Graphene activated waterborne epoxy zinc-rich anticorrosive paint and preparation method thereof

A water-based epoxy zinc-rich, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the side effects of zinc corrosion deposit shielding protection, zinc powder cannot be oxidized, and electrons cannot be replenished, etc. , to achieve the effect of guaranteeing super scratch resistance, good toughness, and inhibiting infiltration and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

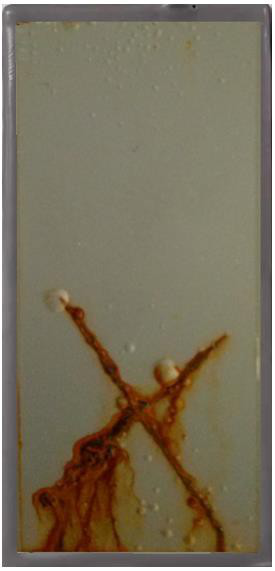

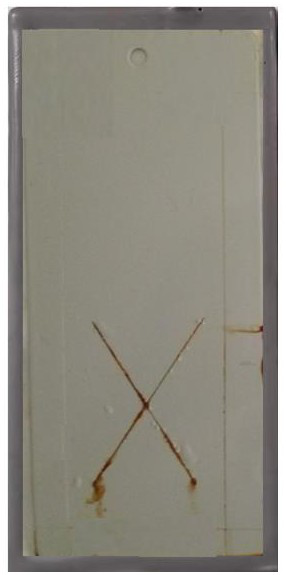

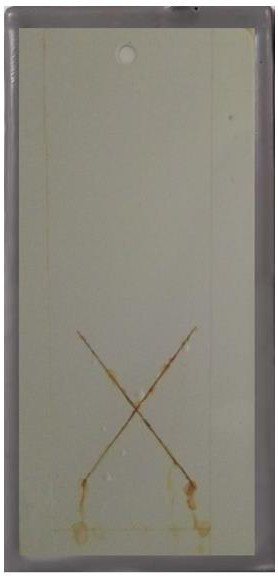

Image

Examples

Embodiment 1

[0038] The formula of a kind of graphene-activated water-based epoxy zinc-rich anti-corrosion coating described in this embodiment is composed of A and B components, and A component is made of the following raw materials by weight percentage:

[0039]

[0040] Component B is made from the following components and component percentage raw materials: waterborne epoxy resin curing agent 22%.

[0041] Preparation process: add a certain mass of water-based epoxy resin emulsion, dispersant, and graphene into the container at a speed of 1000 r / min, and stir for 60 to 90 minutes to ensure that no suspended fine particles are visible to the naked eye; then add a certain amount to the above mixed solution. The antifoaming agent and thixotropic agent of the mass number are stirred for 15 minutes at a rotating speed of 800r / min or until the stirring is uniform; a certain mass of zinc powder and deionized water are added to the above mixed solution, and the rotating speed is 1200r / min, s...

Embodiment 2

[0043] The formula of a kind of graphene-activated water-based epoxy zinc-rich anti-corrosion coating described in this embodiment is composed of A and B components, and A component is made of the following raw materials by weight percentage:

[0044]

[0045] Component B is made from the following components and component percentage raw materials: waterborne epoxy resin curing agent 22%.

[0046] The preparation process is exactly the same as that of Example 1.

Embodiment 3

[0048] The formula of a kind of graphene-activated water-based epoxy zinc-rich anti-corrosion coating described in this embodiment is composed of A and B components, and A component is made of the following raw materials by weight percentage:

[0049]

[0050] Component B is made from the following components and component percentage raw materials: waterborne epoxy resin curing agent 22%.

[0051] The preparation process is exactly the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com