Impact-resistant polypropylene regenerated material recycled from ocean and preparation method of impact-resistant polypropylene regenerated material

A technology for recycling polypropylene and polypropylene, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of reduced performance, inability to meet recycling and reuse, and no use value, and achieve the effect of increasing use value and reducing containment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

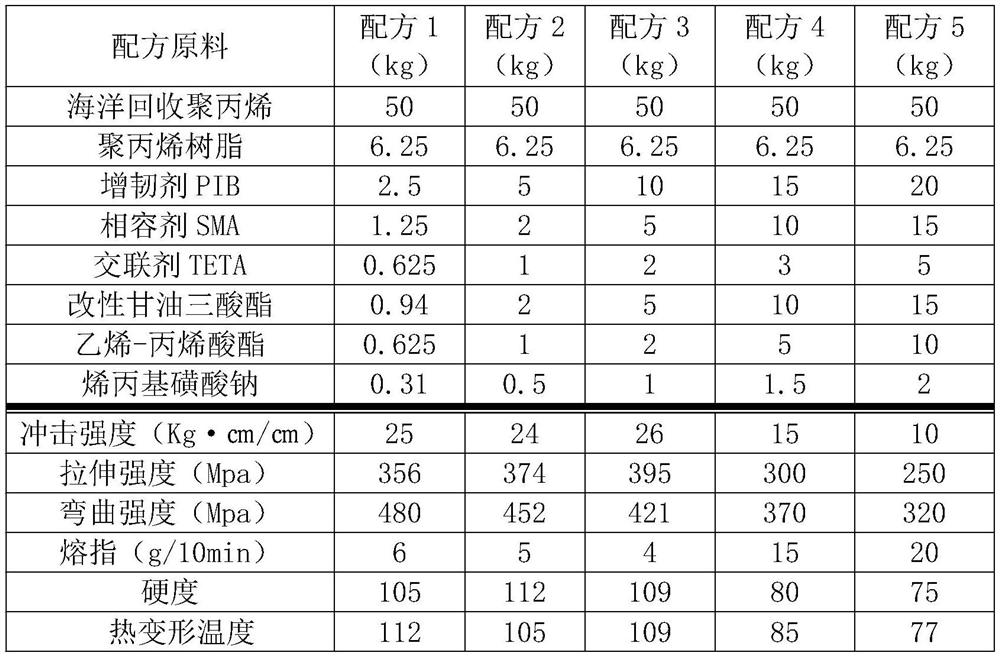

[0057] 1. Marine recycled polypropylene was pre-dried at 90°C for 60min, accurately weighed according to the formula in Table 2, marine recycled PP, PP resin, PIB (polyisobutylene), SMA (styrene grafted maleic anhydride), TETA (tetraethylene) Pentaamine), modified triglycerides, ethylene-acrylates, sodium allyl sulfonate.

[0058] 2. Preparation method

[0059] Step 1, put the marine recycled plastic PP into the oven and bake at 90℃ for 60min.

[0060] Step 2, add the baked marine plastic PP and PP resin, SMA, TETA into the mixing bucket, stir for 5 minutes, then add the modified triglyceride, mix and stir for 5 minutes,

[0061] Step 3, mix ethylene-acrylate and sodium allyl sulfonate into the mixing tank, and stir for 10 min.

[0062] Step 4: Add the well-stirred mixture to twin-screw extrusion, feed the material for melt extrusion, set the temperature to 180-220°C, set the screw speed to 300 rpm, extrude and cool, dry with drying air, and cut into pellets. .

[0063] Th...

Embodiment 2

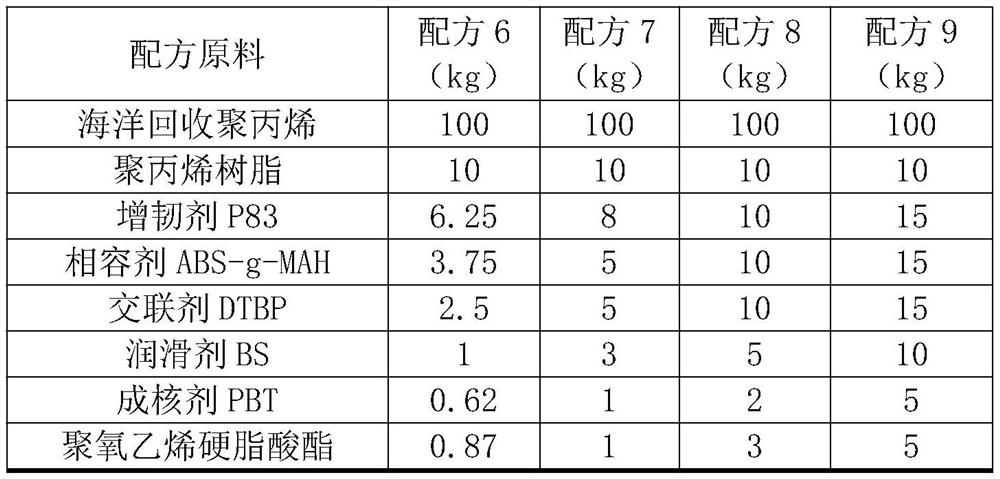

[0071] 1. The polypropylene recovered from the ocean was pre-dried at 90°C for 100 min, and the recovered PP, PP resin, P83 (nitrile rubber), ABS-g-MAH (maleic anhydride grafted styrene-butylene) were accurately weighed according to the formula in Table 4. Diene-acrylonitrile terpolymer), DTBP (di-tert-butyl peroxide), BS (n-butyl stearate), PBT (polybutylene terephthalate), polyoxyethylene stearic acid ester.

[0072] 2. Preparation method

[0073] Step 1, put the marine recycled plastic PP into the oven and bake at 90℃ for 100min.

[0074] Step 2, add the baked marine plastic PP and PP resin, P83, ABS-g-MAH, DTBP into the mixing bucket, stir for 5 minutes, then add BS, mix and stir for 5 minutes,

[0075] Step 3, mix PBT and polyoxyethylene stearate into the mixing bucket, and stir for 10 min.

[0076] Step 4: Add the well-stirred mixture to twin-screw extrusion, feed the material for melt extrusion, set the temperature to 180-220°C, and set the screw speed to 320 rev / min...

Embodiment 3

[0085] 1. The polypropylene recovered from the ocean was pre-dried at 90°C for 60 min, and accurately weighed according to the formula in Table 6. The recovered PP from the ocean, PP resin, SEBS (hydrogenated styrene-butadiene block copolymer), ASA-g-MAH ( Acrylonitrile-styrene-acrylate copolymer-maleic anhydride graft copolymer), DTBP (di-tert-butyl peroxide), fatty acid polyglycol ester, 2,6-naphthalene dicarboxamide-based compound, GMS ( Glycerol monostearate).

[0086] 2. Preparation method

[0087] Step 1, put the marine recycled plastic PP into the oven and bake at 90℃ for 60min.

[0088] Step 2, add the baked marine plastic PP and PP resin, SEBS, ASA-g-MAH, DTBP into the mixing bucket, stir for 5 minutes, then add fatty acid polyglycol ester, mix and stir for 5 minutes,

[0089] Step 3, mix the 2,6-naphthalenedicarboxamide compound and GMS (glycerol monostearate) into the mixing tank, and stir for 10min,

[0090] Step 4: Add the well-stirred mixture to twin-screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com