Mining degradable hole washing liquid additive as well as preparation method and use method thereof

A technology of additives and hole washing liquid, which is applied in chemical instruments and methods, earthwork drilling, and wellbore flushing. The effect of construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the tackifier includes the following steps: uniformly mixing the nonionic cellulose ether particles, polyvinyl alcohol and antifoaming agent according to the above proportions to prepare;

[0043] The preparation method of the disintegrating agent comprises the following steps: the compound cellulase and the antifoaming agent are uniformly mixed and prepared according to the above ratio.

[0044] Another aspect of the embodiments of the present invention also provides the use of the above-mentioned mineral degradable hole washing liquid additive in drilling gas drainage.

[0045] Another aspect of the embodiments of the present invention also provides the use of the above-mentioned degradable pore washing liquid additive for mining in low-angle and negative-angle gas drainage.

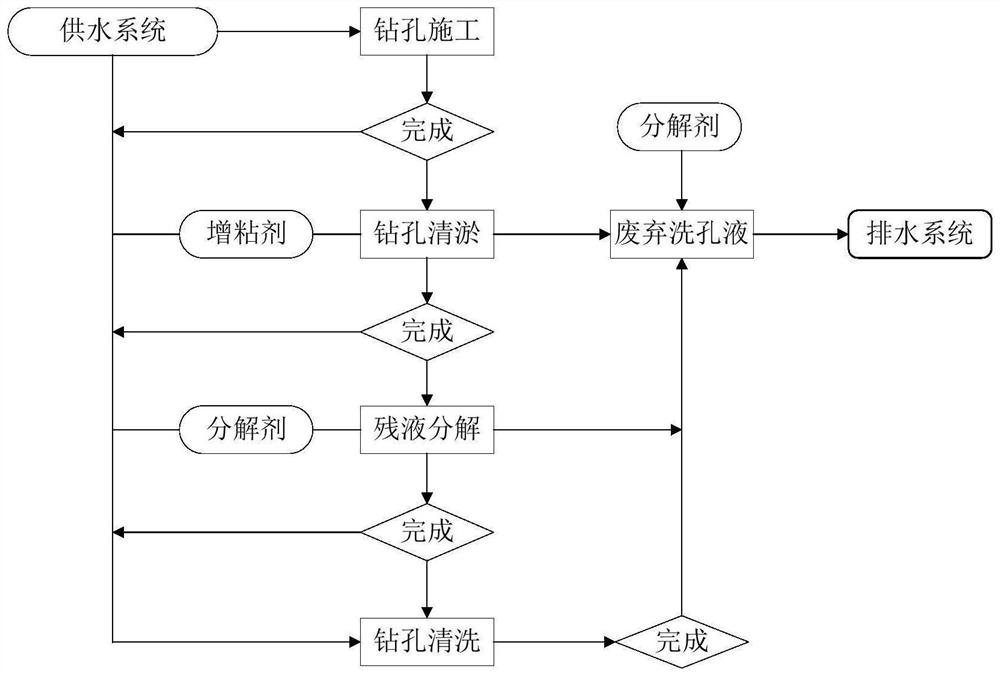

[0046] Another aspect of the embodiments of the present invention also provides a method for using the above-mentioned mineral degradable pore washing liquid additive (...

Embodiment 1

[0052] (1) Preparation of non-ionic cellulose ether particles, the non-ionic cellulose ether particles are prepared by granulating 60% ethanol solution and cellulose ether (HEC), and the particle size is 50-60 meshes.

[0053] (2) Preparation of tackifier: According to the drilling length (greater than 200m), the inclination angle (greater than -5°) and the coal seam firmness coefficient (greater than 0.5), according to the non-ionic cellulose ether particles (particle size 50-60 mesh) ): low viscosity polyvinyl alcohol: antifoaming agent (Zhongwan, W-320 type) = 1:0.1:0.05 mass ratio to prepare tackifier;

[0054] (3) Drilling dredging (cleaning): After the drilling construction is completed, the tackifier and water are mixed according to the mass ratio of the material-water ratio of 0.3:100, and the mixing and injection into the drilling are completed through the preparation device, and the drilling is carried out. Hole dredging (cleaning);

[0055] (4) Preparation of decom...

Embodiment 2

[0059] (1) Preparation of non-ionic cellulose ether particles, the non-ionic cellulose ether particles are prepared by granulating 60% ethanol solution and hydroxypropyl methylcellulose (HPMC), and the particle size is 60-80 meshes.

[0060] (2) Preparation of tackifier: according to the drilling length (greater than 100m), the inclination angle (less than -5°) and the coal seam firmness coefficient (less than 0.5), according to the non-ionic cellulose ether particles (particle size 60-80 mesh) ): low-viscosity polyvinyl alcohol: antifoaming agent (Zhongwan, W-320 type) = 0.8:0.2:0.03 mass ratio to prepare tackifier;

[0061] (3) Drilling dredging (cleaning): After the drilling construction is completed, mix the tackifier and water according to the mass ratio of the material-water ratio of 0.4:100, and complete the mixing and injection into the drilling through the preparation device. Hole dredging (cleaning);

[0062] (4) Preparation of decomposition agent: according to comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com