On-line soft measurement method of pH value and H2 S03 concentration in acrylonitrile polymerization system

A technology of H2SO3 and acrylonitrile, which is applied to the analysis of materials and instruments, and can solve problems such as changes in polymerization parameters, inability to understand the polymerization process, and unstable spinning quality in subsequent processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

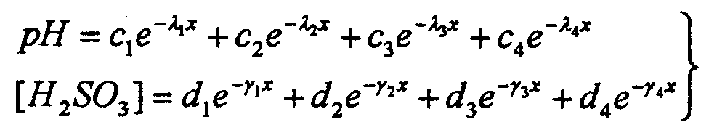

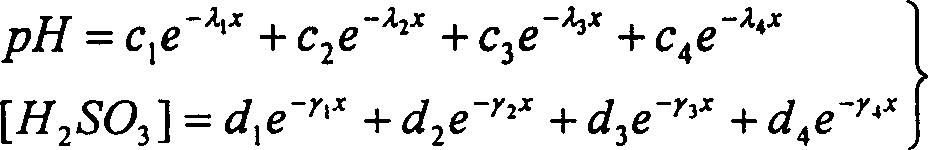

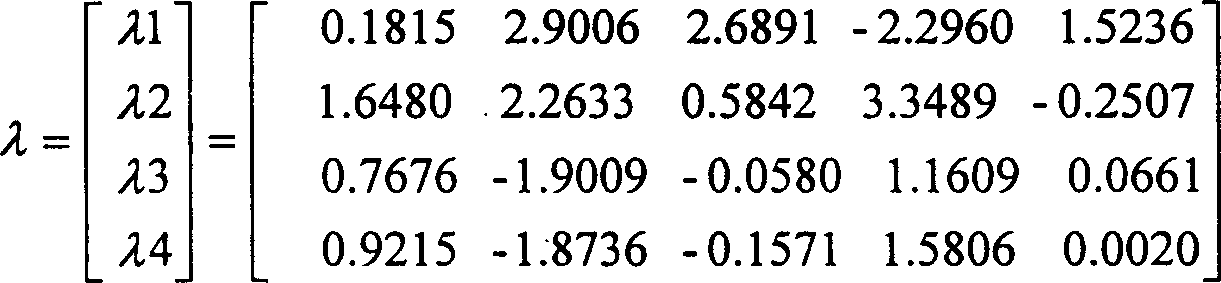

Method used

Image

Examples

Embodiment Construction

[0044] 1. Detect data, use conventional detection devices to detect operating variables, the specific operating variables are methyl acrylate (MA), acrylonitrile (AN), recovered monomer (RM), oxidant sodium chlorate (A2), reducing agent coke Eight kinds of material flows into the polymerization kettle, such as sodium bisulfite (A3), sodium methacrylic acid sulfonate (A1), beta hydroxyethane mercaptan (A4) and pure water (DW), and the reaction temperature of the polymerization kettle (A5 );

[0045] 2. Data preprocessing, convert the detected operating variables into percent concentration, and do normalization. The operating variables detected above can be sent to the computer, and the following variables can be converted by the computer:

[0046] ① Calculate the total flow;

[0047] ② Calculate the percentage concentration of sodium methacrylate sulfonate (A1) in the polymerization kettle;

[0048] ③ Calculate the percentage concentration of oxidant sodium chlorate (A2) in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com