Molecularly imprinted electrochemical sensor based on magnetic mesoporous titanium dioxide material as well as preparation method and application of molecularly imprinted electrochemical sensor

A mesoporous titanium dioxide and molecular imprinting technology, applied in the direction of electrochemical variables of materials, can solve the problems of difficult separation and recovery, long detection period, limited recognition sites for surface molecularly imprinted polymers, etc., and achieve rich and dispersed recognition sites. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

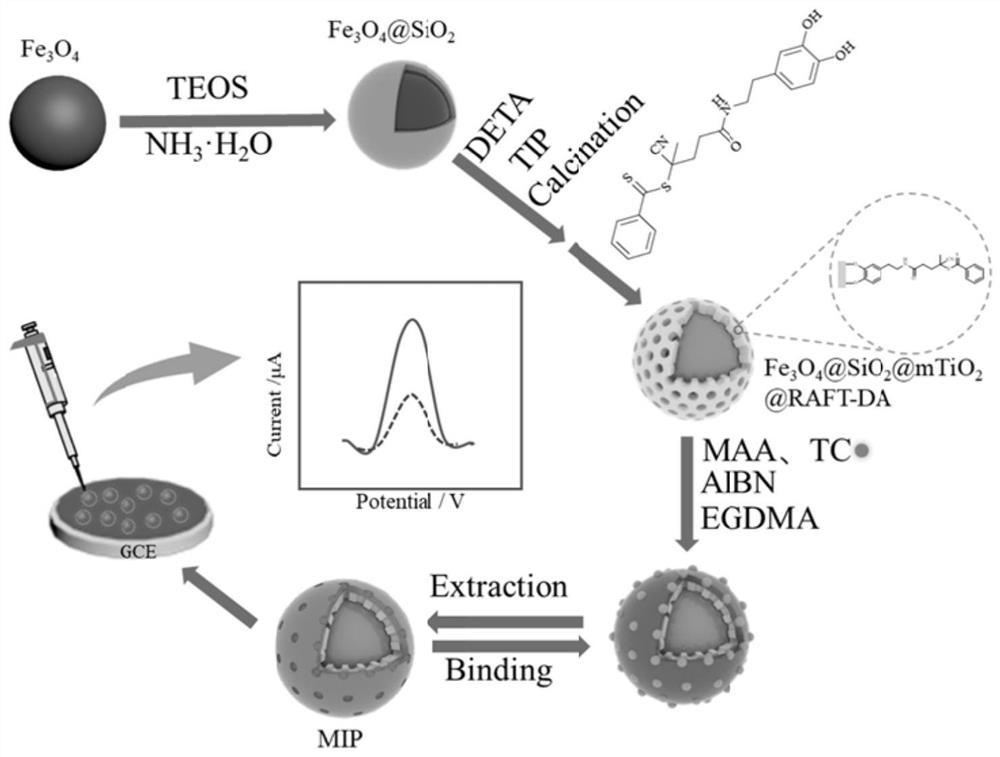

[0056] The present invention also provides a preparation method of a molecularly imprinted electrochemical sensor based on a magnetic mesoporous titanium dioxide material, comprising the following steps:

[0057] Step 1. Preparation of Fe by solvothermal method 3 O 4 magnetic nanoparticles;

[0058] Step 2, by sol-gel method in Fe 3 O 4 The surface of magnetic nanoparticles is coated with silica to obtain magnetic nano-microsphere Fe coated with silica 3 O 4 @SiO 2 ;

[0059] Step 3. By solvothermal method, the silica-coated magnetic nano-microspheres Fe 3 O 4 @SiO 2 The surface is coated with titanium dioxide, the Fe 3 O 4 @SiO 2 Disperse into isopropanol, add diethylenetriamine and tetraisopropyl titanate in turn, move into a stainless steel hydrothermal kettle, and obtain magnetic nanometer microspheres Fe coated with titanium dioxide. 3 O 4 @TiO 2 ; Then magnetically separated, washed, dried and heat-treated to obtain magnetic mesoporous titanium dioxide nan...

Embodiment 1

[0069] In this example, the preparation method of the molecularly imprinted electrochemical sensor based on the magnetic mesoporous titanium dioxide material is described in detail. figure 1 shown, attached figure 1 This is a schematic diagram of the preparation process of the electrochemical sensor based on the magnetic mesoporous molecularly imprinted polymer modification according to the present invention; the specific steps in this embodiment are as follows:

[0070] Step 1. Preparation of Fe by solvothermal method 3 O 4 magnetic nanoparticles;

[0071] Specifically, first, weigh 2.6g anhydrous ferric chloride, 1.0g sodium citrate and 4.0g anhydrous sodium acetate; dissolve the weighed anhydrous ferric chloride, sodium citrate and anhydrous sodium acetate in 80mL of ethylene glycol, sonicated for 30min to fully dissolve to obtain a homogeneous solution;

[0072] Then, the above homogeneous solution was poured into a stainless steel hydrothermal kettle to carry out the ...

Embodiment 2

[0126] The steps of this embodiment are substantially the same as those of embodiment 1, and the difference lies in the ratio of tetracycline, methacrylic acid, ethylene glycol dimethacrylate and azobisisobutyronitrile in step 6.

[0127] Specifically, in step 6, 172 mg of methacrylic acid and TC were dissolved in 50 mL of anhydrous toluene, and under the protection of nitrogen, mechanically stirred for 24 h; 50 mg of RAFT reagent-modified magnetic mesoporous titanium dioxide carrier Fe was added. 3 O 4 @mTiO 2 -CPPA, disperse it in the above-mentioned solution; then add 0.9911g ethylene glycol dimethacrylate and 13mg azobisisobutyronitrile, carry out polymerization reaction under nitrogen atmosphere, obtain reaction product; Washing and vacuum drying to obtain the magnetic mesoporous molecularly imprinted polymer Fe 3 O 4 @mTiO 2 @MIP; where the polymerization temperature was 70 °C and the reaction time was 24 h. The imprinted polymers obtained at different ratios showed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com