Magnetic surface molecular imprinting electrochemical sensor as well as preparation method and application thereof

A surface molecular imprinting and electrochemical technology, which is applied in the direction of material electrochemical variables, scientific instruments, and material analysis through electromagnetic means, can solve the problems of high cost of detection equipment and cumbersome sample processing, and achieve high sensitivity and specificity detection , low raw material cost, template molecular mass transfer rate block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

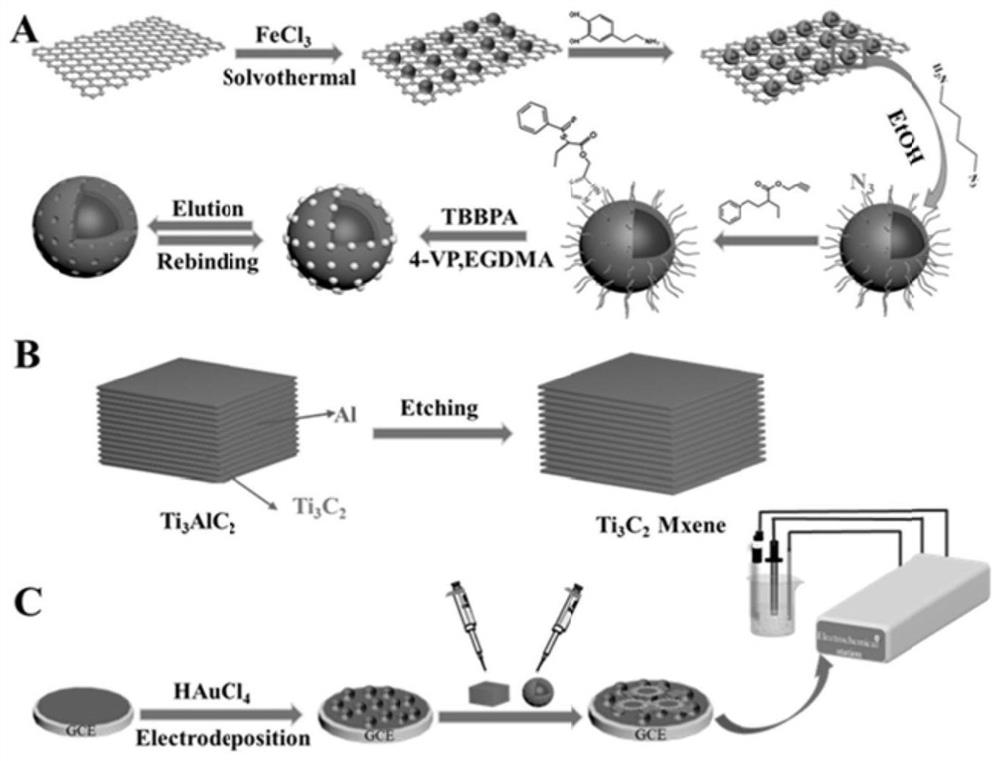

[0047] The present invention also provides a preparation method of a magnetic surface molecularly imprinted electrochemical sensor, comprising the following steps:

[0048] Step 1. Graphene oxide GO is prepared by Hummers method.

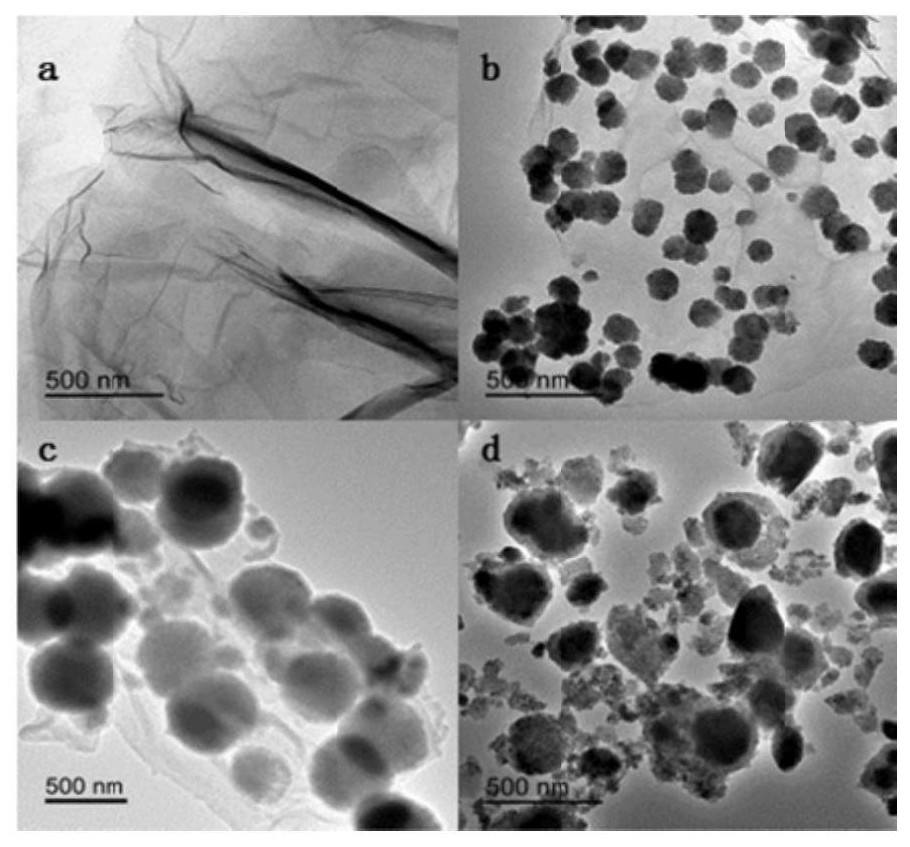

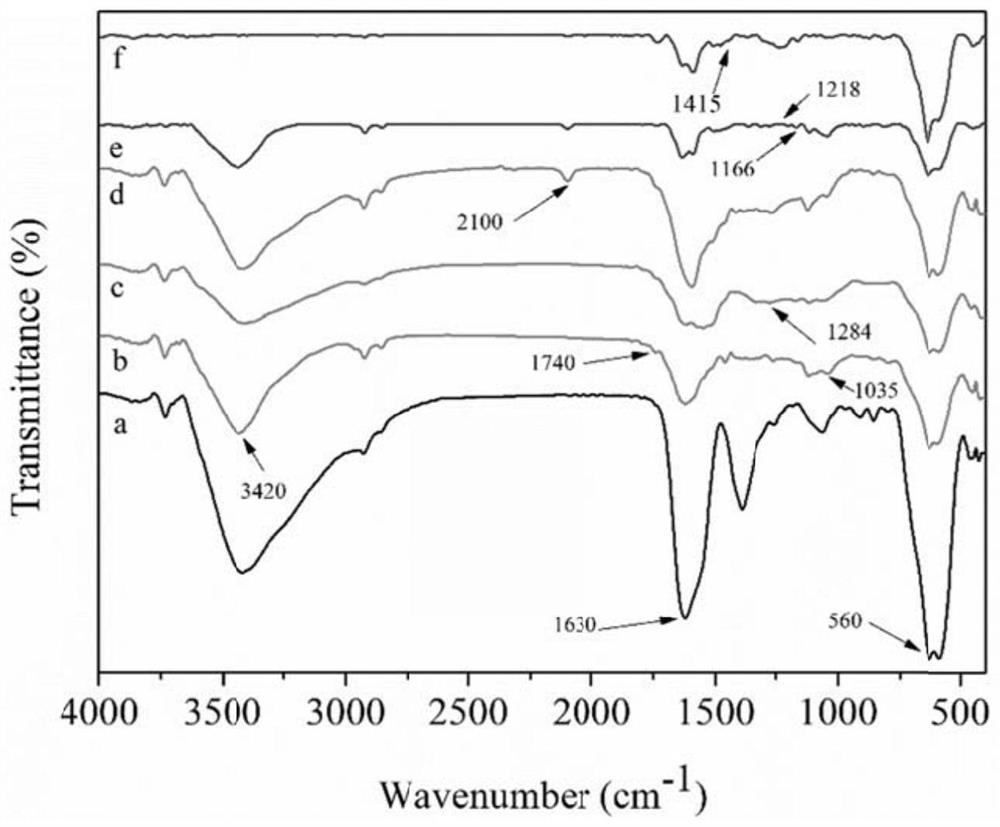

[0049] Step 2. Using solvothermal method, Fe 3 O 4 Magnetic nanoparticles were introduced into graphene oxide GO to prepare magnetic graphene oxide nanomaterials GO@Fe 3 O 4 .

[0050] Among them, the preparation of magnetic graphene oxide nanomaterials GO@Fe 3 O 4 process, as follows:

[0051] The graphene oxide GO was mixed with ethylene glycol, and after ultrasonic stirring for 30 min, FeCl was added. 3 ·6H 2 O and NaAc continued to be ultrasonically stirred for 15 min; after that, reacted at a temperature of 180-200 ° C for 1.5-2 h, magnetic separation, washing, and vacuum drying to obtain the magnetic graphene oxide nanomaterial GO@Fe 3 O 4 .

[0052] Step 3, using dopamine to modify the magnetic graphene oxide nanomaterial to obtain...

Embodiment 1

[0064] as attached figure 1 As shown, this embodiment 1 provides a preparation method of a magnetic surface molecularly imprinted electrochemical sensor, which specifically includes the following steps:

[0065] Step 1, using Hummers method to prepare graphene oxide GO;

[0066] The preparation process of graphene oxide GO is as follows:

[0067] Put 2g of NaNO 3 and 96mL of concentrated H 2 SO 4 and 2g of graphite phosphorus flakes were mixed and stirred at 0°C for 30min to obtain a mixed system A;

[0068] Put 12g of KMnO 4 It was added into the mixed system A in 3 times, stirred for 1.5 h, and then reacted at a constant temperature of 35 °C for 2 h; after that, 80 mL of pure water was added, and the reaction system was continued to react for 1 h after the reaction system reached 90 °C to obtain system one;

[0069] Put 20mL of H 2 O 2 Add to 200mL of deionized water, add 20mL of concentrated hydrochloric acid to 92mL of deionized water, then add to the above system on...

Embodiment 2

[0102] The steps of Example 2 are substantially the same as those of Example 1, and the difference lies in the pH of the PBS in Step 8.

[0103] Specifically, the pH of 6.0, 6.5, 7.0, 7.5 and 8.0 were prepared containing 5.0 mmol L -1 [Fe(CN) 6 ] 3- / 4-Buffer solution, modified Au / Mxene and the magnetic surface molecularly imprinted polymer GO@Fe on the surface of glassy carbon electrode 3 O 4 @MIP, phosphate buffer with pH of 6.0, 6.5, 7.0, 7.5 and 8.0 was used as the electrolyte in this experiment, the modified glassy carbon electrode was used as the working electrode, the platinum wire electrode was used as the counter electrode, and the Ag / AgCl electrode was used as the electrode. As a reference electrode, the optimal pH value of TBBPA was determined electrochemically, in which pH=7 had the best current response and was selected as the optimal pH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com