Patterned flexible sensor prepared by femtosecond and nanosecond laser and preparation method thereof

A flexible sensor and patterning technology, applied in photovoltaic power generation, final product manufacturing, printed circuit manufacturing, etc., can solve the problems of light transmission performance increase, light transmission performance decline, conductive performance decline, etc., to achieve good and excellent light transmission performance The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

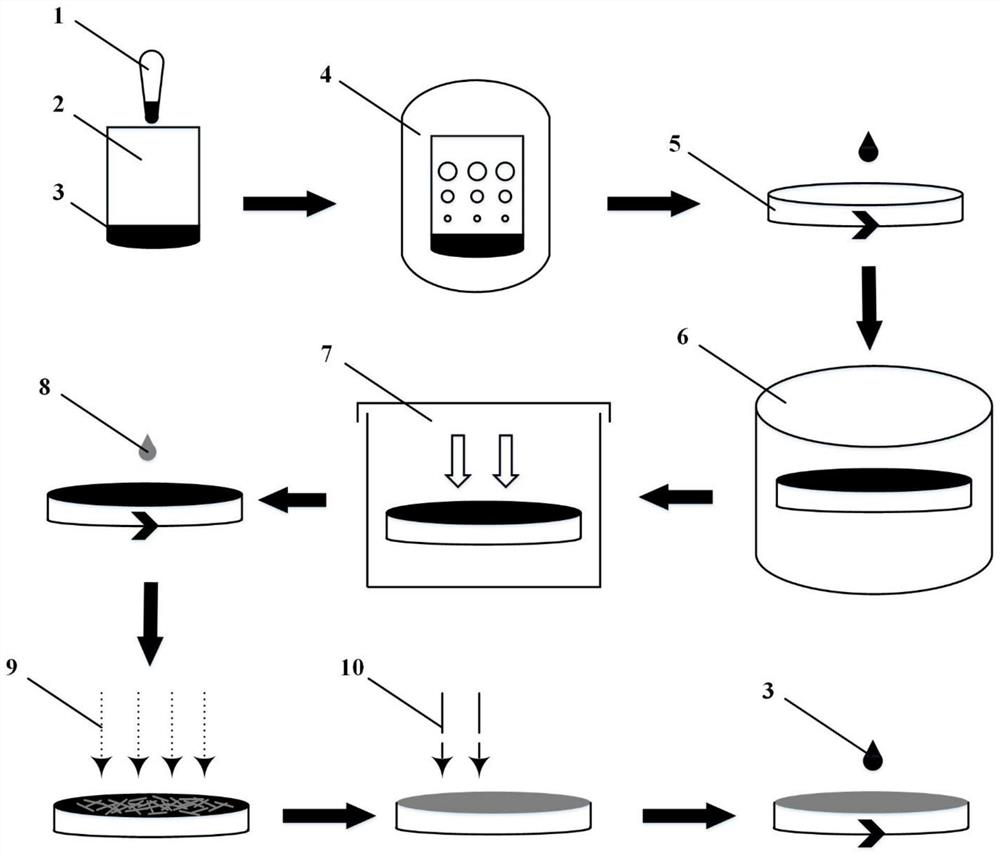

[0034] like figure 1 As shown, a method for preparing a patterned transparent conductive film by laser provided in this embodiment specifically includes the following steps:

[0035] S1-1. Use a pipette to transfer 0.5 mg of curing agent 1 into a plastic cup 2 containing 7.5 mg of PDMS monomer 3, and stir well to make the curing agent 1 and PDMS monomer 3 fully mixed (the PDMS monomer and cured All agents belong to Dow Corning 184PDMS glue);

[0036] S1-2. Place the plastic cup 2 together with the well-mixed curing agent 1 and PDMS 3 in the reaction tower 4 to remove the air bubbles in the mixed solution;

[0037] S1-3. Spin-coat the bubble-free PDMS mixture 5 onto the clean silicon wafer 6, set the rotation speed of the silicon wafer to be 500 rpm, and the spin-coating time to be 120 s;

[0038] S1-4. After the spin coating is completed, put the silicon wafer 6 coated with the PDMS mixed solution 5 into the vacuum oven 7 . Set the vacuum oven temperature to 100°C and the b...

Embodiment 2

[0047] like figure 1 As shown, a method for preparing a patterned transparent conductive film by laser provided in this embodiment specifically includes the following steps:

[0048] S1-1. Use a pipette to transfer 0.6 mg of curing agent 1 into a plastic cup 2 containing 7.2 mg of PDMS monomer 3, and stir well to fully mix curing agent 1 and PDMS monomer 3 (the PDMS monomer and cured All agents belong to Dow Corning 184PDMS glue);

[0049] S1-2. Place the plastic cup 2 together with the well-mixed curing agent 1 and PDMS 3 in the reaction tower 4 to remove the air bubbles in the mixed solution;

[0050] S1-3. Spin-coat the bubble-free PDMS mixture 5 onto the clean silicon wafer 6, set the rotation speed of the silicon wafer to be 600 rpm, and the spin-coating time to be 100 s;

[0051] S1-4. After the spin coating is completed, put the silicon wafer 6 coated with the PDMS mixed solution 5 into the vacuum oven 7 . Set the temperature of the vacuum oven to 100°C and the bakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com