Powder metallurgy friction material for new-generation high-speed motor train unit and preparation method of powder metallurgy friction material

A technology of high-speed EMUs and powder metallurgy, which is applied in the fields of climate sustainability, railway transportation, railway transportation, etc., can solve the problems of the new generation of high-speed EMUs with a speed of 400 kilometers per hour, the abnormal wear of friction pairs, and the reduction of friction coefficients. and other problems, to avoid abnormal wear, enhance strength, improve mechanical properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] (1) The low-loose ratio electrolytic copper powder is dendritic, and the bulk density is preferably 0.8-1.0g / cm 3 , the particle size is preferably not more than 75μm, and its specific surface area is preferably more than 3000cm 2 / g, while the specific surface area of ordinary electrolytic copper powder is only 1000 ~ 1800cm 2 / g, therefore, the electrolytic copper powder with low bulk ratio in the present invention has good plastic deformation ability, which is favorable for cold pressing, and the high surface energy brought by the high specific surface area has a stronger sintering driving force. In practical applications, the electrolytic copper powder with low bulk ratio used in the present invention can be the electrolytic copper powder with low bulk ratio that can be purchased through commercial means in the prior art.

[0032] (2) The copper-coated reduced iron powder is spongy, the iron content is preferably 80wt% to 90wt%, and the particle size is preferably...

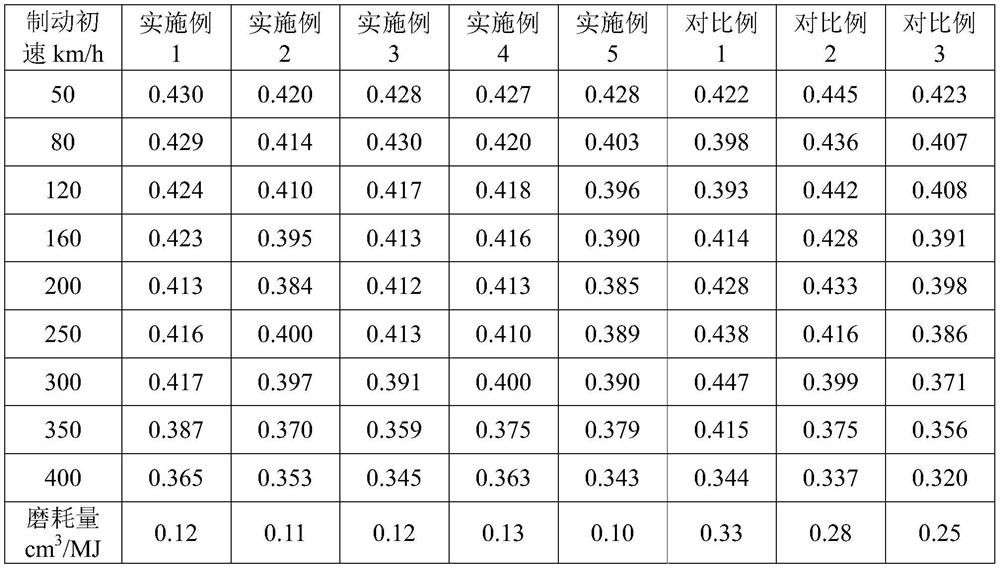

Embodiment 1

[0052] A powder metallurgy friction material for a new generation of high-speed EMUs is made of the following components in parts by mass: 58 parts of low-porosity electrolytic copper powder, 13 parts of copper-coated reduced iron powder, 5 parts of chromium alloy powder, and manganese sulfide ore. 1 part of powder, 5 parts of C / C-SiC abrasive powder, 2 parts of basalt fiber, 3 parts of magnesium oxide powder, 11 parts of graphite powder, and 2 parts of coke powder.

[0053] Specifically, the low-loose ratio electrolytic copper powder is dendritic, and the bulk density is 0.8-1.0g / cm 3 , the particle size is not more than 75μm, and its specific surface area exceeds 3000cm 2 / g. The copper-coated reduced iron powder is sponge-like, has an iron content of 80-90 wt%, and a particle size of 45-180 μm. The manganese sulfide ore powder adopts manganese sulfide primary ore powder, the particle size is not more than 15 microns, and the MnS weight ratio is 40% to 60%. The C / C-SiC ab...

Embodiment 2

[0061] A powder metallurgy friction material for a new generation of high-speed EMUs is made of the following components in parts by mass: 60 parts of low-porosity electrolytic copper powder, 15 parts of copper-coated reduced iron powder, 3 parts of chromium alloy powder, and manganese sulfide ore. 1 part of powder, 3 parts of C / C-SiC abrasive powder, 3 parts of basalt fiber, 2 parts of magnesium oxide powder, 10 parts of graphite powder, and 3 parts of coke powder.

[0062] Specifically, the low-loose ratio electrolytic copper powder is dendritic, and the bulk density is 0.8-1.0g / cm 3 , the particle size is not more than 75μm, and its specific surface area exceeds 3000cm 2 / g. The copper-coated reduced iron powder is sponge-like, the iron content is 80wt%-90wt%, and the particle size is 45-180μm. The manganese sulfide ore powder adopts manganese sulfide primary ore powder, the particle size is not more than 15 microns, and the MnS weight ratio is 40% to 60%. The C / C-SiC ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com