Method for improving gas production rate by adding sodium propionate to domesticate microbial community of anaerobic fermentation system and application of method

A microbial community and anaerobic fermentation technology, applied in the field of environmental protection, can solve the problems of secondary pollution of the atmosphere and soil, threats to the ecological environment and human activities, etc. The effect of improving methane production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for improving gas production by adding sodium propionate to domesticate microbial communities in an anaerobic fermentation system, comprising the following steps:

[0038] Step 1) Controlling the solid content of the biogas slurry and biogas residue mixture to 15%;

[0039] Step 2) Add 400 mL of culture medium to each liter of biogas slurry and biogas residue mixture treated in step 1), and after mixing evenly, take 700 mL of the mixture and put it into an anaerobic reactor with a volume of 1 L,

[0040] Step 3) Continue to add sodium propionate to the anaerobic digestion reactor of step 2), and the addition amount is 1g, 2g, 3g, 4g, 5g, 6g, 8g, 10g, 12g, 14g, 16g, 18g per liter respectively , 20g, 22g, 24g, 26g, 28g, 30g, 35g, 40g, 3 parallel for each concentration, pass nitrogen for ten minutes, cover for anaerobic digestion reaction;

[0041] The medium in described step 2) includes a large number of elements: NH 4 Cl 400mg / L, MgSO 4 ·6H 2 O 250mg / L, KCl...

Embodiment 2

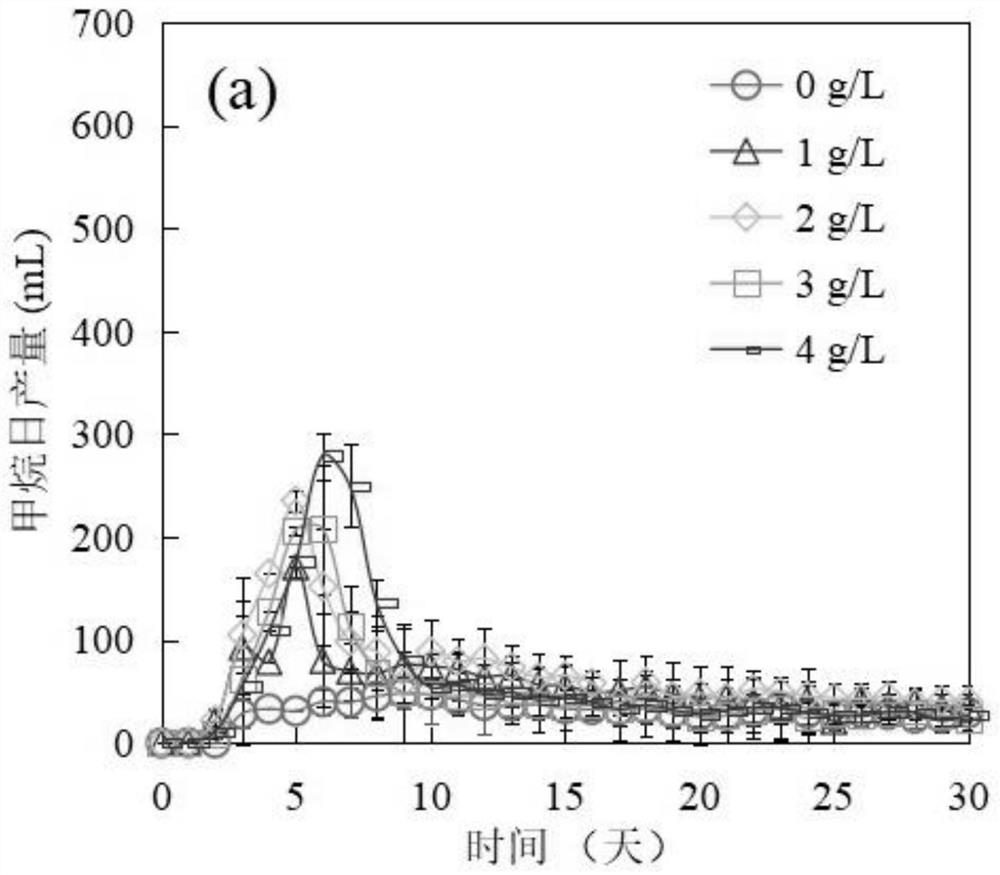

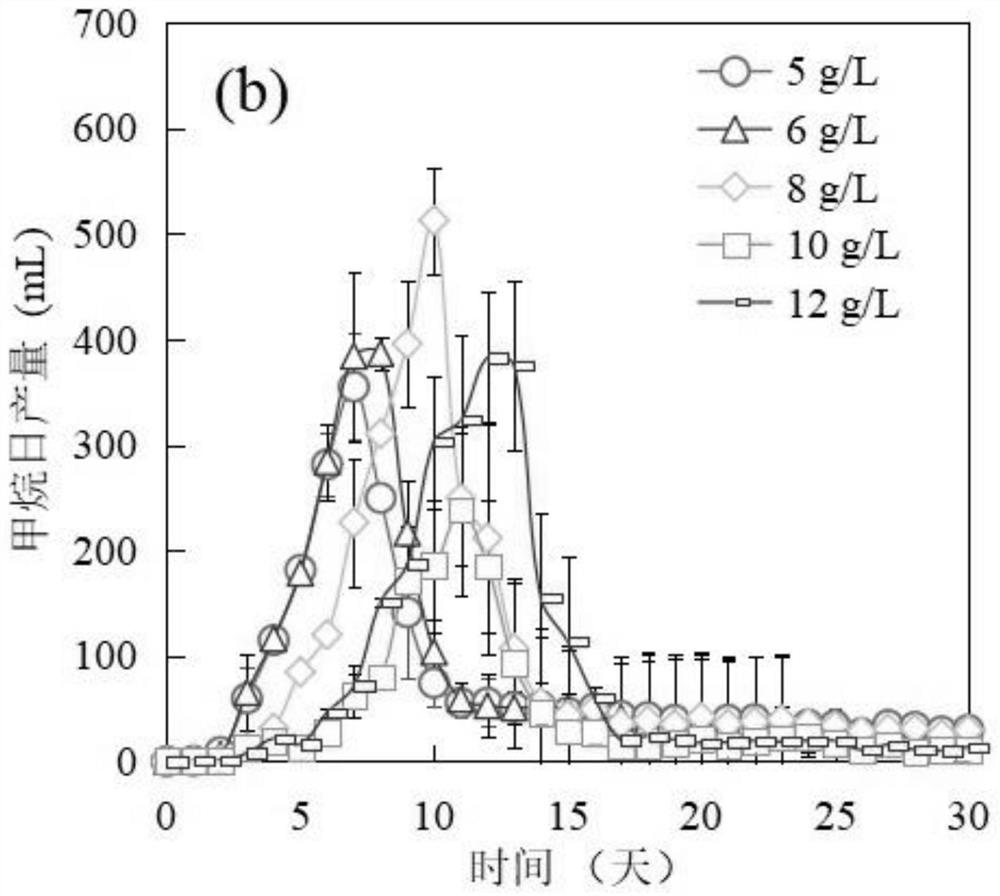

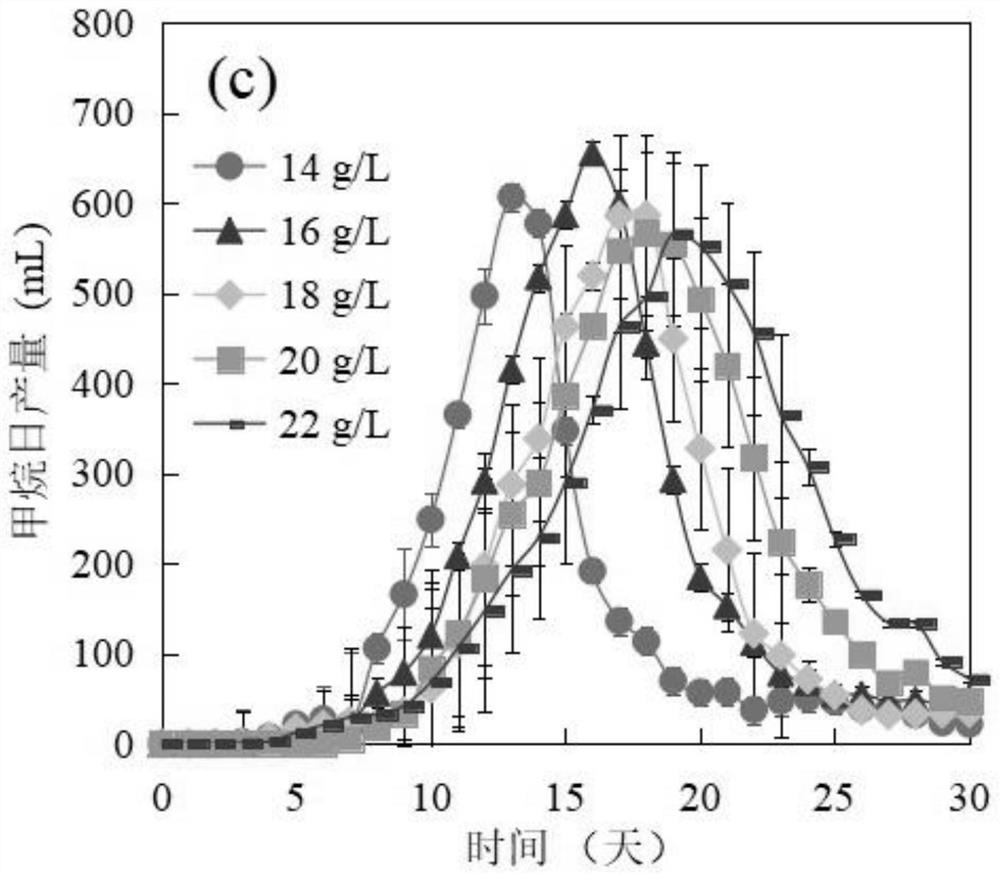

[0047] On the 1st to 30th day of the anaerobic digestion reaction, the biogas meter (Geotech, Biogass5000, UK) was used to measure the anaerobic digestion reactors with sodium propionate added in each concentration in Example 1 and without sodium propionate added in Comparative Example 1. The amount of methane produced, the results are shown in Table 1, through counting analysis, make a curve, the results are as follows Figures 1 to 8 shown, where Figure 1 to Figure 4 For adding 0g / L, 1g / L, 2g / L, 3g / L, 4g / L, 5g / L, 6g / L, 8g / L, 10g / L, 12g / L, 14g / L, 16g / L , 18g / L, 20g / L, 22g / L, 24g / L, 26g / L, 28g / L, 30g / L, 35g / L, 40g / L sodium propionate daily output of methane with time change curve , Figures 5 to 8 For adding 0g / L, 1g / L, 2g / L, 3g / L, 4g / L, 5g / L, 6g / L, 8g / L, 10g / L, 12g / L, 14g / L, 16g / L , 18g / L, 20g / L, 22g / L, 24g / L, 26g / L, 28g / L, 30g / L, 35g / L, 40g / L of sodium propionate after the cumulative methane production curve graph .

[0048] Table 1 The amount of methane produced in th...

Embodiment 3

[0055] On the 0d, 7d, 10d, 15d, and 30d of the anaerobic digestion reaction, respectively, the samples were subjected to DNA extraction, PCR amplification, library construction, and high-throughput sequencing on the computer. According to the taxonomic analysis example The community structure at the bacterial phylum level in the anaerobic digestion reactors with sodium propionate at each concentration added in 1 and without sodium propionate added in Comparative Example 1, the results are shown in Table 2, and the relative abundance map of the bacterial phylum level is drawn, The result is as Figure 9 shown. Among them, C0-D0 means: C is the abbreviation of content concentration, 0 is 0mg / L, and D0 is the 0th day. Bacteria with relative abundance below 10% were classified as Other.

[0056] Table 2 Community structure (%) of bacterial phylum level in anaerobic digestion reactors with various concentrations of sodium propionate added

[0057]

[0058]

[0059] From Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com