Method for culturing organoid by using elastin hydrogel

A technology of elastin and hydrogel, applied in the biological field, can solve the problems of intramolecular cross-linking, large molecular weight, and many reaction steps, and achieve improved cell adhesion, high efficiency of modified grafting, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

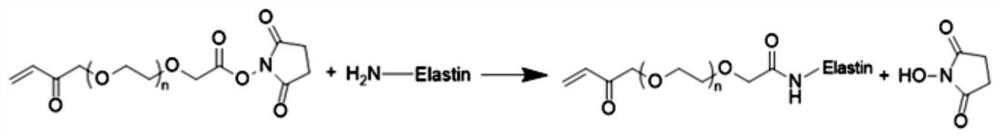

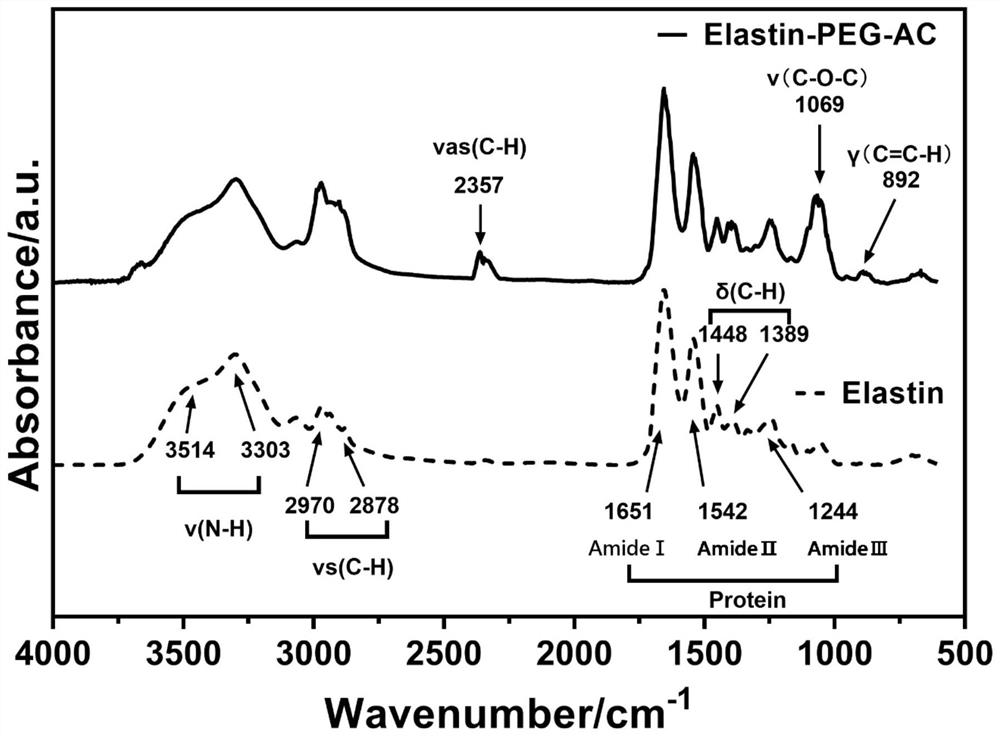

[0041] This embodiment provides a modification method of photocrosslinkable elastin, which is prepared according to the following steps: 0.05 g of soluble elastin is dissolved in 10 mL of 0.01 M phosphate physiological buffer at pH 8.0 to prepare an aqueous elastin solution. 0.01 g of methacrylate-polyethylene glycol-N-hydroxysuccinimide (polyethylene glycol polymerization degree of 4) was added to the above-mentioned elastin aqueous solution, and the reaction was stirred for 3 hours under normal temperature and nitrogen atmosphere. The reactants were dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa for 48 hours, and then the purified protein solution was lyophilized in a freeze dryer to obtain modified elastin.

Embodiment 2

[0043] This embodiment provides a modification method for photocrosslinkable elastin, which is prepared according to the following steps: 0.2 g of soluble elastin is dissolved in 10 mL of 0.01 M phosphate physiological buffer at pH 8.0 to prepare an aqueous elastin solution. 0.1 g of methacrylate-polyethylene glycol-N-hydroxysuccinimide (polyethylene glycol polymerization degree of 20) was added to the above-mentioned elastin aqueous solution, and the reaction was stirred for 0.5 hour under normal temperature and nitrogen atmosphere. The reactants were dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa for 48 hours, and then the purified protein solution was lyophilized in a freeze dryer to obtain modified elastin.

Embodiment 3

[0045] This example provides a modification method of photocrosslinkable elastin, which is prepared according to the following steps: 0.15 g of soluble elastin is dissolved in 10 mL of 0.01M phosphate physiological buffer at pH 8.3 to prepare an aqueous elastin solution. 0.08 g of methacrylate-polyethylene glycol-N-hydroxysuccinimide (polyethylene glycol polymerization degree of 10) was added to the above-mentioned elastin aqueous solution, and the reaction was stirred for 2 hours under normal temperature and nitrogen atmosphere. The reactants were dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa for 48 hours, and then the purified protein solution was lyophilized in a freeze dryer to obtain modified elastin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com