in 200ml of deionized water to prepare a solution, and weigh 2.0g of SiO 2 / Al 2 O 3 = 30 H-ZSM-5 molecular sieves, mixed with the solution, fully stirred in a 40°C water bath for 8 hours, then slowly evaporated the water in the solution by a rotary vacuum evaporator, and then dried in a 110°C oven for 2 hours, Then, the temperature was raised to 550 °C for 4 h at a rate of 2 °C / min in an atmosphere of normal pressure air, and the obtained calcined product was a 5% Cu-ZSM-5 catalyst.

[0039] 2. Catalyst evaluation

[0040] The prepared catalyst was placed in a micro-fixed-bed quartz reactor, and the exhaust gas and O 2 (3vol%) mixed gas, the total flow is 100ml / min, and the air velocity of the mixed gas is 20000h -1, the reaction temperature range is 200 ~ 600 ℃. On-line gas quantitative analysis was performed using a Nicolet Nexus 470 ...

Embodiment 2

[0042] 1. Catalyst preparation

[0043] Take a certain amount of copper nitrate (weighed according to the mass fraction of 5% Cu load) and dissolve it in 200ml of deionized water to prepare a solution, and weigh 2.0g of SiO 2 / Al 2 O 3 = 30 H-Beta molecular sieves, mixed with the solution, fully stirred in a 40°C water bath for 8 hours, and then slowly evaporated the water in the solution by a rotary vacuum evaporator, then dried in a 110°C oven for 2 hours, and then placed in a rotary vacuum evaporator. The temperature was raised to 550 °C for 4 h at a rate of 2 °C / min in an atmosphere of normal pressure air, and the obtained calcined product was a 5% Cu-Beta catalyst.

[0044] 2. Catalyst evaluation

[0045] The prepared catalyst is placed in a micro-fixed-bed quartz reactor, and a certain amount of carbon fiber production process waste gas and O 2 (3vol%) mixed gas, the total flow is 100ml / min, and the air velocity of the mixed gas is 20000h -1 , the reaction temperatu...

Embodiment 3

[0047] 1. Catalyst preparation

[0048] Take a certain amount of copper nitrate (weighed according to the mass fraction of 5% Cu load) and dissolve it in 200ml of deionized water to prepare a solution, and weigh 2.0g of SiO 2 / Al 2 O 3 = 30 H-ZSM-35 molecular sieves, mixed with the solution, fully stirred in a 40°C water bath for 8 hours, then slowly evaporated the water in the solution by a rotary vacuum evaporator, and then dried in a 110°C oven for 2 hours, Then, the temperature was raised to 550 °C for 4 h at a rate of 2 °C / min in an atmosphere of normal pressure air, and the obtained calcined product was a 5% Cu-ZSM-35 catalyst.

[0049] 2. Catalyst evaluation

[0050] The prepared catalyst is placed in a micro-fixed-bed quartz reactor, and a certain amount of carbon fiber production process waste gas and O 2 (3vol%) mixed gas, the total flow is 100ml / min, and the air velocity of the mixed gas is 20000h -1 , the reaction temperature is 200 ~ 600 ℃. On-line gas quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com