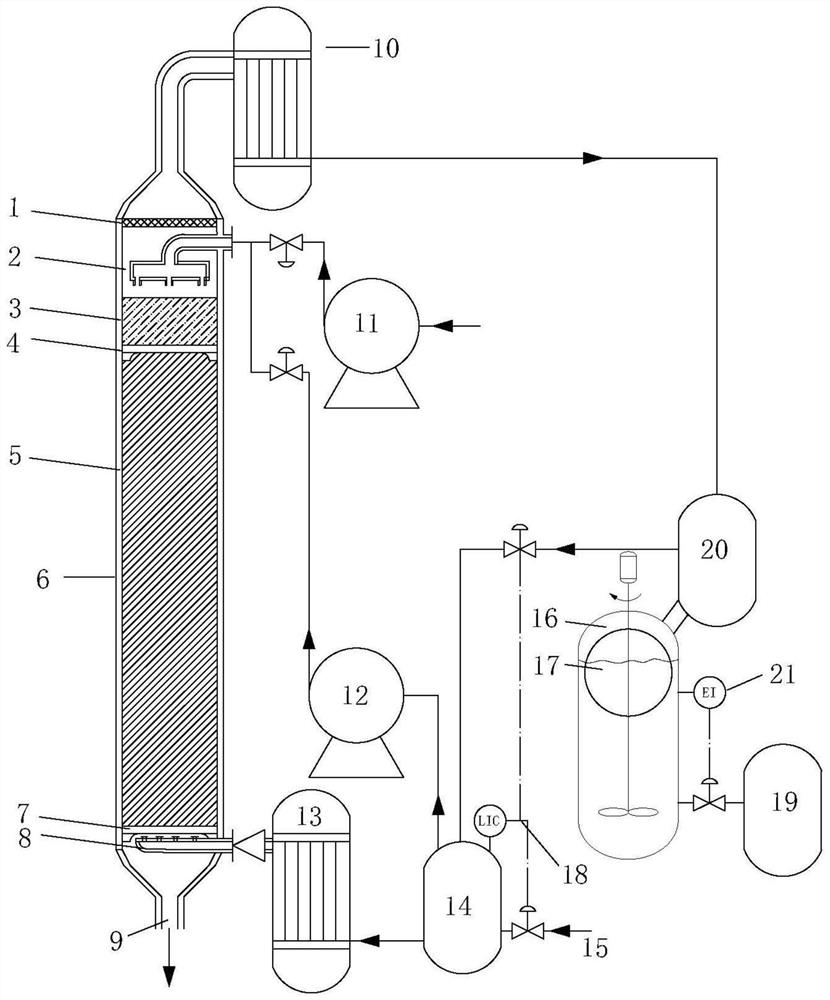

Reaction strengthening method and device for producing lactide by lactic acid liquid-phase one-step method

A lactide and lactic acid solution technology, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of increasing the mass transfer capacity of the two-liquid phase separation in the reflux liquid, low reaction rate and single-pass yield, etc. Achieve the effect of improving reaction rate and selectivity, continuous lactide production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 80wt% L-lactic acid solution 1.25g, H-β catalyst 0.5g, toluene 30mL, liquid-liquid extraction tank volume 20mL, system pressure 100kpa, oil bath 140°C, reaction time 3 hours, liquid-liquid extraction tank pre-filled with excess CaCl 2 Salt, CaCl during the reaction 2 Salt is always supersaturated. The one-way yield was 75.0%.

Embodiment 2

[0039] 80wt% L-lactic acid solution 1.25g, H-β catalyst 0.5g, toluene 30mL, liquid-liquid extraction tank volume 20mL, system pressure 100kpa, oil bath 140°C, reaction time 3 hours, liquid-liquid extraction tank pre-filled with excess BaCl 2 Salt, BgCl in progress 2 Salt is always supersaturated. The one-way yield was 77.7%.

Embodiment 3

[0041] 80wt% L-lactic acid solution 1.25g, H-β catalyst 0.5g, toluene 30mL, liquid-liquid extraction tank volume 20mL, system pressure 100kpa, oil bath 140°C, reaction time 3 hours, liquid-liquid extraction tank pre-filled with excess NaCl salt , the NaCl salt is always in a supersaturated state during the reaction process. The one-way yield was 68.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com