Gel polymer electrolyte for magnesium ion battery and preparation method of gel polymer electrolyte

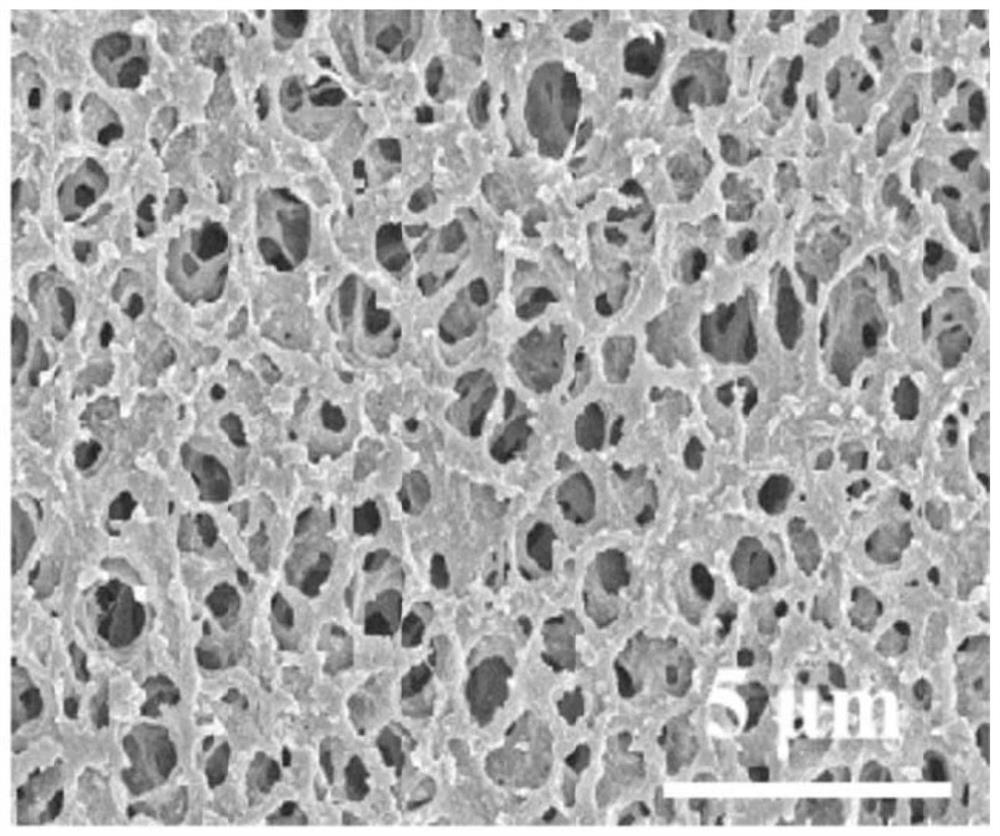

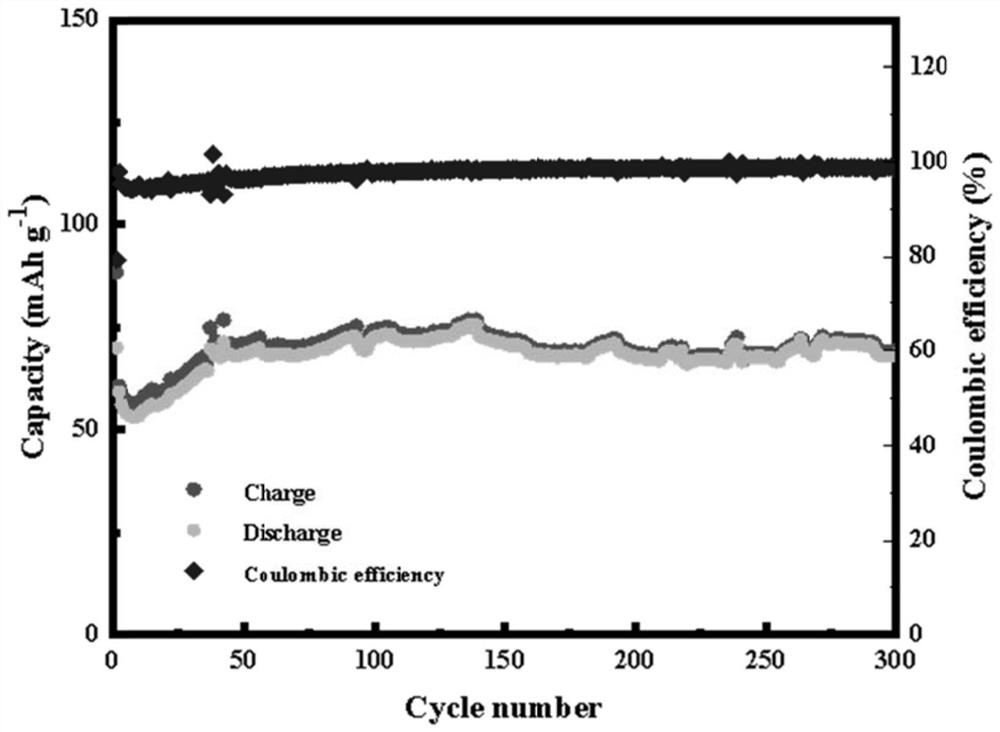

A gel polymer and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as unfavorable magnesium ion transmission, and achieve the effects of promoting rapid transmission, delaying nucleation rate, and enriching porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]A preparation method of a high-performance gel polymer electrolyte for magnesium ion batteries, comprising the following steps:

[0044] (a) Preparation of MC

[0045] Weigh 2g of cellulose into a beaker, then add 5ml of 1M NaOH / 6M KSCN solution, swell at room temperature for 30min, and filter with suction; transfer the obtained filter cake to a flask, add 20ml of acrylonitrile, and react at 35°C for 2h. After the reaction, the reactant was neutralized with 1M glacial acetic acid to neutrality, and filtered with suction; the product was washed alternately with ethanol and distilled water, and dried in vacuum at 60°C. Finally got the MC product.

[0046] (b) Preparation of MC films

[0047] Weigh 1.0g of MC powder and 10ml of DMAC into a beaker, heat and stir at 70°C for 6 hours to obtain a uniform and stable MC casting solution; pour the prepared casting solution on the surface of the glass plate, and use a scraper to remove the casting solution. Scrape coated on a gl...

Embodiment 2

[0051] A preparation method of a high-performance gel polymer electrolyte for magnesium ion batteries, comprising the following steps:

[0052] (a) Preparation of MC

[0053] Weigh 2g of cellulose into a beaker, then add 5ml of 1M NaOH / 6M KSCN solution, swell at room temperature for 60min, and filter with suction; transfer the obtained filter cake to a flask, add 25ml of acrylonitrile, and react at 38°C for 2.5h . After the reaction, the reactant was neutralized with 1M glacial acetic acid to neutrality, and filtered with suction; the product was washed alternately with ethanol and distilled water, and dried under vacuum at 70°C. Finally got the MC product.

[0054] (b) Preparation of MC films

[0055] Weigh 1.1g of MC powder and 10ml of DMAC into a beaker, heat and stir at 60°C for 7 hours to obtain a uniform and stable MC casting solution; pour the prepared casting solution on the surface of the glass plate, and use a scraper to remove the casting solution. Scrape coated...

Embodiment 3

[0059] A preparation method of a high-performance gel polymer electrolyte for magnesium ion batteries, comprising the following steps:

[0060] (a) Preparation of MC

[0061] Weigh 2g of cellulose into a beaker, then add 5ml of 1M NaOH / 6M KSCN solution, swell at room temperature for 50min, and filter with suction; transfer the obtained filter cake to a flask, add 23ml of acrylonitrile, and react at 36°C for 2h. After the reaction was completed, the reactant was neutralized with 1M glacial acetic acid, and filtered with suction; the product was washed alternately with ethanol and distilled water, and dried at 65°C under vacuum. Finally got the MC product.

[0062] (b) Preparation of MC films

[0063] Weigh 1.05g of MC powder and 10ml of DMAC into a beaker, heat and stir at 65°C for 6.5h to obtain a uniform and stable MC casting solution; pour the prepared casting solution on the surface of the glass plate, and use a scraper to remove the casting solution. The liquid was scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com