Multifunctional nano lubricating oil additive as well as preparation method and application thereof

A lubricating oil additive, multi-functional technology, applied in the fields of chemical and mechanical engineering, materials, can solve the problems of inability to reduce friction and anti-wear, poor dispersion stability, limited application, etc., to improve the anti-friction and anti-wear effect, easy to operate , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

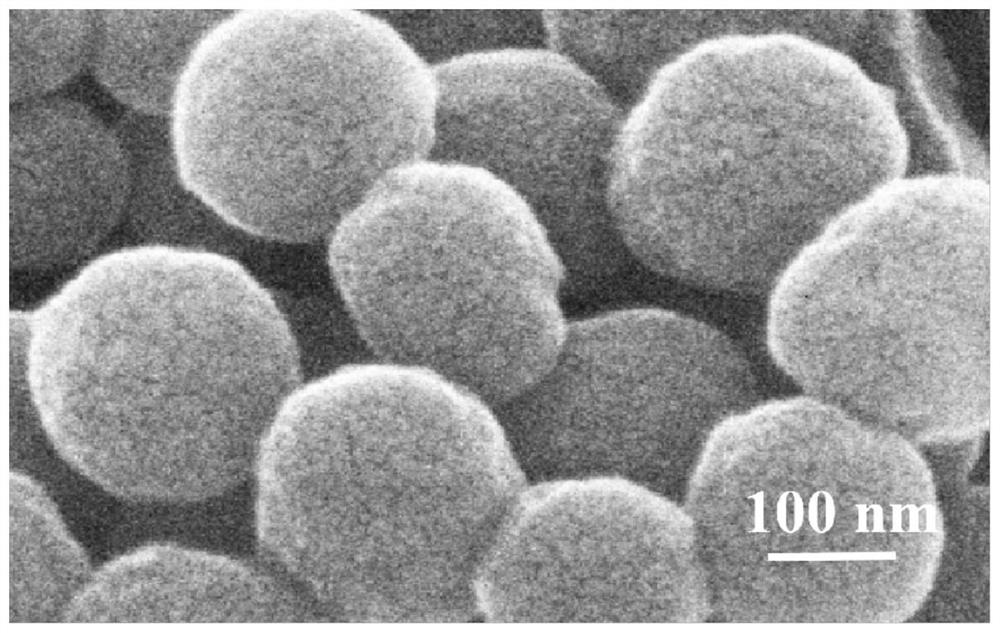

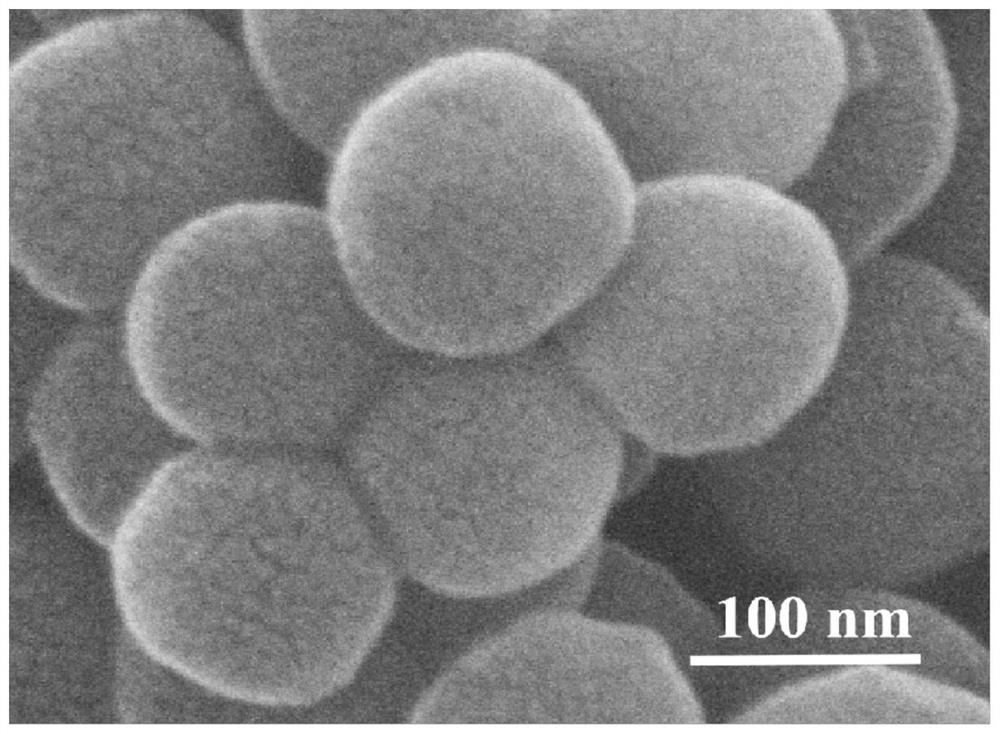

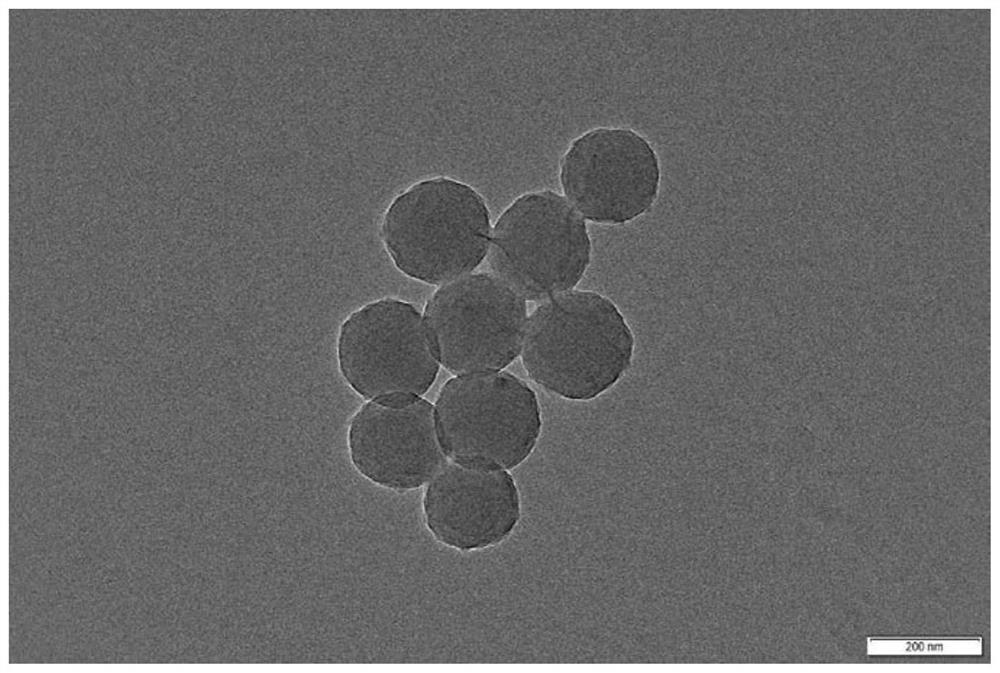

Image

Examples

Embodiment 1

[0046] (1) Preparation of covalent organic framework materials

[0047]Accurately weigh 93 mg of 3,6-bis(5-aldehyde thiophen-2-yl)-2,5bis(2-ethylhexyl)pyrrolo[3,4-c]pyrrole-1,4(2H, 5H)-dione, add 103 mL of chloroform to dissolve. Accurately weigh 32 mg of tris(4-aminophenyl)amine, add 105 mL of methanol to dissolve, and drop into the above chloroform solution. After mixing evenly, 15 mL of glacial acetic acid was added dropwise for catalysis, and it was placed on a magnetic stirrer and stirred for 72 h to make it fully react. After the reaction, centrifuge with a high-speed centrifuge at 8000 rpm for 12 min, take out the supernatant in the centrifuge tube, add 60 mL of tetrahydrofuran to wash, and continue centrifugation. Repeat this operation 3 times, the tetrahydrofuran washing solution is nearly colorless, and then add deionized water to carry out the above operation. Remove the supernatant, and the lower sediment is the covalent organic framework material.

[0048] (2)...

Embodiment 2

[0055] (1) Preparation of covalent organic framework materials

[0056] Accurately weigh 82 mg of 3,6-bis(5-aldehyde thiophen-2-yl)-2,5bis(2-ethylhexyl)pyrrolo[3,4-c]pyrrole-1,4(2H, 5H)-dione, add 80 mL of chloroform to dissolve. Accurately weigh 25 mg of tris(4-aminophenyl)amine, add 80 mL of methanol to dissolve, and drop it into the above chloroform solution. After mixing uniformly, 10 mL of glacial acetic acid was added dropwise for catalysis, and it was placed on a magnetic stirrer and stirred for 60 h to make it fully react. After the reaction, centrifuge with a high-speed centrifuge at 6500 rpm for 15 min, take out the supernatant in the centrifuge tube, add 45 mL of tetrahydrofuran to wash, and continue centrifugation. Repeat this operation 3 times, the tetrahydrofuran washing solution is nearly colorless, and then add deionized water to carry out the above operation. Remove the supernatant, and the lower sediment is the covalent organic framework material.

[0057...

Embodiment 3

[0064] (1) Preparation of covalent organic framework materials

[0065] Accurately weigh 100 mg of 3,6-bis(5-aldehyde thiophen-2-yl)-2,5bis(2-ethylhexyl)pyrrolo[3,4-c]pyrrole-1,4(2H, 5H)-dione, add 103 mL of carbon tetrachloride to dissolve. Accurately weigh 32 mg of tris(4-aminophenyl)amine, add 105 mL of n-propanol to dissolve, and drop it into the above carbon tetrachloride solution. After mixing evenly, 10.5 mL of glacial acetic acid was added dropwise for catalysis, and it was placed on a magnetic stirrer and stirred for 72 h to make it fully react. The solution was centrifuged with a high-speed centrifuge at 9000 rpm for 10 min, the supernatant in the centrifuge tube was taken out, 60 mL of tetrahydrofuran was added to wash, and centrifugation was continued. Repeat this operation 3 times, the tetrahydrofuran washing solution is nearly colorless, and deionized water is added to carry out the above operation. Remove the supernatant, and the lower sediment is the covalen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com