Magnetic surface molecularly imprinted polymer and preparation method and application thereof

A surface molecular imprinting and polymer technology, which is applied to the preparation of alkali metal compounds, chemical instruments and methods, and test samples, can solve the problems of limited recognition sites of surface molecular imprinting polymers and difficulty in separation and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

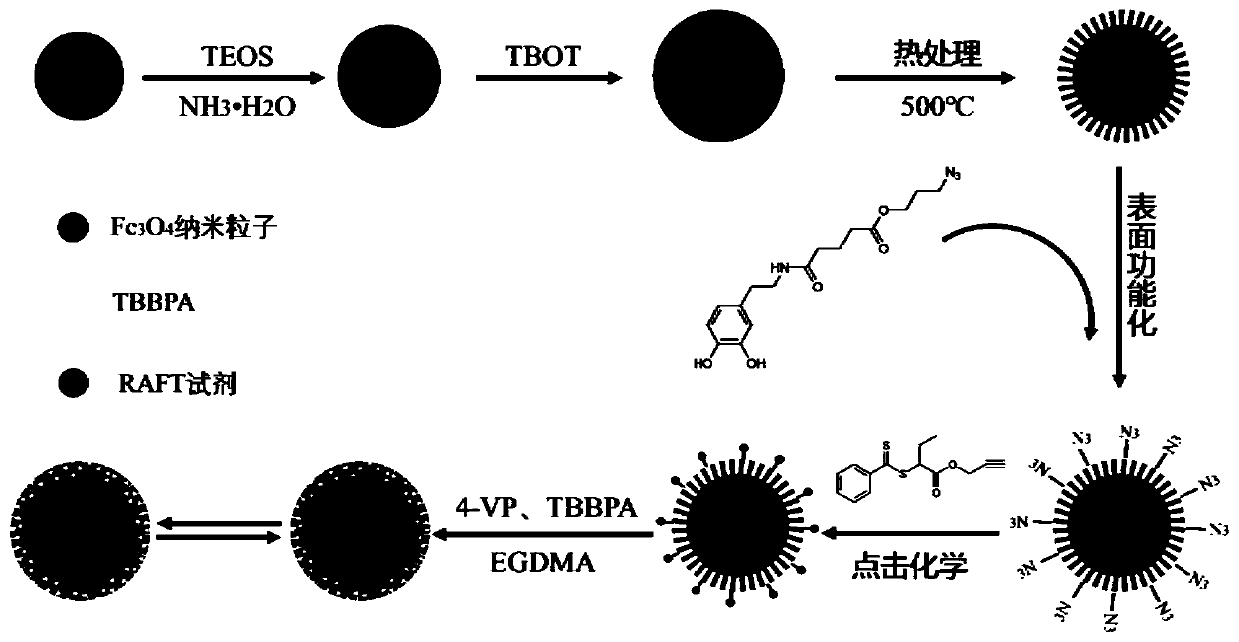

[0035] The present invention also provides a method for preparing a molecularly imprinted polymer on a magnetic surface, comprising the following steps:

[0036] Step 1, prepare Fe by solvothermal method 3 o 4 magnetic nanoparticles;

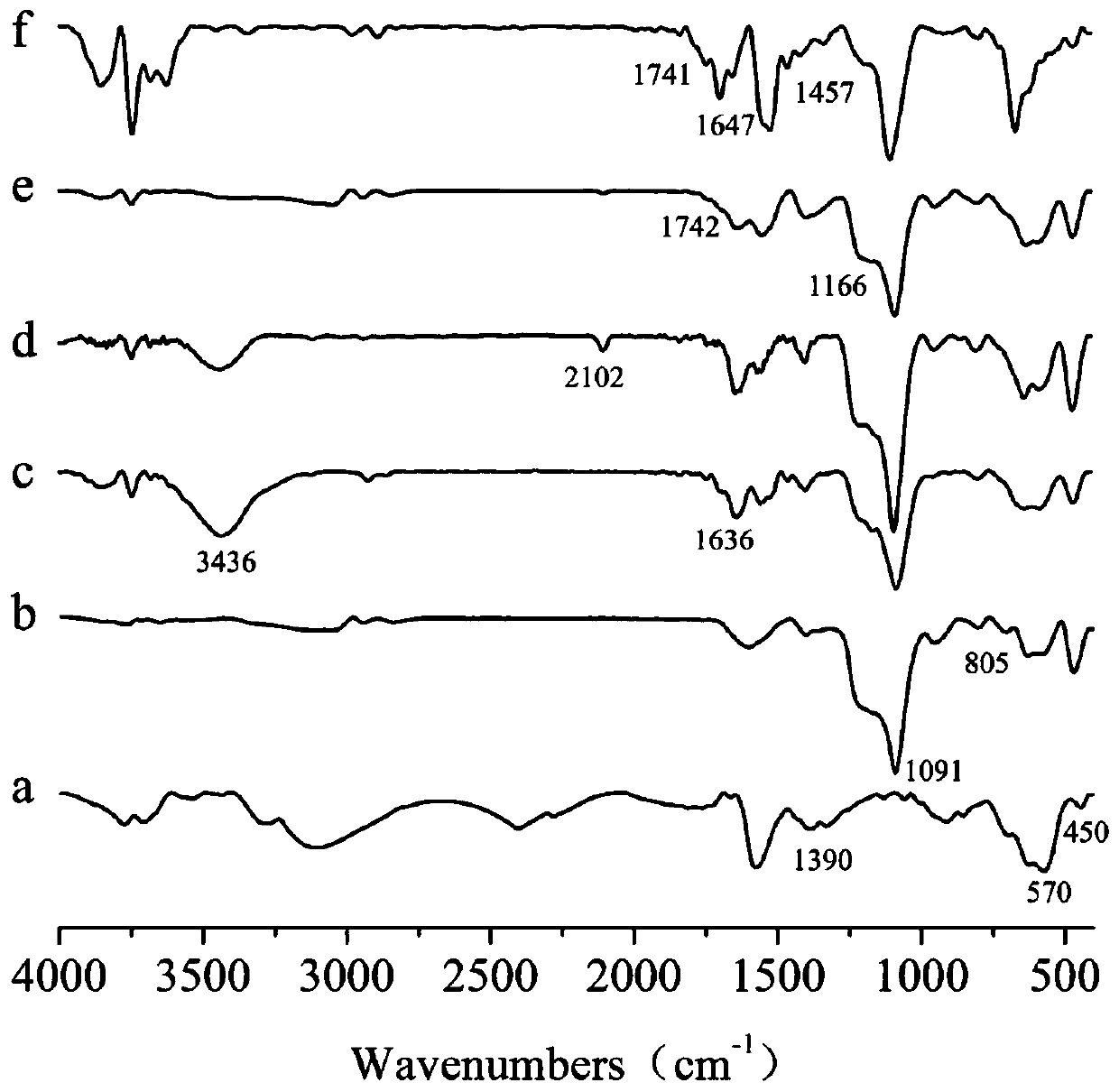

[0037] Step 2, by sol-gel method in Fe 3 o 4 The surface of the magnetic nanoparticles is coated with silica, and the magnetic nanospheres coated with silica are obtained. 3 o 4 @SiO 2 ;

[0038] Step 3, the magnetic nano-microspheres Fe coated with silicon dioxide 3 o 4 @SiO 2 Disperse in absolute ethanol, add ammonia water and tetrabutyl titanate, and carry out hydrolysis reaction to obtain magnetic nanospheres Fe coated with titanium dioxide. 3 o 4 @TiO 2 ; Then through magnetic separation, washing, drying and heat treatment, the magnetic mesoporous titania nanosphere Fe 3 o 4 @mTiO 2 ;

[0039] Step 4, the magnetic mesoporous titania nano-microspheres Fe 3 o 4 @mTiO 2 Ultrasonic dispersion into anhydrous dichloromethane, a...

Embodiment 1

[0047] This example describes in detail the preparation method of molecularly imprinted polymers on magnetic surfaces, as shown in the attached figure 1 shown, with figure 1 It is a schematic diagram of the preparation process of the molecularly imprinted polymer on the magnetic surface of the present invention; the specific steps in this embodiment are as follows:

[0048] Step 1, adopt solvothermal method to prepare Fe 3 o 4 magnetic nanoparticles;

[0049] Specifically, first, weigh 2.6g anhydrous ferric trichloride, 1.0g sodium citrate and 4.0g anhydrous sodium acetate; dissolve the weighed anhydrous ferric chloride, sodium citrate and anhydrous sodium acetate in In 80mL ethylene glycol, sonicate for 15-30min to fully dissolve and obtain a uniform solution;

[0050] Then, pour the above homogeneous solution into a stainless steel autoclave for reaction; wherein, the reaction temperature is 180-200°C, and the reaction time is 10-24h; after the reaction is completed, coo...

Embodiment 2

[0098] The steps of this embodiment are substantially the same as those of Embodiment 1, except that the ratio of 4-vinylpyridine to ethylene glycol dimethacrylate in step 6 is different.

[0099] Specifically, in step 6, dissolve 0.21g of 4-vinylpyridine and TBBPA in 50mL of anhydrous toluene, and mechanically stir for 12-24h under the protection of nitrogen; add 50mg of RAFT reagent-modified magnetic mesoporous titanium dioxide carrier Fe 3 o 4 @mTiO 2 -CPDB, which is dispersed in the above solution; then add 0.369g ethylene glycol dimethacrylate and 20mg azobisisobutyronitrile, and carry out polymerization reaction under nitrogen atmosphere to obtain the reaction product; adopt ethanol to carry out the reaction product Washing, vacuum drying to obtain the magnetic surface molecularly imprinted polymer Fe 3 o 4 @mTiO 2 @MIP; where the polymerization temperature is 60-70°C and the reaction time is 16-32h. The imprinted polymers obtained at different ratios showed differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com