Extra-high voltage waterproof fireproof ceramic shielding tube type pouring bus

A technology of refractory ceramics and shielding tubes, applied in the direction of power cables, cables, insulated conductors with shielding layer/conductive layer, etc., can solve the problems of easy aging, high energy consumption, short life, etc., and achieve good comprehensive performance and energy consumption. Low, long-lived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The problem to be solved by the present invention is to change the form of the existing outdoor low-altitude high-voltage power transmission carrier, improve various performance parameters of the carrier (protection level, insulation and temperature resistance level, current carrying capacity, power loss, installation space, etc.) A tubular cast busbar that operates safely in harsh environments.

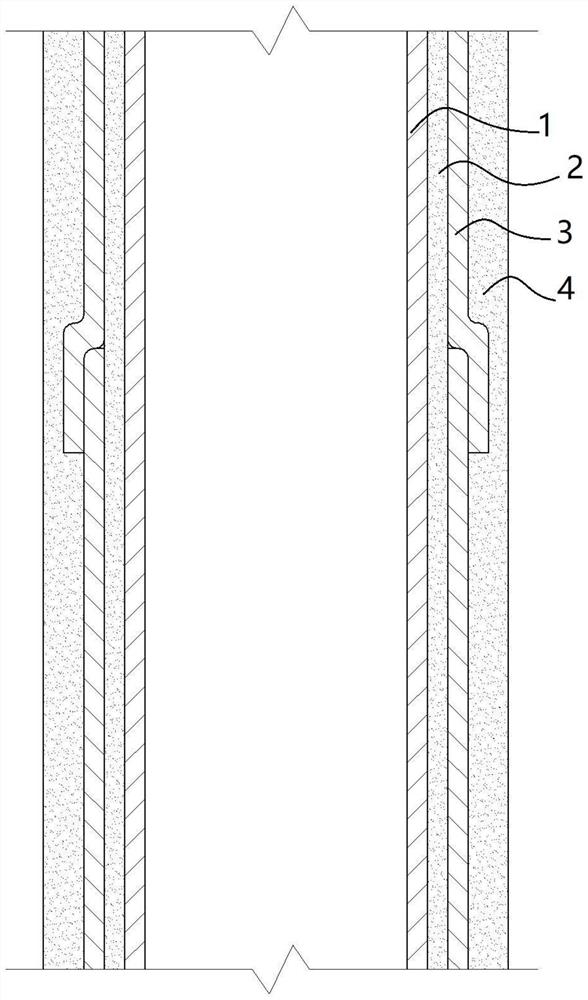

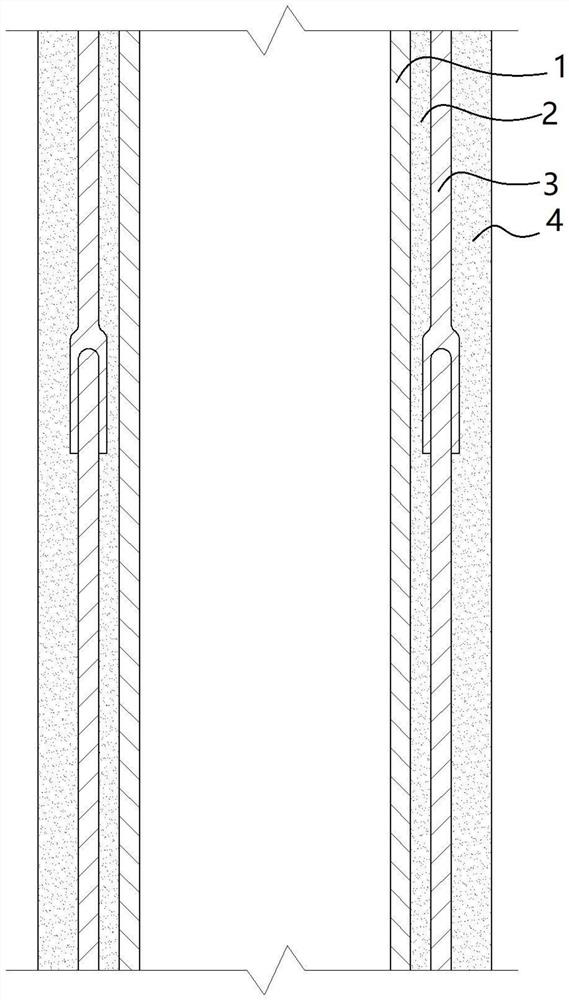

[0030] like figure 1 As shown, an ultra-high voltage waterproof and refractory ceramic shielded tubular cast busbar includes a tubular conductor 1 , an insulating waterproof layer 2 , a ceramic arc shielding layer 3 and a protective layer 4 from the inside to the outside.

[0031] In this scheme, the ceramic arc shielding layer 3 is used to maximize the insulation coefficient and shield the arc, and the withstand voltage range can reach 10KV ~ 800KV. An insulating waterproof layer 2 is arranged between the tubular conductor 1 and the ceramic arc shielding layer 3, and the she...

Embodiment 2

[0035] Compared with Embodiment 1, the difference in this embodiment is that the adjacent ceramic arc shielding layers are connected by a plug-in structure, and the plug-in structure includes a slot axially arranged at the end of one of the ceramic arc shielding layers and a Plug on the end of the other ceramic arc shield. The use of the plug-in structure can double the length of the connection seam of the shielding layer of the arc wire, and can further shorten the interphase spacing.

[0036] The materials used in this technical solution are as follows:

[0037] The ceramic arc shielding layer adopts alumina or zirconia ceramics. Has better wear resistance, high temperature wear resistance. This embodiment uses zirconia ceramics.

[0038] The insulating waterproof layer and the protective layer are made of epoxy resin composite material. It can be waterproof and insulating, wear-resistant and flame-retardant.

[0039] The insulating waterproof layer includes epoxy resin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap