Method for treating tail water of aquaculture pond

A treatment method and aquaculture technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. and production decline, to achieve the effect of accelerating oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

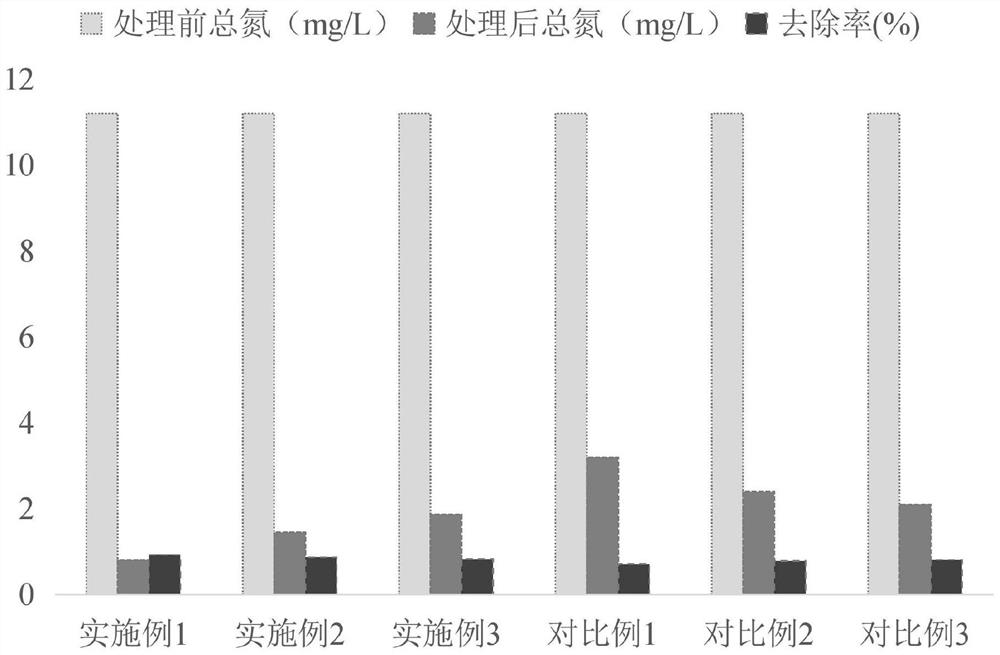

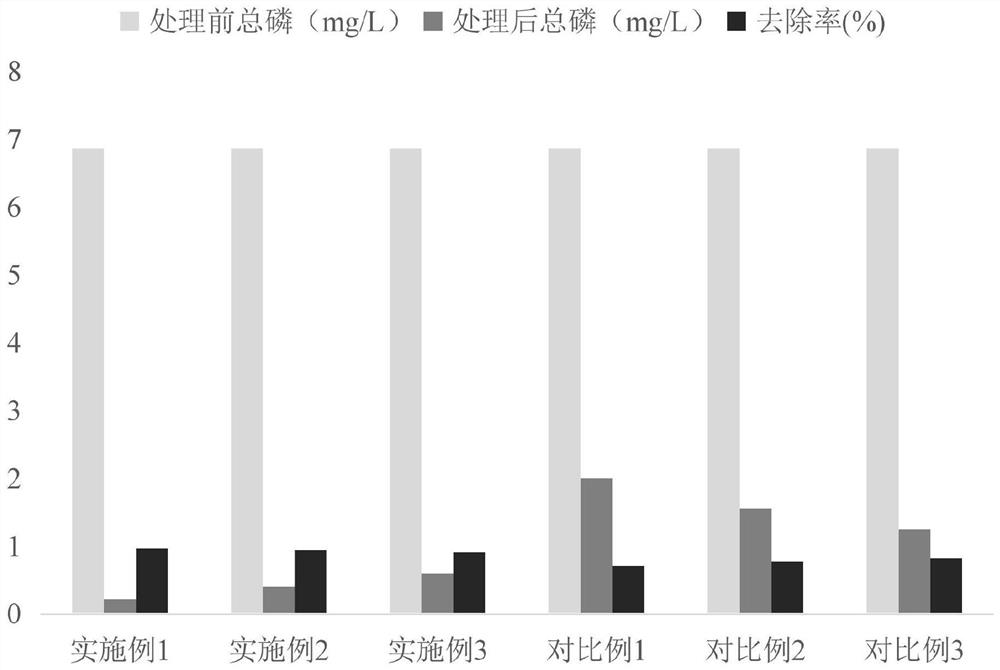

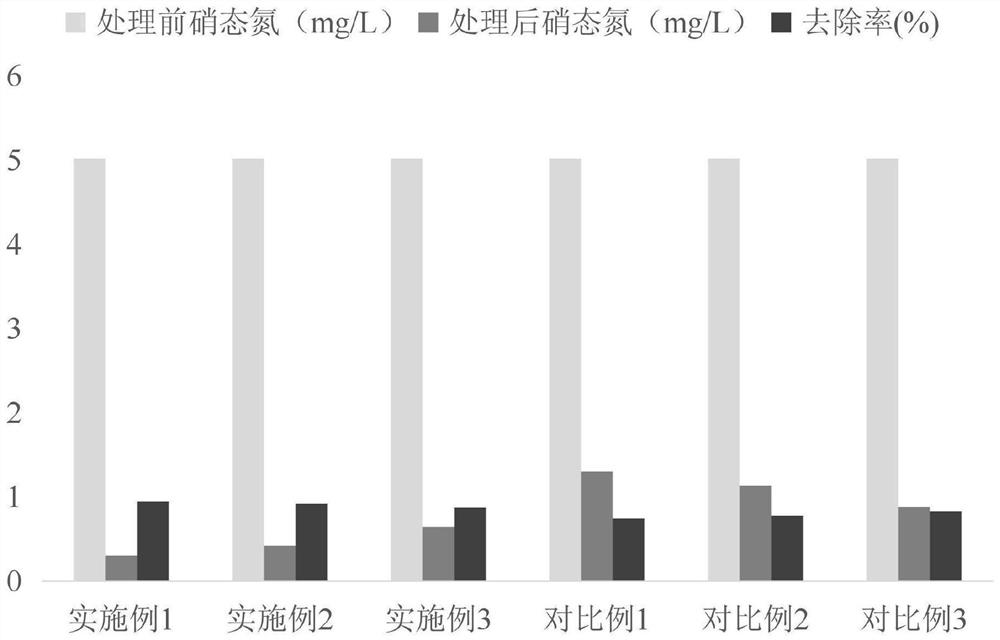

Examples

Embodiment 1

[0043] The present embodiment provides a method for treating tail water in an aquaculture pond, comprising the following steps:

[0044] In step 1, the first filtration treatment is performed on the tail water to remove larger suspended solids and excrement in the water body; Precipitated, and then processed by the second filtration to obtain the first aqueous phase and the first solid phase;

[0045] Step 2, the first solid phase is acclimated by anaerobic culture to obtain a second solid phase; then the second solid phase is mixed with the first water phase, followed by denitrification and aeration treatment to obtain a second solid phase. Accelerates the oxidative decomposition of organic matter while removing ammonia nitrogen in tail water;

[0046] In step 3, the treatment agent and the adsorbent are added to the aerated tail water and mixed evenly, and the reaction is carried out for 12 hours, so as to improve the purification of the tail water and obtain the purified t...

Embodiment 2

[0063] The present embodiment provides a method for treating tail water in an aquaculture pond, comprising the following steps:

[0064] In step 1, the first filtration treatment is performed on the tail water to remove larger suspended solids and excrement in the water body; Precipitated, and then processed by the second filtration to obtain the first aqueous phase and the first solid phase;

[0065] Step 2, the first solid phase is acclimated by anaerobic culture to obtain a second solid phase; then the second solid phase is mixed with the first water phase, followed by denitrification and aeration treatment to obtain a second solid phase. Accelerates the oxidative decomposition of organic matter while removing ammonia nitrogen in tail water;

[0066] Step 3, adding a treatment agent and an adsorbent to the aerated tail water to mix evenly, and react for 8 hours, so as to improve the purification of the tail water and obtain the purified tail water.

[0067] In the present...

Embodiment 3

[0083] The present embodiment provides a method for treating tail water in an aquaculture pond, comprising the following steps:

[0084] In step 1, the first filtration treatment is performed on the tail water to remove larger suspended solids and excrement in the water body; Precipitated, and then processed by the second filtration to obtain the first aqueous phase and the first solid phase;

[0085] Step 2, the first solid phase is acclimated by anaerobic culture to obtain a second solid phase; then the second solid phase is mixed with the first water phase, followed by denitrification and aeration treatment to obtain a second solid phase. Accelerates the oxidative decomposition of organic matter while removing ammonia nitrogen in tail water;

[0086] In step 3, the treatment agent and the adsorbent are added to the aerated tail water to mix evenly, and react for 16 hours, so as to improve the purification of the tail water and obtain the purified tail water.

[0087] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com