Tin-containing metal oxide catalyst as well as preparation method and application thereof

An oxide and catalyst technology, applied in the field of tin-containing metal oxide catalyst and its preparation, can solve the problem of incomplete conversion of NOx, achieve excellent N2 generation selectivity, be beneficial to industrial production, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

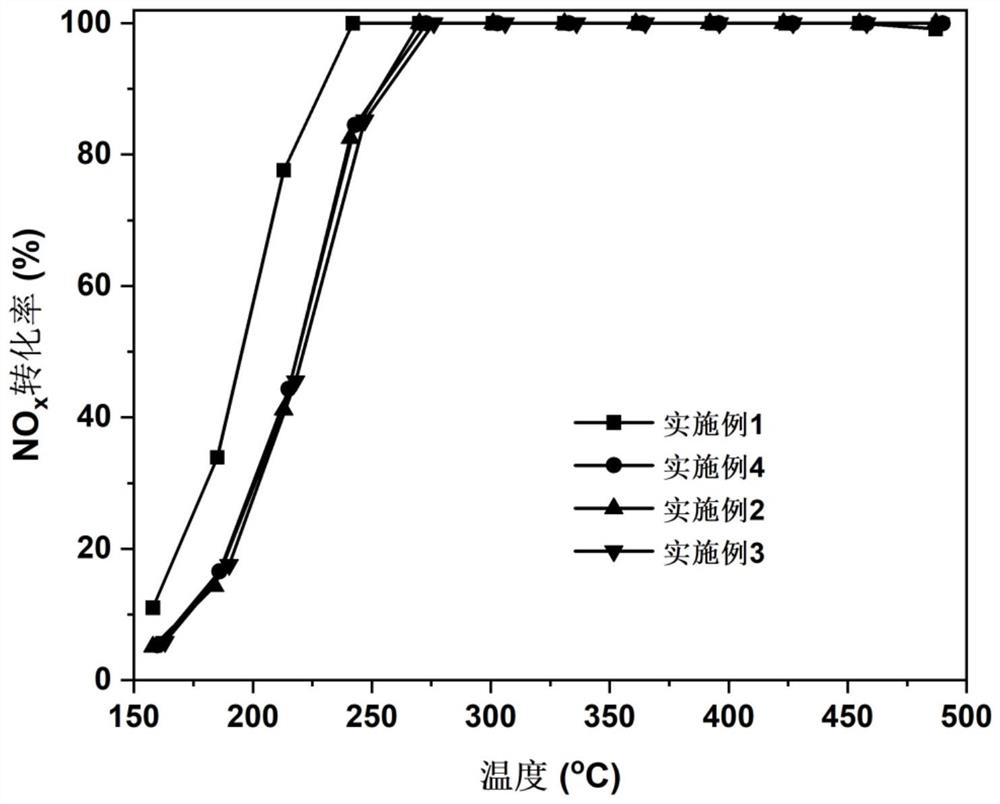

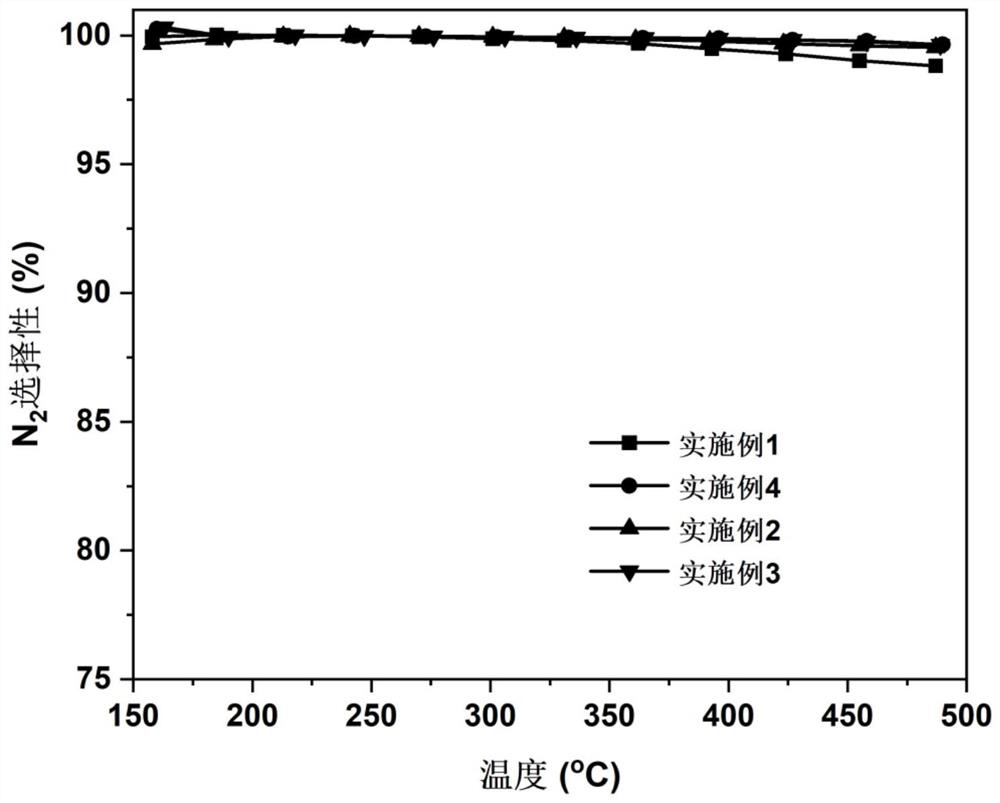

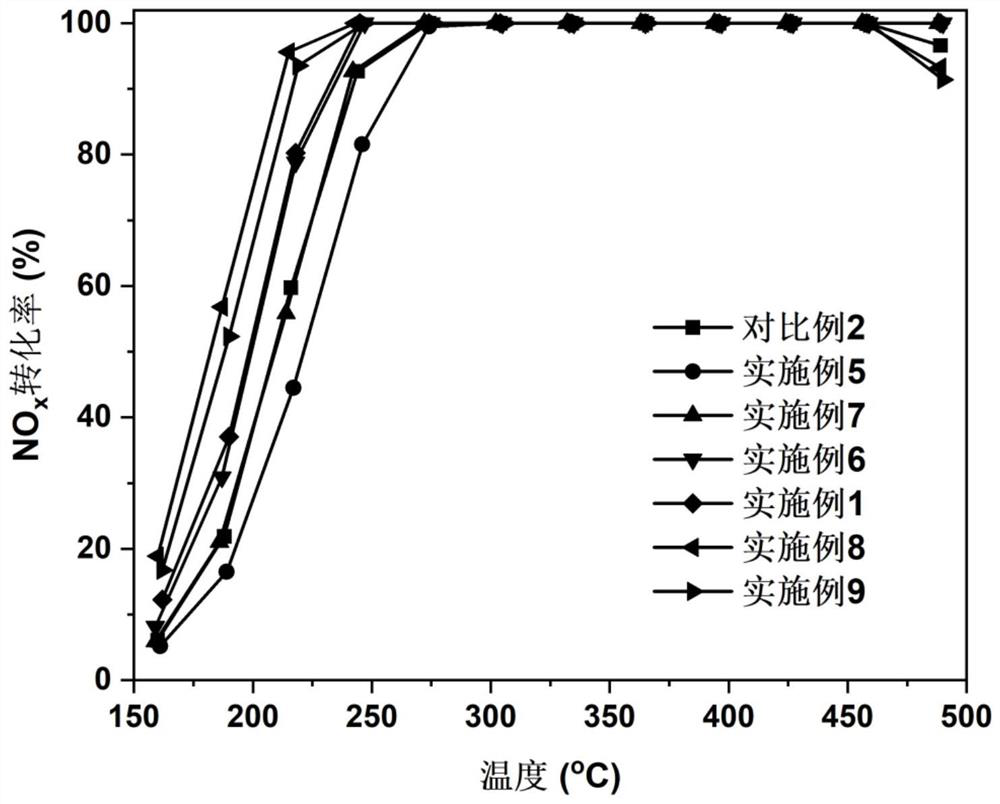

Embodiment 1

[0068] This embodiment provides a tin-containing metal oxide catalyst, and the tin-containing metal oxide catalyst is Ce 1 Sn 2 Nb 1 O x , where x is the number of O atoms required to satisfy the valence equilibrium of the element.

[0069] The preparation method of the tin-containing metal oxide catalyst comprises the following steps:

[0070] (1) mix cerium nitrate, niobium oxalate and tin tetrachloride pentahydrate according to formula quantity, obtain mixed solution;

[0071] (2) the mixed solution obtained in the precipitation treatment step (1) is obtained to obtain a solid;

[0072] (3) drying the solid matter obtained in step (2) at a temperature of 105° C. for 12 hours, and then calcining at a temperature of 700° C. for 2 hours to obtain the tin-containing metal oxide catalyst;

[0073] The described precipitation treatment of step (2) comprises the following steps:

[0074] After mixing ammonia water and the mixed solution obtained in step (1), stirring for 12 ...

Embodiment 2

[0076] This embodiment provides a tin-containing metal oxide catalyst, and the tin-containing metal oxide catalyst is Ce 1 Sn 2 Nb 1 O x , where x is the number of O atoms required to satisfy the valence equilibrium of the element.

[0077] In the preparation method of the tin-containing metal oxide catalyst, the step of precipitation treatment in step (2) is changed to: after mixing urea and the mixed solution obtained in step (1), heating and stirring at a temperature of 80-90° C. for 10 hours Filtration and washing were carried out in sequence to obtain solid matter, and the rest were the same as those in Example 1.

Embodiment 3

[0079] This embodiment provides a tin-containing metal oxide catalyst, and the tin-containing metal oxide catalyst is Ce 1 Sn 2 Nb 1 O x , where x is the number of O atoms required to satisfy the valence equilibrium of the element.

[0080] In the preparation method of the tin-containing metal oxide catalyst, the step of precipitation treatment in step (2) is changed to: after mixing citric acid monohydrate and the mixed solution obtained in step (1), heating at a temperature of 60-70° C. Stir until a spongy soft gel is formed, then filter and wash in sequence to obtain a solid, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com